Abstract

A vibration technique is used in this study to explore the effect of low frequency vibration on the mechanical reliability of Al-7Si-Mg castings. The quality of castings is related to the number and the size of porosity and oxide film in thin wall investment casting. The quality of each method of casting (casting with and without vibration) was assessed by the density of the defects within the thin strips. Weibull distribution function is used to analyze the tensile strength data. The Weibull modulus is applied as a criterion to assess the mechanical reliability to identify the optimized casting condition. The results show that the effect of the vibration on the mechanical reliability is markedly dependent on acceleration of vibration, and the Weibull modulus is in the range of 12 to 12.7 when the acceleration is in range of 0 to 1 g; however, in more than 1 g, the range is 30–35.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Green N, Campbell J (1994) Influence of oxide film filling defect on the strength of Al-7%Si-Mg alloys casting. Trans AFS 102:341–347

Campbell J (2004) Properties of cast metals, 66th World Foundry Congress, 6–9 September, Istanbul, Turkey

Campbell J (2003) Casting defect in vacuum-investment-cast Ni-base turbine blade. Trans Metall

Campbell J (1988) Thin wall casting. Mater Sci Technol 4:194–204

Flemings MC (1974) Solidification process. McGraw-Hill, New York, pp 219–229

Campbell J (1995) Review of fluidity concepts in casting. Cast Metals 4:227–237

Iida T, Guthrie RIL (1988) The physical properties of liquid metals. Oxford University Press, Cambridge

Keene BJ (1993) Review of data for the surface tension of pure metals. Int Mater Rev 38:157–192

Khalili, Kromp K (1991) Statistical properties of Weibull estimation. J Mater Sci 26:6741–6452

Campbell, Li DZ (2004) Filling system for investment casting Ni-base turbine blade. J Mater Process Technol 148:310–316

Green N, Campbell J (1993) Statistical distributions of fracture strength of casting Al7%Si-Mg alloy. Mater Sci Eng A 173:261–266

Wachter WJ (1955) Written discussion on “influence of vibration on fluidity and filling investment casting on aluminium”. AFS Trans 63:686

Cabeza, Gibiat V, Negreira C (2003) Observation of height localized structures in Faraday experiment with height dissipative fluids. Physica A 327:34–38

Campbell J (2004) Casting practice the 10 rules. Butterworth Heinemann, Oxford

British standard (2000) BSEN 10002: part 1

Campbell J (2003) Casting, 2nd edn. Elsevier, Oxford

Backerud L, Chai G, Tamminen J (1990) Solidification characteristic of aluminum alloys: foundry alloys, vol 2. American Foundry Society, Schaumburg

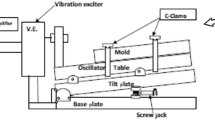

Karem WA, Green N, Al-Raheem KF (2012) Vibration assisted filling capability in thin wall investment casting. Int J Eng Sci Technol 61(9–12):873–877

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Abdul-Karem, W., Green, N., Al-Raheem, K.F. et al. Effect of vibration after filling on mechanical reliability in thin wall investment casting with fillability filling regime—part 1. Int J Adv Manuf Technol 67, 2075–2082 (2013). https://doi.org/10.1007/s00170-012-4632-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4632-z