Abstract

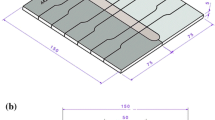

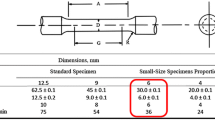

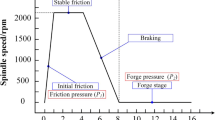

Equal-channel angular pressing is a material processing method that allows very high strains to be imposed, which leads to extreme work hardening and micro-structural refinement, with minimal change of external sample dimensions. It offers possibilities of good mechanical properties, such as high strength and ductility, while allowing flexibility of choice of alloy composition for better corrosion behavior, lower materials costs, and so on. This study characterizes for the first time the microstructure and properties of aluminum friction welded after severe plastic deformation via the equal-channel angular pressing method. In this study, 5,083 aluminum alloys, which were exposed to severe plastic deformation using square cross-sectional equal-channel angular pressing die, were joined with friction welding method. It was found that tensile and fatigue strengths of severe plastic deformed and welded specimens were higher than those of the purchased specimens. Hardness values were also consistent with the strength results. However, the refining of grain size as shown from microstructures results in a significant increase in hardness and mechanical properties.

Similar content being viewed by others

References

Kawasaki M, Balasubramanian N, Langdon TL (2011) Flow mechanisms in ultrafine-grained metals with an emphasis on superplasticity. Mater Sci Eng A 528:6624–6629

Segal VM, Reznikov VI, Drobyshevskiy AE, Kopylov VI (1981) Russ Metall 1:99

Shin DH, Kim YS, Lavernia EJ (2001) Acta Mater 49:2387

Chang S-Y, Ahn B-D, Hong S-K, Kamado S, Kojima Y, Shin DH (2005) Tensile deformation characteristics of a nano-structured 5083 Al alloy. J Alloys Compd 386:197–201

Ozel K (2005) The effect of severe plastic deformation methods to the mechanical properties of aluminum alloys. M.Sc. thesis. Graduate School of Natural and Applied Sciences of Trakya University, Edirne, Turkey

Liu Z, Wang Z (1999) Finite-element analysis of the load of equal-cross-section lateral extrusion. J Mater Process Technol 94:193–196

Lee DN (2000) An upper-bound solution of channel angular deformation. Scr Mater 43:115–118

Horita Z, Fujinami T, Nemoto M, Langdon TG (2001) Improvement of mechanical properties for Al alloys using equal-channel angular pressing. J Mater Process Technol 117:288–292

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) Paradox of strength and ductility in metals processed by severe plastic deformation. J Mater Res 17(1):5–8

Ivanisenko Y, Wunderlich RK, Valiev RZ, Fecht H-J (2003) Annealing behaviour of nanostructured carbon steel produced by severe plastic deformation. Scr Mater 47:947–952

Alkorta J, Sevillano JG (2003) A comparison of FEM and upper-bound type analysis of equal-channel angular pressing (ECAP). J Mater Process Technol 141:313–318

Balasubramanian N, Langdon TG (2005) An analysis of superplastic flow after processing by ECAP. Mater Sci Eng A 410–1:476–479

Kinley W (1979) Inertia welding: simple in principle and application. Weld and Met Fab October. 585–9

Murti KGK, Sundaresan S (1983) Parameter optimization in friction welding dissimilar materials. Met Constr 15(6):331–335

Akata HE, Sahin M (2003) An investigation on the effect of dimensional differences in friction welding of AISI 1040 Specimens. Ind Lubr Tribol 55(5):223–232

Sahin M, Akata HE (2003) Joining with friction welding of plastically deformed steel. J Mater Process Technol 142:239–246

Sahin M, Akata HE (2004) AN experimental study on friction welding of medium carbon and austenitic stainless steel components. Ind Lubr Tribol 56:122–129

Sahin M (2005) Joining with friction welding of high-speed steel and medium-carbon steel. J Mater Process Technol 168:202–210

Sahin M (2005) An investigation into joining of austenitic-stainless steels (AISI 304) with friction welding. Assem Autom 25(2):140–145

Sahin M (2004) Simulation of friction welding using a developed computer program. J Mater Process Technol 153–4:1011–1018

Sahin M, Akata HE, Özel K (2008) An experimental study on joining of severe plastic deformed aluminium materials with friction welding method. Mater Des 29(1):265–274

ASM (1985) ASM metals handbook, 8th edn. ASM, Metals Park, pp 1–7

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sahin, M., Balasubramanian, N., Misirli, C. et al. On properties at interfaces of friction welded near-nanostructured Al 5083 alloys. Int J Adv Manuf Technol 61, 935–943 (2012). https://doi.org/10.1007/s00170-011-3775-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3775-7