Abstract

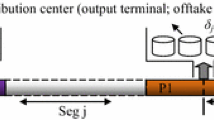

Pipelines are widely used in transport systems and public utilities and infrastructures. To produce their components, specially designed multi-positional machines are employed. Since the cost of the equipment used affects the cost of final pipelines, the design of such machines is an important financial issue. This paper presents such a design problem formulated as a combinatorial optimization problem. Two mathematical models and an efficient solution approach are suggested. Industrial examples are also considered in order to demonstrate the use of the method developed.

Similar content being viewed by others

References

Cafaro D, Cerdá J (2008) Dynamic scheduling of multiproduct pipelines with multiple delivery due dates. Comput Chem Eng 32(4–5):728–753

Orban-Mihalyko E, Lakatos B (2005) Sizing of pipeline capacities in processing systems under stochastic operation conditions. Comput Chem Eng 29(7):1599–1612

Chebouba A, Yalaoui F, Smati A, Amodeo L, Younsi K, Tairi A (2009) Optimization of natural gas pipeline transportation using ant colony optimization. Comput Oper Res 36(6):1916–1923

Usubamatov R, Abdulmuin M, Nor A, Murad M (2008) Productivity rate of rotor-type automated lines and optimization of their structure. Proc Inst Mech Eng B J Eng Manuf 222(11):1561–1566

Battini D, Faccio M, Ferrari E, Persona A, Sgarbossa F (2007) Design configuration for a mixed-model assembly system in case of low product demand. Int J Adv Manuf Technol 34(1):188–200

Dolgui A, Guschinsky N, Levin G (2009) Graph approach for optimal design of transfer machine with rotary table. Int J Prod Res 47(2):321–341

Wu B, Young G, Huang T (2000) Application of a two-level optimization process to conceptual structural design of a machine tool. Int J Mach Tools Manuf 40(6):783–794

Xu L, Li Z, Li S, Tang F (2005) A polychromatic sets approach to the conceptual design of machine tools. Int J Prod Res 43(12):2397–2421

Contini P, Tolio T (2004) Computer-aided set-up planning for machining centres configuration. Int J Prod Res 42(17):3473–3491

Koren Y, Heisel U, Jovane F, Moriwaki T, Pritchow G, Brussel HV, Ulsoy A (1999) Reconfigurable manufacturing systems. CIRP Ann 48(2):527–598

Mehrabi M, Ulsoy A, Koren Y (2000) Reconfigurable manufacturing systems: key to future manufacturing. J Intell Manuf 11:403–419

Mehrabi M, Ulsoy A, Koren Y, Heytler P (2002) Trends and perspectives in flexible and reconfigurable manufacturing systems. J Intell Manuf 13:135–146

Abdi M, Labib A (2003) A design strategy for reconfigurable manufacturing systems (RMSs) using analytical hierarchical process (AHP): a case study. Int J Prod Res 41(10):2273–2299

Youssef A, ElMaraghy H (2008) Availability consideration in the optimal selection of multiple-aspect RMS configurations. Int J Prod Res 46(21):5849–5882

Liu W, Liang M (2008) Multi-objective design optimization of reconfigurable machine tools: a modified fuzzy-Chebyshev programming approach. Int J Prod Res 46(6):1587–1618

Guschinskaya O, Dolgui A, Guschinsky N, Levin G (2007) A scheduling problem for multi-spindle head machines with a mobile table. Comput Oper Res 36(2):344–357

Guschinskaya O, Dolgui A (2009) A comprehensive comparative analysis of exact and heuristic methods for transfer line balancing problems. Int J Prod Econ 120(2):276–286

Essafi M, Delorme X, Dolgui A, Guschinskaya O (2010) A MIP approach for balancing transfer lines with complex industrial constraints. Comput Ind Eng 58(3):393–400

Guschinskaya O, Gurevsky E, Dolgui A, Eremeev A (2011) Metaheuristic approaches for the design of machining lines. Int J Adv Manuf Technol 55(1):11–22

Hitomi K (1996) Manufacturing systems engineering. Taylor & Francis. London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Battaïa, O., Dolgui, A., Guschinsky, N. et al. Optimal design of machines processing pipeline parts. Int J Adv Manuf Technol 63, 963–973 (2012). https://doi.org/10.1007/s00170-012-3981-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3981-y