Abstract

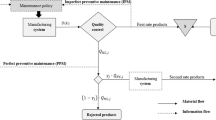

In this paper, a modified economic manufacturing quantity model under the imperfect product quality is developed. Taguchi’s quadratic quality loss function is integrated into the model to evaluate the product quality. The rework process is also imperfect; the reworked item can be one of the qualities: conforming, not usable and scraped, or needing rework again. The three-state Markovian infinite rework of imperfect products is developed and considered in the modified model. By solving the modified model, we can obtain the optimum combination of the production quantity, process mean, and the specification limits that lead to the maximized profit. A numerical example and sensitivity analysis of parameters of the model are provided for illustration.

Similar content being viewed by others

References

Taguchi G (1986) Introduction to quality engineering. Asian Productivity Organization, Tokyo

Springer CH (1951) A method of determining the most economic position of a process means. Ind Qual Control 8(1):36–39

Bettes DC (1962) Finding an optimal value to a fixed lower limit and an arbitrary upper limit. ApplStat 11:202–210

Hunter WG, Kartha CP (1977) Determining the most profitable target value for a production process. J Qual Technol 9(4):176–181

Al-Sultan KS, Pulak MFS (2000) Optimum target values for two machines in series with 100% inspection. Eur J Oper Res 120(1):181–189

Carlsson O (1989) Economic selection of a process level under acceptance sampling variables. Eng Costs Prod Econ 16(1):69–78

Boucher TO, Jafari MA (1991) The optimum target value for single filling operations with quality sampling plans. J Qual Technol 23(1):44–47

Carlsson O (1992) Quality selection of a two-dimensional process level under single acceptance sampling by variables. Int J Prod Econ 27(1):43–56

Liou MJ, Tseng ST, Lin TM (1994) The effects of inspection errors to the imperfect EMQ Model. IIE Trans 26(2):42–51

Rahim MA, Al-Sultan KS (2000) Joint determination of the optimum target mean and variance of a process. J Qual Maint Eng 6(3):192–199

Phillips DM, Cho BR (2000) A nonlinear model for determining the most economic process mean under a beta distribution. Int J Reliab Qual Saf Eng 7(1):61–74

Teeravaraprug J, Cho BR (2002) Designing the optimum process target for multiple quality characteristics. Int J Prod Res 40:37–54

Kim YJ, Cho BR (2003) Determining the optimum process mean for a skewed process. Int J Ind Eng—Theory Applic Pract 10:555–561

Duffuaa SO, Siddiqui AW (2003) Process targeting with multi-class screening and measurement error. Int J Prod Res 41(7):1373–1391

Teeravaraprug J (2005) Determining optimal process mean of two-market products. Int J Adv Manuf Technol 25(11–12):1248–1253

Lee MK, Kim SB, Kwon HM, Hong SH (2004) Economic selection of mean value for a filling process under quadratic quality loss. Int J Reliab Qual Saf Eng 11(1):81–90

Rahim MA, Tuffaha F (2004) Integrated model for determining the optimal initial settings of the process mean and optimal production run assuming quadratic loss functions. Int J Prod Res 42(16):3281–3300

Chen CH (2006) The optimum selection of imperfect quality economic manufacturing quantity and process mean by considering quadratic quality loss function. J Chin Inst Ind Eng 23:12–19

Chen CH, Chou CY (2006) Determining the optimum process parameters by asymmetric quality loss function. Matematika 22(2):129–135

Chen CH, Lai MT (2007) Determining the optimum process mean based on quadratic quality loss function and rectifying inspection plan. Eur J Oper Res 182(2):755–763

Chen CH, Kao HS (2009) The determination of optimum process mean and screening limits based on quality loss function. Expert Syst Appl 36(3):7332–7335, Part 2

Chen CH, Khoo MBC (2009) Optimum process mean and manufacturing quantity settings for serial production system under the quality loss and rectifying inspection plan. Comput Ind Eng 57(3):1080–1088

Cheng TCE (1991) EPQ with process capability and quality assurance consideration. J Oper Res Soc 42(8):713–720

Hariga MA, Al-Fawzan MA (2005) Joint determination of target value and production run for a process with multiple markets. Int J Prod Econ 96(2):201–212

Lee MK, Kwon HM, Hong SH, Kim YJ (2007) Determination of the optimum target value for a production process with multiple products. Int J Prod Econ 107(1):173–178

Park T, Kwon HM, Hong SH, Lee MK (2011) The optimum common process mean and screening limits for a production process with multiple products. Comput Ind Eng 60(1):158–163

Pulak MFS, Al-Sultan KS (1996) The optimum targeting for a single filling operation with rectifying inspection. Omega 24(1):727–733

Chen CH, Lai MT (2007) Economic manufacturing quantity, optimum process mean and economic specification limits setting under the rectifying inspection plan. Eur J Oper Res 183(1):336–344

Markov AA (1971) Extension of the limit theorems of probability theory to a sum of variables connected in a chain. Reprinted in Appendix B of: Howard R (ed) Dynamic probabilistic systems, volume 1, Markov Chains. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Salamah, M. Optimum process parameters with imperfect infinite reworks. Int J Adv Manuf Technol 63, 1239–1246 (2012). https://doi.org/10.1007/s00170-012-3968-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3968-8