Abstract

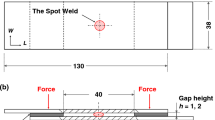

In cold rolling some surface defects, known as pits, are due to lubricant that, entrapped in the deep valleys of the surface roughness, is nearly incompressible and acts like an inclusion avoiding microcavity elimination. During the rolling process, when specific favorable conditions can be set up, the lubricant may be expelled by the microplasto-hydrodynamic lubrication (MPHL) mechanism and pits may be recovered. In this paper the Λm parameter, index of the MPHL, is investigated together with the neutral point position to better understand the practical process recommendations for surface defect recovery. By means of finite element analysis of a Sendzimir’cold rolling process, the sensitivity of these objective functions are studied by means of a design of experiment analysis changing the major process variables like back tension, friction coefficient, reduction parameter, initial thickness, and roll diameter.

Similar content being viewed by others

References

Ahmed R, Sutcliffe MPF (2001) An experimental investigation of the surface pit evolution during cold rolling or drawing of stainless steel strip. J Tribol 123:1–7

Le HR, Sutcliffe MPF (2003) Evolution of surface pits on stainless steel strip in cold rolling and strip drawing. J Tribol 125:384–390

Sutcliffe MPF, Geordiades F (2002) Characterisation of pit geometry in cold-rolled stainless steel strip. Wear 253:963–974

Sutcliffe MPF, Le HR, Ahmed R (2001) Modelling of micro-pit evolution in rolling or strip-drawing. J Tribol 123:791–798

Kenmochi K et al (1997) Effect of micro-defects on the surface brightness of cold-rolled stainless-steel strip. J Mater Process Tech 69(1–3):106–111

Wang Z, Dohda K, Haruyama Y (2005) Effects of entraining velocity of lubricant and sliding velocity on friction behaviour in stainless steel sheet rolling. Wear 260(3):249–257

Wilson WRD, Lo SW (1999) A theoretical model of micro-pool lubrication in metal forming. J Tribol 121:731–738

Mancini E, Sasso M, Amodio D, Ferretti R, Sanfilippo F (2011) Surface defect generation and recovery in cold rolling of stainless steel strips. J Tribol 133. doi:10.1115/1.4002218

Montgomery D (1991) Design of experiment. Wiley, New York

Cowper GR, Symonds PS (1958) Strain hardening and strain rate effect in the impact lading of cantilever beam. Applied Mathematics Report, Brown University

Peroni L, Peroni M (2006) Sviluppo di sistemi di prova per la caratterizzazione a trazione di lamiere ad elevata velocità di deformazione. Proceeding of XXXV AIAS Congress, Ancona, Italy

Sasso M, Newaz G, Amodio D (2008) Material characterization at high strain rate by Hopkinson bar tests and finite element optimization. Mat Sci Eng A 487:289–300

Dietenberger M, Buyuk M, Kan C-D (2005) Development of high strain-rate dependent vehicle model. LS-DYNA Anwenderforum, Bamberg

Cunat PJ (2000) Stainless steel proprieties for structural automotive applications. Proc Met Bull Internation Automot Mater Conference, Cologne

Mancini E, Newaz G, Sasso M, Ferretti R, Dhorajiya AP (2008) Effetto della velocità di deformazione sulla formazione dei difetti superficiali nella laminazione a freddo. Proceeding of XXXVII AIAS Congress, Rome, Italy

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mancini, E., Campana, F., Sasso, M. et al. Effects of cold rolling process variables on final surface quality of stainless steel thin strip. Int J Adv Manuf Technol 61, 63–72 (2012). https://doi.org/10.1007/s00170-011-3698-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3698-3