Abstract

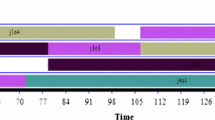

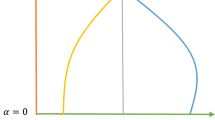

This paper develops a method for solving a multi-objective flow shop scheduling in a fuzzy environment where processing times are fuzzy numbers. The objective functions are designed to simultaneously minimize the makespan (completion time), the mean flow time, and the machine idle time. For each objective function, a fuzzy subset in the decision space whose membership function represents the balance between feasibility degree of constraints and satisfaction degree of the goal is defined. Then, technique for order preference by similarity to an ideal solution (TOPSIS) method finds the nondominated solution in a multiple objective state. The TOPSIS method and the interactive resolution method are integrated in the proposed method to solve the multi-objective flow shop scheduling problem. One of the new contributions of this research is combining these two methods in solving this problem. The proposed algorithm provides a way to find a crisp solution for the fuzzy flow shop scheduling in a multi-objective state. Also, the proposed method yields a reasonable solution that represents the balance between the feasibility of a decision vector and the optimality for an objective function by the interactive participation of the decision maker in all steps of decision process. Application of the proposed method to flow shop scheduling is shown with two numerical examples. The results show that the algorithm could be applied for determining the most preferable sequence by finding a nondominated solution for different degrees of satisfaction of constraints, and with regard to objective value, where processing time is fuzzy.

Similar content being viewed by others

References

Javadi B, Saidi-Mehrabad M, Haji A, Mahdavi I, Jolai F, Mahdavi-miri N (2008) No-wait flow shop scheduling using fuzzy multi-objective linear programming. J Franklin Inst 345:452–467

Allouche MA, Aouni B, Martel J, Loukil T, Reba A (2009) Solving multi-criteria scheduling flow shop problem through compromise programming and satisfaction functions. Eur J Oper Res 192:460–467

Seda M (2008) Mathematical models of flow shop and job shop scheduling problems. Int J Appl Math Comput Sci 4:241–246

Pan Q, Tasgetiren MF, Suganthan PN, Chua TJ (2010) A discrete artificial bee colony algorithm for the lot-straming flow shop scheduling problem. Inf Sci 181(12):2455–2468

Pesch E, Sterna M (2009) Late work minimization in flow shops by a genetic algorithm. Comput Ind Eng 57:1202–1209

Wang L, Pan Q, Suganthan PN, Wang W, Wang Y (2010) A novel hybrid discrete ifferential evolution algorithm for blocking flow shop scheduling problems. Comput Oper Res 37:509–520

Liu B, Wang L, Jin Y (2008) An effective hybrid PSO-based algorithm for flow shop scheduling with limited buffers. Comput Oper Res 35:2791–2806

Johnson SM (1954) Optimal two and three stage production schedules with set-up time included. Nav Res Logist Q 1:61–68

Moursli O, Pochet Y (2000) A branch-and-bound algorithm for the hybrid flow shop. Int J Prod Econ 64:113–125

Lian Z, Gu X, Jiao B (2006) A similar particle swarm optimization algorithm for permutation flow shop scheduling to minimize makespan. Appl Math Comput 175:773–785

Liu B, Wang L, Jin Y (2007) An effective hybrid particle swarm optimization for no-wait flow shop scheduling. Int J Adv Manuf Technol 31:1001–1011

Noorul Haq A, Radha Ramanan T, Shashikant KS, Sridharan R (2010) A hybrid neural network-genetic algorithm approach for permutation flow shop scheduling. Int J Prod Res 48(14):4217–4231

Yagmahan B, Yenisey MM (2010) A multi-objective ant colony system algorithm for flow shop scheduling problem. Expert Syst Appl 37:1361–1368

Toktas B, Azizoglu M, Koksalan SK (2004) Two-machine flow shop scheduling with two criteria: maximum earliness and makespan. Eur J Oper Res 157:286–295

Gupta JND, Neppall VR, Werner F (2001) Minimizing total flow time in a two-machine flow-shop problem with minimum makespan. Int J Prod Econ 69:323–338

Ponnambalam SG, Jagannathan H, Kataria M (2004) A TSP-GA multi-objective algorithm for flow-shop scheduling. Int J Adv Manuf Technol 23:909–915

Cohn A, Kurnaz S, Guan Y, Jiang Y (2010) Trading off between makespan and customer responsiveness in flow shop sequencing. Int J Prod Res 48(22):6777–6797

Chandra P, Mehta P, Tirupati D (2009) Permutation flow shop scheduling with earliness and tardiness penalties. Int J Prod Res 47(20):5591–5610

Razmi J, Tavakoli Moghadam R, Saffari M (2009) A mathematical model for a flow shop scheduling problem with fuzzy processing times. J Ind Eng 3:39–44

Ishibuchi H, Yamamoto N, Misaki S, Tanaka H (1994) Local search algorithms for flow shop scheduling with fuzzy due-dates. Int J Prod Econ 33:53–66

Murata T, Gen M, Ishibuchi H (1998) Multi-objective scheduling with fuzzy due-date. Comput Ind Eng 35:439–442

Jimenez M, Arenas M, Bilbao A, Rodriguez MV (2005) Linear programming with fuzzy parameters: an interactive method resolution. Eur J Oper 177(3):1599–1609

Lei D (2010) A genetic algorithm for flexible job shop scheduling with fuzzy processing time. Int J Prod Res 48(10):2995–3013

Lei D (2010) Solving fuzzy job shop scheduling problems using random key genetic algorithm. Int J Adv Manuf Technol 49:253–262

Mok PY, Kwong CK, Wong WK (2007) Optimisation of fault-tolerant fabric-cutting schedules using genetic algorithms and fuzzy set theory. Eur J Oper Res 177:1876–1893

Hu Y, Yin M, Li X (2011) A novel objective function for job-shop scheduling problem with fuzzy processing time and fuzzy due date using differential evolution algorithm. Int J Adv Manuf Technol 56:1125–1138

Guo ZX, Wong WK, Leung SYS, Fan JT, Chan SF (2008) Genetic optimization of order scheduling with multiple uncertainties. Expert Syst Appl 35(4):1788–1801

Wang Y, Lee H (2007) Generalizing TOPSIS for fuzzy multiple-criteria group decision-making. Comput Math Appl 53:1762–1772

Abo-Sinna MA, Abou-El-Enien THM (2006) An interactive algorithm for large scale multiple objective programming problems with fuzzy parameters through TOPSIS approach. Appl Math Comput 177:515–527

Sha DY, Lin H (2009) A particle swarm optimization for multi-objective flow shop scheduling. Int J Adv Manuf Technol 45:749–758

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakhaeinejad, M., Nahavandi, N. An interactive algorithm for multi-objective flow shop scheduling with fuzzy processing time through resolution method and TOPSIS. Int J Adv Manuf Technol 66, 1047–1064 (2013). https://doi.org/10.1007/s00170-012-4388-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4388-5