Abstract

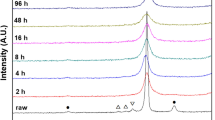

Mechanical alloying through high-energy ball milling was used in the production of Ni–Fe alloy powders from elemental Ni and Fe powders of average particle size 80 and 25 μm, respectively. High-energy planetary ball milling at room temperature was performed for various time durations ranging between 2 and 100 h. SPS apparatus was used for sintering of powder particles. Density of all specimens was reported and a maximum densification of 99 % was achieved in 50 wt.% Ni–Fe milled for 16 h prior to spark plasma sintering at 1,223 K.

Similar content being viewed by others

References

Chryssolouris G, Stavropoulos P, Tsoukantas G, Salonitis K, Stournaras A (2004) Nanomanufacturing processes: a critical review. Int J Mater Prod Technol 21(4):331–348

Barrett WF, Brown W, Hadfield RA (1902) Researches on the electrical conductivity and magnetic properties of upwards of one hundred different alloys of iron. Inst Elec Eng J 31:674–729

Miura H, Isa S, Omuro K (1990) Preparation of iron–nickel based metal–metalloid amorphous powders by mechanical alloying. J Non-Cryst Solids 117–118(Part 2):741–744

Ivanov E (1992) Preparation of Cu x Hg1 − x solid solutions by mechanical alloying. Mater Sci Forum 88–90:475–480

Yavari AR, Desré PJ, Benameur T (1992) Mechanically driven alloying of immiscible elements. Phys Rev Lett 68(14):2235–2238

Niihara K (1991) New design concept of structural ceramics―ceramic nanocomposites. J Ceram Soc Jpn 99(10):974–982

Perera DS, Tokita M, Moricca S (1998) Comparative study of fabrication of Si3N4/SiC composites by spark plasma sintering and hot isostatic pressing. J Eur Ceram Soc 18(4):401–404

Gao L, Wang HZ, Hong JS, Miyamoto H, Miyamoto K, Nishikawa Y, Torre SDDL (1999) Mechanical properties and microstructure of nano-SiC–Al2O3 composites densified by spark plasma sintering. J Eur Ceram Soc 19(5):609–613

Zhang HW, Gopalan R, Mukai T, Hono K (2005) Fabrication of bulk nanocrystalline Fe–C alloy by spark plasma sintering of mechanically milled powder. Scr Mater 53(7):863–868

Gopalan R, Kündig AA, Ohnuma M, Kishimoto S, Hono K (2005) Mechanically milled and spark plasma sintered FePt-based bulk magnets with high coercivity. Scr Mater 52(8):761–765

Biswas K, Mukhopadhyay A, Basu B, Chattopadhyay K (2007) Densification and microstructure development in spark plasma sintered WC–6 wt % ZrO2 nanocomposites. J Mater Res 22(6):1491–1501

Kar S, Sarma ES, Somu VB, Kishore NK, Srinivas V (2008) Evaluation of different consolidation methods for nano-materials. Indian J Eng Mater Sci 15(4):343–346

Scherrer P (1918) Göttinger Nachrichten Gesell 2:98

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1(1):22–31

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashokkumar, T., Rajadurai, A., Gouthama et al. A study of densification and on factors affecting the density of Ni x –Fe100 − x nanopowders prepared by mechanical alloying and sintered by spark plasma. Int J Adv Manuf Technol 65, 1201–1213 (2013). https://doi.org/10.1007/s00170-012-4247-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4247-4