Abstract

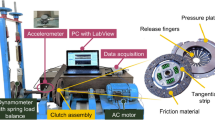

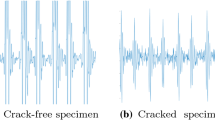

In this paper, we describe a condition classification technique designed to detect fault occurrence in an automotive light assembly during endurance testing. Inputs to the classifier are features extracted from vibration measurement data. They contain time domain parameters and frequency band energy parameters calculated using wavelet packet transforms. A support vector machine with Gaussian radial basis function kernel is designed for multiclass classification. A multiplex parameter estimation is achieved by searching for a minimum bound of the support vector count to achieve structural risk minimization. Through experiments, we show that the combination of effective feature extraction and classification with good generalization capability allows the proposed condition-monitoring system to be accurate and reliable. Additionally, acoustic signals known to have low signal to noise ratio are used as tests. We show that with the proposed methodology, acoustic signals can be used with increased sensitivity and accuracy for condition-monitoring purposes.

Similar content being viewed by others

References

Society of Automotive Engineers (2004) Test methods and equipment for lighting devices and components. SAE Specification J575, originally issued May 1942, revised Oct 2004

Mathew J (1987) Machine condition monitoring using vibration analysis. J Aust Acous Soc 15(1):7–13

Kershaw RJ (1986) Machine diagnostics with combined vibration analysis techniques. Proceedings of the 41th Meeting of the Mechanical Failures Prevention Group. pp 160–168

Asibu EK, Emel E (1987) Linear discriminant function analysis of acoustic emission signals for cutting tool monitoring. Mech Syst Signal Process 1(4):333–347

Ciocan RC, Ido N (2002) Method of early failure detection for elastic diaphragms based on frequency analysis of the acoustic signal. IEEE Trans Ultrason Ferroelectr Freq Control 49(8):1025–1028

Howard I (1994) A review of rolling element bearing vibration detection, diagnosis, and prognosis. Defense Sci. Technol. Org., Canberra, Australia, Tech. Rep. 0013

Akansu AN, Haddand RA (1992) Multiresolution signal decomposition: transform, subbands, and wavelets. Academic Press, San Diego, TK5102.5.A414

Torrence C, Compo GP (1998) A practical guide to wavelet analysis. Bull Am Meteorol Soc 79:61–78

Mertins A (1999) Signal analysis: wavelets, filter banks, time-frequency transform and applications. ISBN 0-471-98626-7, Wiley, pp 265–298

Vapnik V (1998) Statistical learning theory. Wiley, New York

Vapnik V (1999) The nature of statistical learning theory, 2nd edn. Springer, New York. ISBN 0-387-98780-0

Vapnik V, Chervonenkis A (1974) Theory of pattern recognition. Nauka, Moscow

Widodo A, Yang BS (2007) Support vector machine in machine condition monitoring and fault diagnosis. Mech Syst Signal Process 21(6):2560–2574

Chapelle O, Vpanik V, Bousquet O, Mukherjee S (2002) Choosing multiple parameters for support vector machines. Mach Learn 46:131–159

Sun Q, Tang Y, Lu WY, Ji Y (2005) Feature extraction with discrete wavelet transform for drill wear monitoring. J Vib Control 11(11):1375–1396

Xu CW, Liu Z, Luo WC (2009) A frequency band energy analysis of vibration signals for tool condition monitoring. Meas Technol Mechatron Autom 1:385–388, ICMTMA’09

Cortes C, Vapnik V (1995) Support vector networks. Mach Learn 20(3):273–297

Hsu C-W, Lin C-J (2002) A comparison of methods for multiclass support vector machines. IEEE Trans Neural Netw 13(2):415–425

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, W., Sun, Q. & Mechefske, C.K. Condition monitoring for the endurance test of automotive light assemblies. Int J Adv Manuf Technol 66, 1087–1095 (2013). https://doi.org/10.1007/s00170-012-4391-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4391-x