Abstract

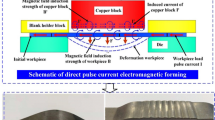

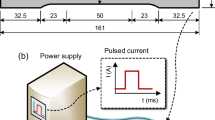

Pulse current-assisted hot-forming (PCAHF) of light metal alloy is developed due to lower energy consumption and higher efficiency. In this process, the metal sheet is designed in series in a pulse current circuit and heated directly by the pulse current. In addition, the ceramics mold is employed to avoid the heating current leaking. The Ti-6Al-4 V sheets are employed to improve the temperature distribution of the heated light metal alloy sheet. The effects of effective current density on the temperature and the rate of increase in temperature are studied by the pulse current heating experiment, and the effect of duty ratio on the forming property is studied by the forming experiments. Moreover, some light metal samples with different shapes are formed by the method of PCAHF. As the results, the hot forming with the merits of high-efficiency and low-energy consumption becomes possible.

Similar content being viewed by others

References

Liu J, Tan MJ, Yingyot A, Anders EWJ, Fong KS, Sylvie C (2011) Superplastic-like forming of non-superplastic AA5083 combined with mechanical pre-forming. Int J Adv Manuf Technol 52:123–129

Hwang YM, Lay HS (2003) Study on superplastic blow-forming in a rectangular closed-die. J Mater Process Technol 140:426–431

Feng YZ, Pan ZP (2003) Investigation of calculating the power of nonstandard periodic heat treatment resistance furnace. Heavy Cast Forg 99:19–22

Maki S, Harada Y, Mori K, Makino H (2002) Application of resistance heating technique to mushy state forming of aluminium alloy. J Mater Process Technol 125–126:477–482

Mori K, Maki S, Tanaka Y (2005) Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. CIRP Ann Manuf Technol 54(1):209–212

Yanagimoto J, Izumi R (2009) Continuous electric resistance heating–hot forming system for high-alloy metals with poor workability. J Mater Process Technol 209:3060–3068

Zhang CP, Zhang KF, Wang GF (2010) Dependence of heating rate in PCAS on microstructures and high temperature deformation properties of γ-TiAl intermetallic alloys. Intermet 18:834–840

Fan GQ, Sun FT, Meng XG, Gao L, Tong GQ (2010) Electric hot incremental forming of Ti-6Al-4 V titanium sheet. Int J Adv Manuf Technol 49:941–947

Zhu YH, To S, Lee WB, Liu XM, Jiang YB, Tang GY (2009) Effects of dynamic electropulsing on microstructure and elongation of a Zn-Al alloy. Mater Sci Eng A 501:125–132

Conrad H (2000) Electroplasticity in metals and ceramics. Mater Sci Eng A 287:276–287

Li MQ, Wu SC (1994) Effect of external electric field on the cavitation during the superplastic deformation of duralumin LY12CZ. Scr Metall et Mat 31(1):75–79

Sun PH, Wu HY, Tsai HH, Huang CC, Tzou MD (2010) Effect of pressurization profile on the deformation characteristics of fine-grained AZ31B Mg alloy sheet during gas blow forming. J Mater Process Technol 210:1673–1679

Siegert K, Jäger S, Vulcan M (2003) Pneumatic bulging of magnesium AZ 31 sheet metals at elevated temperatures. CIRP Ann Manuf Technol 52(1):241–244

Panicker R, Chokshi AH, Mishra RK, Verma R, Krajewski PE (2009) Microstructural evolution and grain boundary sliding in a superplastic magnesium AZ31 alloy. Acta Mater 57:3683–3693

Watanabe H, Tsutsui H, Mukai T, Kohzu M, Tanabe S, Higashi K (2001) Deformation mechanism in a coarse-grained Mg-Al-Zn alloy at elevated temperatures. Int J Plasticity 17:387–397

Khraisheh MK, Abu-Farha FK, Weinmann KJ (2007) Investigation of post-superplastic forming properties of AZ31 magnesium alloy. CIRP Ann Manuf Technol 56(1):289–292

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Jiang, S. & Zhang, K. Pulse current-assisted hot-forming of light metal alloy. Int J Adv Manuf Technol 63, 931–938 (2012). https://doi.org/10.1007/s00170-012-3934-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3934-5