Abstract

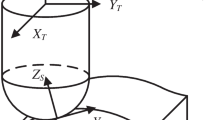

This paper presents a flexible model for estimating the form error in three-axis ball-end milling of sculptured surface with z-level contouring tool path. At an interval of feed per tooth, the whole process of sculptured surface machining is treated as a combination of sequential small inclined surface milling. For ball-end milling of the inclined surface with z-level contouring tool path, at surface generation position, an analytical model is proposed to identify the feedback effect of tool deflection on cutting edge engagement. The deflection-dependent cutting edge engagement is determined by using an iterative procedure. And ultimately, the form error is obtained from the balanced tool deflection and associated surface inclination angle. In a validation experiment, the estimated form errors are compared with both the measurements and the predictions of a rigid model. It is shown that the proposed flexible model gives significant better predictions of the form error than rigid model. Good agreement between the predicted and measured form errors is demonstrated for the ball-end milling of sculptured surface with z-level contouring tool path.

Similar content being viewed by others

References

Kline WA, DeVor RE, Shareef IA (1982) The prediction of surface accuracy in end milling. ASME J Eng Ind 104(3):272–278

López de Lacalle LN, Lamikiz A, Sánchez JA, Salgado MA (2004) Effects of tool deflection in the high-speed milling of inclined surfaces. Int J Adv Manuf Technol 24(9):621–631

Larue A, Anselmetti B (2003) Deviation of a machined surface in flank milling. Int J Mach Tool Manufact 43(2):129–138

Rao VS, Rao PVM (2006) Effect of workpiece curvature on cutting forces and surface error in peripheral milling. Proc IMechE Part B: J Eng Manuf 220(9):1399–1407

Wang M-Y, Chang H-Y (2003) A simulation shape error for end milling AL6061-T6. Int J Adv Manuf Technol 22(9):689–696

Kim GM, Kim BH, Chu CN (2003) Estimation of cutter deflection and form error in ball-end milling processes. Int J Mach Tools Manuf 43(9):917–924

Smaoui M, Bouaziz Z, Zghal A, Dessein G, Baili M (2011) Simulation of the deflected cutting tool trajectory in complex surface milling. Int J Adv Manuf Tech 56(5):463–474

Ryu S (2012) An analytical expression for end milling forces and tool deflection using Fourier series. Int J Adv Manuf Tech 59(1):37–46

Sutherland JW, DeVor RE (1986) An improved method for cutting force and surface error prediction in flexible end milling systems. ASME J Eng Ind 108(4):269–279

Lim EM, Menq C-H (1995) The prediction of dimensional error for sculptured surface productions using the ball-end milling process. Part 2: surface generation model and experimental verification. Int J Mach Tools Manuf 35(8):1171–1185

Budak E, Altintas Y (1992) Flexible milling force model for improved surface error prediction. In Proc 1992 Engineering System Design and Analysis, Istanbul, Turkey, ASME 47–1 (89–94

Wan M, Zhang WH (2006) Calculations of chip thickness and cutting forces in flexible end milling. Int J Adv Manuf Technol 29(7):637–647

Budak E, Altintas Y (1995) Modeling and avoidance of static form errors in peripheral milling of plates. Int J Mach Tools Manuf 35(3):459–476

Wan M, Zhang WH (2006) Efficient algorithms for calculations of static form errors in peripheral milling. J Mater Process Technol 171(1):156–165

Ratchev S, Liu S, Huang W, Becker AA (2004) Milling error prediction and compensation in machining of low-rigidity parts. Int J Mach Tools Manuf 44(15):1629–1641

Bera TC, Desai KA, Rao PVM (2011) Error compensation in flexible end milling of tubular geometries. J Mater Process Tech 211(1):24–34

Wei ZC, Wang MJ, Zhu JN, Gu LY (2011) Cutting force prediction in ball end milling of sculptured surface with Z-level contouring tool path. Int J Mach Tool Manufact 51(5):428–432

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, Z.C., Wang, M.J., Cai, Y.J. et al. Form error estimation in ball-end milling of sculptured surface with z-level contouring tool path. Int J Adv Manuf Technol 65, 363–369 (2013). https://doi.org/10.1007/s00170-012-4175-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4175-3