Abstract

A concept for sealing of polymer micro-structures by over-moulding with polystyrene was devised and investigated by both experiments and simulations. The depth to which the melt filled the structure, i.e. a groove in the surface of the insert, before solidification was compared with results from simulations by computational fluid dynamics software. In both experiments and simulations, there was clearly an increase of filling depth with groove width and, especially for wide grooves, with injection temperature. In the simulations, changes in prescribed heat transfer coefficient had the largest effect on filling depth in the narrowest grooves. Around the experimental groove widths, there was good agreement between experiments and simulations. It was concluded that sealing by over-moulding is feasible if the depth/width ratio of the structure is large enough which in this paper is larger than six, i.e. up to several times the filling depth in a corresponding metal or silicon structure.

Similar content being viewed by others

References

Breussin F (2009) Microfluidic market and technology trends. Ecole Polytechnique, Palaiseau, France. Available from http://www.polytechnique.fr. Accessed 22 October 2009

Studer V, Pépin A, Chen Y (2002) Nanoembossing of thermoplastic polymers for microfluidic applications. Appl Phys Lett 80(19):3614–3616

Kelly RT, Woolley AT (2003) Thermal bonding of polymeric capillary electrophoresis microdevices in water. Anal Chem 75(8):1941–1945

Klank H, Kutter JP, Geschke O (2002) CO2-laser micromachining and back-end processing for rapid production of PMMA-based microfluidic systems. Lab Chip 2:242–246

Boehm MW, Koelling K, Lu C, Lee J (2006) Fundamental processing characteristics in polymer micro/nano molding. In: Proc ANTEC 2006, pp 2546–2550

Lin C-H, Fu L-M, Tsai C-H, Chao C-H, Lan C-W (2005) Low azeotropic solvent sealing of PMMA microfluidic devices. In: Proc 13th int conf solid-state sens, actuators microsyst, pp 944–947

Yao D, Kim B (2002) Simulation of the filling process in micro channels for polymeric materials. J Micromechanics Microengineering 12:604–610

Despa MS, Kelly KW, Collier JR (1999) Injection molding of polymeric LIGA Harms. Microsyst Technol 6:60–66

Yu L, Koh CG, Lee LJ, Koelling KW, Madou MJ (2002) Experimental investigation and numerical simulation of injection molding with micro-features. Polym Eng Sci 42(5):871–888

Liou A-C, Chen R-H (2006) Injection molding of polymer micro- and sub-micron structures with high aspect ratios. Int J Adv Manuf Technol 28(11):1097–1103

Young W-B (2007) Analysis of filling distance in cylindrical microfeatures for microinjection molding. Appl Math Model 31:1798–1806

Bendada A, Derdouri A, Lamontagne M, Simard Y (2004) Analysis of thermal contact resistance between polymer and mold in injection molding. Appl Therm Eng 24(14–15):2029–2040

Yu L (2004) Experimental and numerical analysis of injection molding with microfeatures. Dissertation, Ohio State University

Sridhar L, Sedlak BM, Narh KA (2000) Parametric study of heat transfer in injection molding—effect of thermal contact resistance. J Manuf Sci Eng 122:698–705

Arzondo LM, Pino N, Carella JM, Pastor JM, Merino JC, Póveda J, Alonso C (2004) Sequential injection overmolding of an elastomeric ethylene-octene copolymer on a polypro pylene homopolymer core. Polym Eng Sci 44(11):2110–2116

Ezekoye OA, Lowman CD, Fahey MT, Hulme-Lowe AG (1998) Polymer weld strength predictions using a thermal and polymer chain diffusion analysis. Polym Eng Sci 38(6):976–991

Xue S-C, Phan-Thien N, Tanner RI (1998) Three dimensional numerical simulations of viscoelastic flows through planar contractions. J Non-Newton Fluid Mech 74:195–245

Katsikis N (2008) Particle-polymer interactions in melts of nano- and microcomposites with poly(methyl methacrylate) as Matrix Dissertation: University Erlangen-Nürnberg

Schweizer T (2004) A quick guide to better viscosity measurements of highly viscous fluids. Appl Rheol 14(4):197–201

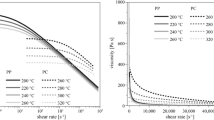

Yasuda K, Armstrong RC, Cohen RE (1981) Shear flow properties of concentrated solutions of linear and star branched polystyrenes. Rheol Acta 20(2):163–178

Hieber CA, Chiang HH (1989) Some correlations involving the shear viscosity of polystyrene melts. Rheol Acta 28(4):321–332

Sui C-P, McKenna GB (2006) Breakdown of the Cox-Merz rule and instability of polymer solutions in viscometric flows. In: Proc ANTEC 2006, pp 2351–2355

Piotter V, Mueller K, Plewa K, Ruprecht R, Hausselt J (2002) Performance and simulation of thermoplastic micro injection molding. Microsyst Technol 8:387–390

Barnes HA, Hutton JF, Walters K (1993) An introduction to rheology, 1st edn. Elsevier, Amsterdam

Williams ML, Landel RF, Ferry JD (1955) The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids J Am Chem Soc 77(14):3701–3707

Yu L, Lee LJ, Koelling KW (2004) Flow and heat transfer simulation of injection molding with microstructures. Polym Eng Sci 44(10):1866–1876

Gramberg HJJ (2005) Flow front instabilities in an injection moulding process. Dissertation, Eindhoven University of Technology

Andersson PÅ (2002) Computation of thermal development in injection mould filling based on the distance model. Dissertation, Linköping University

Author information

Authors and Affiliations

Consortia

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s00170-013-5541-5.

Rights and permissions

About this article

Cite this article

Mathias Vingaard., deClaville Christiansen, J. Sealing of polymer micro-structures by over-moulding. Int J Adv Manuf Technol 61, 161–170 (2012). https://doi.org/10.1007/s00170-011-3690-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3690-y