Abstract

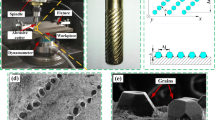

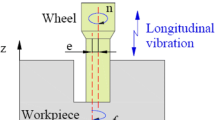

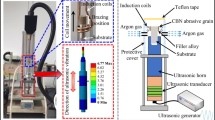

During rotary ultrasonic grinding process, working performance of ultrasonic vibration tools varies according to the bonding patterns between diamond grit and bond. In order to understand the influence of ultrasonic vibration tools on working performance, bonding patterns and bonding strength of ceramic-bonded, iron-bonded, and bronze-bonded tools were investigated. Influence of bonding strength on cutting force, tool wear, surface quality, and edge breakout were studied, coupled with the characteristics of ultrasonic vibration tools. The results show that cutting force in Z axis and tool wear reduce with the increase of bonding strength while the surface quality and edge breakout become worse.

Similar content being viewed by others

References

Li ZC, Jiao Y, Deines TW, Pei ZJ, Treadwell C (2005) Rotary ultrasonic machining of ceramic matrix composites: feasibility study and designed experiments. Int J Mach Tool Manuf 45:1402–1411. doi:10.1016/j.ijmachtools.2005.01.034

Ya G, Qin HW, Yang SC, Xu YW (2002) Analysis of the rotary ultrasonic machining mechanism. J Mater Process Technol 129:182–185. doi:10.1016/S0924-0136(02)00638-6

Kazantsev VF, Rozenberg LD (1965) The mechanism of ultrasonic cutting. Ultrasonic 13(4):166–174. doi:10.1016/0041-624X(65)90165-4

Gong H, Fang FZ, Hu X (2010) Kinematic view of tool life in rotary ultrasonic side milling of hard and brittle materials. Int J Mach Tool Manuf 50(3):303–307

Liu JH, Pei ZJ, Fisher GR (2007) Grinding wheels for manufacturing of silicon wafers: a literature review. Int J Mach Tool Manuf 47(1):1–13. doi:10.1016/j.ijmachtools.2006.02.003

Drozda TJ, Wick C (1983) Tool and manufacturing engineers handbook. Society of Manufacturing Engineers, Michigan

Jackson MJ (2002) Fracture dominated wear of perfectly sharp abrasive grinding wheels. J Eng Tribol 218(3):225–235. doi:10.1243/135065004132339

Zhengxin L, Tui Z, Xuefeng Y, Xiang-rong DENG (2011) Research on diamond holding strength of ceramic matrix. Adv Mater Res 177:657–659. doi:10.4028/www-scientific.net/AMR177.657

Hou Y, Zou W, Xiao F (2008) Effect of sintering manner on performance of vitrified bond diamond tools. Diam Abras Eng 3:39–42

Ning C, Xiao L, Wang J (2011) Performance evaluation for resin bond of coated diamond tools. Superhard Mater Eng 23(1):13–17

Bridwell HC, Appl FC (1974) A study of “free cutting” with diamond saws. Ind Diam Rev 2:51–53

Miyazaki M, Onose H, Iida N, Kazama H (2003) Determination of residual double bonds in resin–dentin interface by Raman spectroscopy. Dent Mater 19(3):245–251. doi:10.1016/S0109-5641(02)00039-8

Fan F, Tang W, Liu S, Hei L, Li C, Chen G, Lu F (2006) An effort to enhance adhesion of diamond coatings to cemented carbide substrates by introducing Si onto the interface. Surf Coat Technol 200(24):6727–6732. doi:10.1016/j.surfcoat.2005.10.001

Wang PF, Li ZhH, Li J, Zhu YM (2009) Effect of ZnO on the interfacial bonding between Na2O–B2O3–SiO2 vitrified bond and diamond. Solid State Sci 11:1427–1432. doi:10.1016/j.solidstatesciences.2009.04.026

Nonogawa T, Kondo T (2005) Segmental type grinding wheel. US Patent 6846233

Jackson MJ, Mills B (2001) Vitrification heat treatment and dissolution of quartz in grinding wheel bonding systems. Br Ceram Trans 100(1):1–9. doi:10.1179/0967978 01681116 DOI:dx.doi.org

Xie J, Zhou RM, Xu J, Zhong YG (2010) Form-truing error compensation of diamond grinding wheel in CNC envelope grinding of free-form surface. Int J Adv Manuf Technol 48:905–912. doi:10.1007/s00170-009-2338-7

Li Z-X, Yang X-F, Deng X-R, Xiao C-J (2010) Research on diamond holding strength of ceramic matrix. Superhard Mater Eng 22(5):5–7

Dai Q, Xu X, Wang Y (2002) Measures used to improve binding of diamond to matrix and binding mechanisms. Mater Sci Eng 20(3):465–468

Chern G-L (2005) Study on a new turning method to simulate orthogonal cutting and to verify an edge breakout model. Int J Adv Manuf Technol 26:965–969. doi:10.1007/s001700 04-2087-6

Ren J, Kang R, Shi X (1999) Grinding of difficult-to-cut materials. National Defense Industry Press, Beijing

Liu Y, Zhao H, Jing J (2011) Research on material removal rate in rotary ultrasonic grinding machining. IJ Nanomafacturing 7(2):158–168. doi:10.1504/IJNM.2011. 040721

Zhang W, Subhash G (2001) An elastic-plastic-cracking model for finite element analysis of indention cracking in brittle materials. Int J Solids Struct 38:5893–5913. doi:10.1016/S0020-7683(00)00406-6

Zeng WM, Li ZC, Pei ZJ (2005) Experimental observation of tool wear in rotary ultrasonic machining of advanced ceramics. Mach Tool Manuf 45:1468–1473. doi:10.1016/j.ijmachtools.2005.01.031

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Zhao, H., Jing, J. et al. Investigation on the bonding strength patterns of ultrasonic vibration tools and influence on working performance during rotary ultrasonic grinding. Int J Adv Manuf Technol 65, 533–541 (2013). https://doi.org/10.1007/s00170-012-4192-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4192-2