Abstract

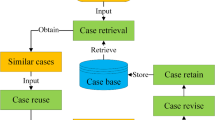

In this research paper, hard machining of two materials viz. AISI 52100 (bearing steel) and AISI D2 (tool steel) at a hardness of 55 HRC is addressed. Taguchi’s technique is used for the design of experiments. Eight different parameters are considered for the experimentation in order to perform comprehensive investigations on hard machining process. Case-based reasoning (CBR) model is developed for predicting the machining performance and its capability is evaluated by conducting validation experiments. The root mean squared error, mean absolute percentage error, and the correlation coefficient between the actual and the model-predicted values of surface roughness and tool life are evaluated to confirm the validity of the CBR model.

Similar content being viewed by others

References

Sharman A, Dewes RC, Aspinwall DK (2001) Tool life when high speed ball nose end milling Inconel 718. J Mater Process Tech 118:29–35

Yih-Fong T (2006) Parameter design optimization of computerized numerical control turning tool steels for high dimensional precision and accuracy. Mater Des 27:665–675

Wang J (2000) The effect of the multi-layer surface coating of carbide inserts on the cutting forces in turning operations. Int J Met Hard Mater 97:114–119

Errico DGE, Bugliosi S, Guglielmi E (1998) Tool-life reliability of cermet inserts in milling tests. J Mater Process Technol 77:337–343

Tae KW, Park JS, Kang S (2005) Effect of group IV elements on the cutting characteristics of Ti(C, N) cermet tools and reliability analysis. J Mater Process Technol 166(1):9–14

Whitney ED (1994) Ceramic cutting tool Materials, development and performance. Springer, New York, pp 213–215

Konyashin IY (1996) Chemical vapour deposition of thin coatings onto Al2O3 indexable cutting inserts. Surf CoatTechnol 85:131–137

Qian Li, Hossan MR (2007) Effect on cutting force in turning hardened tool steels with cubic boron nitride inserts. J Mater Process Technol 191:274–278

Paiva AP, Ferreira JR, Balestrassi PP (2007) A multivariate hybrid approach applied to AISI 52100 hardened steel turning optimization. J Mater Process Technol 189:26–35

Quiza R, Figueira L, Davim JP (2008) Comparing statistical models and artificial neural networks on predicting the tool wear in hard machining D2 AISI steel. Int J Adv Manuf Technol 37:641–648

Gupta D, Gopalakrishnan B (2010) Energy sensitive machining parameter optimization. Int J Ind Syst Eng 5(4):405–423

An S-H, Kim G-H, Kang Kyung-In (2007) A Case-Based reasoning cost estimating model using experience by analytic hierarchy process. Build Environ 42:2573–2579

Gaoliang P, Guangfeng C, Xinhua L (2010) Using CBR to develop a VR-based integrated system for machining fixture design. Assemb Autom 30(3):228–239

Cho Min-Ho, Kim D-W, Lee C-G, Heo E-Y, Ha J-W, Chen F (2009) Case-based impeller machining strategy support system. J Robot Comput Integrated Manuf 25(6):145–156

Cai-yan L, You-fa S (2010) A hierarchical case-based reasoning system for quality design. Appl Mech Mater 20–23:1015–1020

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xavior, A.M., Anouncia, M.S. Case-based reasoning (CBR) model for hard machining process. Int J Adv Manuf Technol 61, 1269–1275 (2012). https://doi.org/10.1007/s00170-012-4092-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4092-5