Abstract

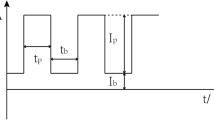

Based on 0Cr18Ni9Ti austenitic stainless steel plate (h = 6 mm), a study on arc behavior by ultrasonic frequency pulse gas tungsten arc welding (GTAW) process has been carried out. The results show that with the increasing pulse frequency, an obvious pinch effect of arc plasma has been detected and also the increment of arc voltage, stiffness, and force. Then, the method, combining weld appearance and numerical simulation, has been adapted for weld behavior on the basis of arc behavior by ultrasonic frequency pulse GTAW process. As a result of arc shrinkage, the root radius of arc decreased, which caused narrower weld bead. The larger arc force led to more depression of pool surface that made the downward heat source and external force point, which had been important to increasing weld penetration. Meanwhile, the mobility of molten pool was enhanced by weld behavior compared with conventional GTAW process.

Similar content being viewed by others

References

Qi BJ, Xu HY, Zhang W (2009) Microstructure and property analysis of 0Cr18Ni9Ti joints welded by ultra-sonic pulse tungsten-inert-gas welding technology. J Beihang Univ 35(2):132–133

Lin ML, Eagar TW (1985) Influence of arc pressure on weld pool geometry. Weld J 64(6):162–169

Kou S, Wang YH (1986) Weld pool convention and its effect. Weld J 65(3):63–70

Oreper GM, Szekyly J (1984) Heat and fluid flow phenomena in weld pools. J Fluid Mech 147:53–79

Kim WH, Fan HG, Na SJ (1997) Effect of various driving forces on heat and mass transfer in arc welding. Numer Heat Transf A: Appli 32(6):633–652

Jamshidi Aval H, Farzadi A, Serajzadeh S, Kokabi AH (2009) Theoretical and experimental study of microstructures and weld pool geometry during GTAW of 304 stainless steel. Int J Adv Manuf Technol 42:1043–1051

Farzadi A, Serajzadeh S, Kokabi AH (2008) Modeling of heat transfer and fluid flow during gas tungsten arc welding of commercial pure aluminum. Int J Adv Manuf Technol 38:258–267

Giridharan PK, Murugan N (2009) Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets. Int J Adv Manuf Technol 40:478–489

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) A mathematical model to predict impact toughness of pulsed-current gas tungsten arc-welded titanium alloy. Int J Adv Manuf Technol 35:852–858

Zhao JR, Sun D, Hu SS (1992) Arc behavior of high frequency pulse TIG welding arc. Trans China Weld Inst 13(1):59–66

Amin M (1983) Pulse current parameters for arc stability and controlled metal transfer in arc welding. Metal Constr 15:272–278

Zacharia T, David SA (1989) Weld pool development during GTA and laser beam welding of type 304 stainless steel, Part I-Theoretical analysis. Weld J 68(12):499–509

Cook GE, El-deam H, Eassa EH (1985) The effect of high-frequency pulsing of a welding arc. IEEE Trans Ind Applics 1A-21(5):1294–1299

Ghosh PK, Dorn L, Hübner M, Goyal VK (2007) Arc characteristics and behavior of metal transfer in pulsed current GMA welding of aluminum alloy. J Mater Process Technol 194:163–175

Jin O, Yoshisa A, Masayasu N, Mitsuo K, Onuma A, Funamoto T (2002) Development of a new high-frequency, high-peak current power source for high constricted arc formation. Japanese J Appl Phys 41:5821–5826

K Ando, M Hasegawa. Welding arc phenomena [M]. Beijing China Machine, 1985:249-250(in Chinese)

Choo RTC, Szekely J (1991) The effect of gas shear stress on Maragoni flows in arc welding. Weld J 70(9):223s–233s

Kumar A, DebRoy T (2003) Calculation of three-dimensional electromagnetic force field during arc welding. J Appl Phys 94(2):1267–1277

Chen SJ, Zhang BL, Yin SY, Wu HR (2006) Effects on aluminum-alloy TIG welding quality of double pulse modulated variable polarity waveform. Electr Weld Mach 36(2):7–14

Ge ZX, Chen HM, Ge Y (2004) Affection of arc-weld inversion power’s frequency on weld grain’s thinning. Hot Working Technol 7:47–48

Balasubramanian V, Ravisankar V, Madhusudhan Reddy G (2008) Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int J Adv Manuf Technol 36:254–262

Cong BQ, Qi BJ, Zhou XG (2009) TIG arc behavior of ultra fast-convert high-frequency variable polarity square wave. Trans China Weld Inst 6:87–90

Yang MX, Qi BJ, Cong BQ (2012) Fast-convert ultrasonic frequency pulse GTAW arc behavior. J Beijing Univ Aeronaut Astronaut 38(4):468–472

M.X. Yang, B.J. Qi, B.Q. Cong, W. Li. The influence of pulse current parameters on arc behavior by austenite stainless steel. Transactions of the China Welding Institution (in press).

Wu CS (1998) Numerical simulation of TIG weld pool behavior under the action of pulsed current. Acta Metallurgica Sinica 34(4):416–422

Cao ZN, Wu CS (1996) Mathematical modeling of TIG molten pool with full penetration. Trans China Weld Inst 17(1):62–70

C.S. Wu. Welding heat process and pool geometry [M]. Beijing China Machine, 2008 : 102–104 (in Chinese)

Qi BJ, Yang MX, Cong BQ, Li W (2012) Study on fast-convert ultrasonic frequency pulse TIG welding arc characteristic. Mater Sci Forum 704–705:745–751

Jia CS, Xiao KM, Yin XQ (1994) The plasmas flow force of welding arc. J XI’AN Jiaotong Univ 28(1):23–28, in Chinese

Atthey DR (1980) A mathematical model for fluid flow in a weld pool at high currents. J Fluid Mech 98(4):787–801

Oreper GM, Eagar TW (1983) Convection in arc weld pools. Weld J 62(11):307s–312s

Tsai MC, Kou S (1990) Electromagnetic force induced convection in weld pool with a free surface: a model is developed to predict heat transfer, fluid flow and pool shape in GTAW. Weld J 69(6):241s–246s

Z.N. Li. Research on the heat transfer and fluid flow in the laser-plasma hybrid welding [D]. Tsinghua University, 2007:44–46.

Kou S, Wang YH (1986) Computer simulation of convection in moving arc weld pools. Metall Trans A 11(17A):2271–2277

Heiple CR, Roper JR, Stagner RT, Aden RJ (1983) Surface active element effect on the shape of GTA, laser and electron-beam welds. Weld J 3:72s–77s

Oreper GM, Szekely J (1984) A comprehensive representation of transient weld pool development in spot welding operations. Weld J 147:53–79

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, B.J., Yang, M.X., Cong, B.Q. et al. The effect of arc behavior on weld geometry by high-frequency pulse GTAW process with 0Cr18Ni9Ti stainless steel. Int J Adv Manuf Technol 66, 1545–1553 (2013). https://doi.org/10.1007/s00170-012-4438-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4438-z