Abstract

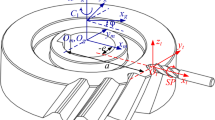

The present work is a continuation of the first part of the article and is devoted to the geometric calculation of shape parameters of the working surfaces of disk-shaver teeth for use in finishing cylindrical gears with an evolvent profile. A method has been proposed for determining the shape of the working surfaces in disk-shaver teeth during the recessed shaving of cylindrical gears with technologically modified teeth. In this case, the machined gear tooth surfaces are discretely specified, and consequently familiar analytical methods of tool profiling are unacceptable.

Similar content being viewed by others

References

Bebamzadeh A, Haukaas T (2008) Second-order sensitivities of inelastic finite-element response by direct differentiation. J Eng Mech 134:867–880. doi:10.1061/(ASCE)0733-9399(2008) 134:10(867

Cai CS, Wu WJ, Araujo M (2007) Cable vibration control with a TMD-MR Damper System. J Struct Eng 133:629–637. doi:10.1061/(ASCE)0733-9445(2007) 133:5(629

Joghataie A, Farrokh M (2008) Dynamic analysis of nonlinear frames by Prandtl neural networks. J Eng Mech 134:961–969. doi:10.1061/(ASCE)0733-9399(2008)134:11(961

Main JA, Jones NP (2007) Vibration of tensioned beams with intermediate damper. J Eng Mech 133:369–378. doi:10.1061/(ASCE)0733-9399(2007)133:4(369

Radzevich SP (1991) Shaping of complex surfaces on numerically controlled machine tools. Vishcha Shkola, Kiev

Radzevich SP (2003) Design of shaving cutter for plunge shaving a topologically modified involute pinion. ASME J Mechan Des 125:632–639. doi:10.1115/1.1588346

Radzevich SP (2005) Computation of parameters of a form grinding wheel for grinding of shaving cutter for plunge shaving of topologically modified involute pinion. ASME J Manuf Sci Eng 127:819–828. doi:10.1115/1.2037087

Radzevich SP (2005) A descriptive geometry-based solution to a geometric problem in rotary shaving of a shoulder pinion. ASME J Manuf SciEng 127:839–900. doi:10.3103/S1068798X09010195

Radzevich SP (2007) On satisfaction of the fifth necessary condition of proper part surface generation in design of plunge shaving cutter for finishing of precision involute gears. ASME J Mechan Des 129:969–980. doi:10.1115/1.2748452

Starr CM, Krauthammer T (2005) Cladding-structure interaction under impact loads. J Struct Eng 131:1178–1185. doi:10.1061/(ASCE)0733-9445(2005)131:8(1178

Young B, Chen J (2008) Design of cold-formed steel built-up closed sections with intermediate stiffeners. J Struct Eng 134:727–737. doi:10.1061/(ASCE)0733-9445(2008)134:5(727

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Radzevich, S.P., Kreheľ, R. Determination of the grinding wheel profile and its setup for use in finishing cylindrical gears with an evolvent profile. Int J Adv Manuf Technol 63, 875–879 (2012). https://doi.org/10.1007/s00170-012-3982-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3982-x