Abstract

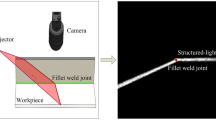

Traditionally, automated quality inspection of welding tasks relies on nonvisual information and is mainly done off-line. In this work, we introduce an image acquisition system which is capable of monitoring the welding process on-line, resulting in high-quality image information during an ongoing welding process. We show how to further exploit this image information by automatically tracking the weld seam position in the image, even under heavy smoke and gas disturbances. We exploit the high information redundancy between subsequent frames given by large overlap to generate a seamless image of the entire weld seam and effectively suppress adverse optical effects caused by, e.g., smoke and sparks.

Similar content being viewed by others

References

Bay H, Tuytelaars T, Gool LV (2006) Surf: speeded up robust features. In: European Conference on Computer Vision, pp 404–417

Bibby C, Reid I (2008) Robust real-time visual tracking using pixel-wise posteriors. In: European Conference on Computer Vision, pp 831–844

Bouguet JY (2000) Pyramidal Implementation of the Lucas Kanade Feature Tracker: Description of the algorithm. Intel Corporation, Microprocessor Research Labs

Burt PJ, Adelson EH (1983) The laplacian pyramid as a compact image code. IEEE T Commun 31(4):532–540

Fennander H, Kyrki V, Fellman A, Salminen A, Kaelviaeinen H (2007) Visual measurement and tracking in laser hybrid welding. Mach Vision Appl 20(2):103–118

Fischler MA, Bolles RC (1981) Random sample consensus: a paradigm for model fitting with applications to image analysis and automated cartography. Comm of the ACM 24(6):381–395

Gower J (1975) Generalized procrustes analysis. Psychometrika 40(1):33–51

Grabner H, Grabner M, Bischof H (2006) Real-time tracking via on-line boosting. In: Mike Chantler et al. (eds) Proceedings of British machine vision conference. Edinburg

He K, Sun J, Tang X (2009) Single image haze removal using dark channel prior. In: Conference on Computer Vision and Pattern Recognition, pp 1956–1963

Heber M, Reinbacher C, Ruether M, Bischof H (2011) Vision-based quality inspection in robotic welding. In: Proceedings of 35th Workshop of the Austrian Association for Pattern Recognition (AAPR/OAGM)

Ma H, Wei S, Sheng Z, Lin T, Chen S (2009) Robot welding seam tracking method based on passive vision for thin plate closed-gap butt welding. Int J Adv Manuf Technol 48(9–12):945–953

Matthews I, Ishikawa T, Baker S (2004) The template update problem. IEEE Transactions on Pattern Analysis and Machine Intelligence 26(6):810–815

Mertens T, Kautz J, Van Reeth F (2007) Exposure fusion. In: Proceedings of Pacific Conference on Computer Graphics Applications

Schreiber D, Cambrini L, Biber J, Sardy B (2008) Online visual quality inspection for weld seams. Int J Adv Manuf Technol 42(5–6):497–504

Shi YH, Kim JT, Na SJ (2005) Signal patterns of high speed rotational arc sensor for gas metal arc welding. In: Proceedings on Sensors for Industry Conference, Houston, TX 8-10. pp 9–14

Wang JF, Chen B, Chen HB, Chen SB (2009) Analysis of arc sound characteristics for gas tungsten argon welding. Sens Rev 29(3):240–249

Welch G, Bishop G (1995) An introduction to the kalman filter. Tech. rep., Department of Computer Science, University of North Carolina at Chapel Hill

Xu P, Xu G, Tang X, Yao S (2007) A visual seam tracking system for robotic arc welding. Int J Adv Manuf Technol 37(1–2):70–75

Yan Z, Xu D (2008) Visual tracking system for the welding of narrow butt seams in container manufacture. In: Proceedings of the UKACC International Conference on Control 2008

Zhang T, Li K, Dai S, Xiao S, Huang H (2009) Research on seam tracking controller of mobile welding robot. In: Proceedings on Automation and Logistics (ICAL09), pp 2011–2014

Zhao W (2006) Flexible image blending for image mosaicing with reduced artifacts. Int J Pattern Recogn Artif Intell (IJPRAI) 20(4):609–628

Author information

Authors and Affiliations

Corresponding author

Additional information

This study has been conducted within the COMET K-Project “Embedded Computer Vision” (ECV)

Rights and permissions

About this article

Cite this article

Heber, M., Lenz, M., Rüther, M. et al. Weld seam tracking and panorama image generation for on-line quality assurance. Int J Adv Manuf Technol 65, 1371–1382 (2013). https://doi.org/10.1007/s00170-012-4263-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4263-4