Abstract

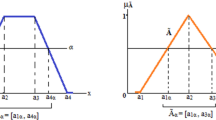

In a product development project, efficiently assigning tasks to employees is difficult, since high level of design imprecision and employees with multiple skills and different skill levels exist. The relative skill levels of employees are modeled by fuzzy numbers, and membership function is introduced to describe the confidential levels of the duration the task takes. The employees’ workloads in the project are calculated based on fuzzy sets theory and design structure matrix, and then multiple execution modes are generated by assigning different employees to the tasks. An optimization model of task assignment problem, which incorporates some factors not previously considered together (multiskilled employees and their skill levels, task iteration and the precedence constraints), is proposed. The objective function considered is to minimize the duration of the project and balance the workloads of the employees attending the project. Based on the information above, a genetic algorithm is utilized to find the optimum solution with regards to the considered objectives. A case of a die product development project is used to illustrate the problem and proposed method. The results verify the feasibility and effectiveness of this algorithm.

Similar content being viewed by others

References

Zamani R (2010) A parallel complete anytime procedure for project scheduling under multiple resource constraints. Int J Adv Manuf Technol 44(3):1–10

Elmaghraby SE (1977) Activity networks: project planning and control by network models. Wiley, New York

Sabzehparvar M, Seyed-Hosseini S (2008) A mathematical model for the multi-mode resource-constrained project scheduling problem with mode dependent time lags. J Supercomput 44(3):257–273

Wang J (2004) A fuzzy robust scheduling approach for product development projects. Eur J Oper Res 152(1):180–194

Moder JJ, Phillips CR, Davis EW (1983) Project management with CPM, PERT, and precedence diagramming. Van Nostrand Reinhold, New York

Golenko-Ginzburg D, Gonik A (1996) On-line control model for cost simulation network projects. J Oper Res Soc 47(2):266–283

Steward DV (1981) The design structure system: a method for managing the design of complex systems. IEEE Trans Eng Manag 28:71–74

Smith RP, Eppinger SD (1997) A predictive model of sequential iteration in engineering design. Manag Sci 43(8):1104–1120

Browning TR (2001) Applying the design structure matrix to system decomposition and integration problems: a review and new directions. IEEE Trans Eng Manag 48(3):292–306

Eppinger SD, Whitney DE, Smith RP, Gebala DA (1994) A model based method for organizing tasks in product development. Res Eng Des 6:1–13

Yassine A, Falkenburg D, Chelst K (1999) Engineering design management: an information structure approach. Int J Prod Res 37(13):2957–2975

Yassine A, Whitney DE, Lavine J, Zambito T (2000) Do-it-right-first-time (DRFT) approach to DSM restructuring. Proceedings of the 12th international conference on design theory and methodology, Sept. 10–13, Baltimore, MD, USA

Zheng TL, Li Z, Li D, Zhang S (2000) Re-engineering of the design process for concurrent engineering. Comput Ind Eng 38:479–491

Wei HQ (2007) Concurrent design process analysis and optimization for aluminum profile extrusion product development. Int J Adv Manuf Technol 33(7):652–661

Rogers JL, McCulley CM, Bloebaum CL (1996) Integrating a genetic algorithm into a knowledge-based system for ordering complex design processes. Proceedings, the 96 artificial intelligence on design conference, Stanford University, CA. Also NASA TM-110247

Altus SS, Kroo IM, Gage PJ (1996) A genetic algorithm for scheduling and decomposition of multi-disciplinary design problems. Trans ASAE 118(4):486–489

Yu T., Yassine A., and Goldberg D. (2003) A genetic algorithm for developing modular product architectures. Proceedings of the ASME 2003 international design engineering technical conferences, Chicago, 2–6 September

Whitfield RI, Duffy AHB, Gartzia-Etxabe LK (2005) Identifying and evaluating parallel design activities using the design structure matrix. International conference on engineering design, ICED 05, Melbourne, August 2005

Meier C, Yassine AA et al (2007) Design process sequencing with competent genetic algorithms. J Mech Des 129(6):566–585

Scott JA (1998) A strategy for modeling the design-development phase of a product, PhD Thesis, Department of Marine Technology, University of Newcastle upon Tyne, UK

Cai X, Li K (2000) A genetic algorithm for scheduling staff of mixed skills under multi-criteria. Eur J Oper Res 125(2):359–369

Corominas A, Ojeda J, Pastor R (2005) Multi-objective allocation of multi-function workers with lower bounded capacity. J Oper Res Soc 56(6):738–743

Corominas A, Pastor R, Rodriguez E (2006) Rotational allocation of tasks to multi-functional workers in a service industry. Int J Prod Econ 103(1):3–9

Campbell G, Diaby M (2002) Development and evaluation of an assignment heuristic for allocating cross-trained workers. Eur J Oper Res 138(1):9–20

Valls V, Pérez Á, Quintanilla S (2009) Skilled workforce scheduling in service centres. Eur J Oper Res 193(3):791–804

Joglekar NR, Ford DN (2005) Product development resource allocation with foresight. Eur J Oper Res 160(1):72–87

Smith RP, Eppinger SD (1997) Identifying controlling features of engineering design iteration. Manag Sci 43(3):276–293

McCarthy DJ (2008) Phantom work: design iteration timing in new product development. PhD Thesis. Sloan School of Management, Massachusetts Institute of Technology

Goldberg DE (1989) Genetic algorithms in search, optimization, and machine learning. Addison, Boston

Acknowledgments

The project was supported by the Shanghai Science and Technology Innovation Action Plan (09dz1124600, 10dz1121600), the National High-Tech. R&D Program for CIMS, China (no. 2007AA04Z140) and the Research Fund for Doctoral Program of Higher Education, China (no. 20070248020). The authors express sincere appreciation to the anonymous referees for their helpful comments to improve the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, H., Chu, X. Task assignment with multiskilled employees and multiple modes for product development projects. Int J Adv Manuf Technol 61, 391–403 (2012). https://doi.org/10.1007/s00170-011-3686-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3686-7