Abstract

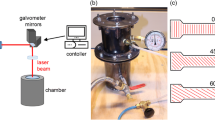

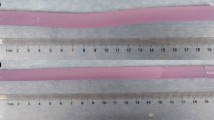

A finite element model was developed to simulate the influence of laser scan patterns (laser jump patterns, ratio of length to width and laser scan angle) on the temperature and stress distributions in the process of laser direct sintering ceramics. The effects of laser scan patterns on the stresses in the laser directly sintered ceramic samples were investigated by simulation. Different ceramic samples were prepared by the laser sintering process for the four-point bending strength measurement. The simulation results consist with the experimental ones. The results in the present research can be used to optimize process route for the laser direct sintering process and provide a guidance for selecting the laser processes parameters for high mechanical strength ceramic components.

Similar content being viewed by others

References

Hinczewski C, Corbel S, Chartier TJ (1998) Ceramic suspensions suitable for stereolithography. J Eur Ceram Soc 18:583–590

Zhou WZ, Li DC, Chen ZW (2011) Influence of ingredients and laser exposure on curing behaviors of aqueous ceramic suspensions in stereolithography. Int J Adv Manuf Technol 52:575–582

Bertrand PH, Bayle F, Combe C, Goeuriot P, Smurov I (2007) Ceramic components manufacturing by selective laser sintering. Appl Surf Sci 254:989–992

Mason MS, Huang T, Landers RG, Leu MC, Hilmas GE (2009) Aqueous-based extrusion of high solids loading ceramic pastes: process modeling and control. J Mater Proc Technol 209:2946–2957

Wang J, Shaw L (2005) Rheological and extrusion behavior of dental porcelain slurries for rapid prototyping applications. Mater Sci Eng A 397:314–321

Tian XY, Li DC (2010) Rapid manufacture of net-shape SiC components. Int J Adv Manuf Technol 46:579–587

Friedel T, Travitzky N, Niebling F, Scheffler M, Greil P (2005) Fabrication of polymer derived ceramic parts by selective laser curing. J Eur Ceram Soc 25:193–197

Wu HH, Li DC, Chen XJ, Sun B, Xu DY (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Technol 50:13–19

Günster J, Engler S, Heinrich JG (2003) Forming of complex shaped ceramic products via layer-wise slurry deposition (LSD). Bull EcerS 1:25–28

Gahler A, Heinrich JG, Günster J (2006) Direct laser sintering of Al2O3–SiO2 dental ceramic components by layer-wise slurry deposition. J Am Ceram Soc 89:3076–3080

Yen HC, Tang HH (2008) Developing a paving system for fabricating ultra-thin layers in ceramic laser rapid prototyping. Int J Adv Manuf Technol 36:280–287

Tian XY, Günster J, Melcher J, Li DC, Heinrich JG (2009) Process parameters analysis of direct laser sintering and post treatment of porcelain components using Taguchi's method. J Eur Ceram Soc 29:1903–1915

Yen HC, Tang HH (2012) Study on direct fabrication of ceramic shell mold with slurry-based ceramic laser fusion and ceramic laser sintering. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3664-0

Dingal S, Pradhan TR, Sarin Sundar JK, Roy Choudhury A, Roy SK (2008) The application of Taguchi's method in the experimental investigation of the laser sintering process. Int J Adv Manuf Technol 38:904–914

Tian XY, Sun B, Heinrich GJ, Li DC (2010) Stress relief mechanism in layer-wise laser directly sintered porcelain ceramics. Mater Sci Eng 527(7):1695–1703. doi:10.1016/j.msea.2009.10.058

Nickel AH, Barnett DM, Prinz FB (2001) Thermal stresses and deposition patterns in layered manufacturing. Mater Sci Eng A 317:59–64

Bugeda G, Cervera M, Lombera G (1999) Numerical predication of temperature and density distributions in selective laser sintering processes. Rapid Prototyp J 5:21–26

Williams J, Deckard CR (1998) Advances in modeling the effects of selected parameters on the SLS process. Rapid Prototyp J 4:99–100

Amon CH, Beuth JL, Weiss LE, Merz R, Prinz FB (1998) Shape deposition manufacturing with microcasting: processing, thermal and mechanical issues. J Manuf Sci Eng 120:656

Wang L, Felicelli SD, Craig JE (2009) Experimental and numerical study of the LENS rapid fabrication process. J Manuf Sci Eng 131:041019–041027

Dai K, Shaw L (2006) Parametric studies of multi-material laser densification. Mater Sci Eng, A 430:221–229

Dai K, Shaw L (2003) Finite-element analysis of effects of the laser-processed biomaterial component size on stresses and distortion. Metall Mater Trans A 34A:1133–1145

Dai K, Crocker JE, Shaw LL, Marcus HL (2003) Thermal modelling of selective area laser deposition (SALD) and SALD vapor infiltration of silicon carbide. Rapid prototyp J 9:231–239

Dai K, Shaw L (2005) Finite element analysis of the effect of volume shrinkage during laser densification. Acta Mater 53:4743–4754

Schneider SJ (1991) Engineered materials handbook. Vol. 4. Ceramics and glasses. ASM International, Materials Park, p 30

Touloukia YS, Ho CY (1970) Thermaophysical properties of matter. Vol. 12. Thermal expansion: nonmetallic solids. IFI/Plenum, New York, p 1369

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, X., Sun, B., Heinrich, J.G. et al. Scan pattern, stress and mechanical strength of laser directly sintered ceramics. Int J Adv Manuf Technol 64, 239–246 (2013). https://doi.org/10.1007/s00170-012-3994-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3994-6