Abstract

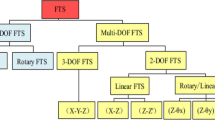

This paper describes the development of the fast tool servo (FTS) in detail and categorizes existing FTSs according to different principles. The characteristics and differences of these FTSs have been analyzed. A flexure-based long-stroke FTS system for diamond turning is presented with displacement range of 1 mm and bandwidths of 10 Hz. The vertical jump is about 0.045 μm, and the full stroke tracking error is less than 0.15%. A voice coil motor and a piezoelectric actuator are used as the driving elements, and two flexure hinges are developed as the guide mechanisms. The FTS utilizes a linear encoder and a capacitive sensor to measure the displacement of the tool for closed-loop control. The electromechanical design of the FTS and its motion analysis are described. Experimental tests have been carried out to verify the performance of the FTS system. This long-stroke FTS has the advantage of easy machining, high resonance frequency, and error compensation in y-axis direction.

Similar content being viewed by others

References

Patterson SR, Magreb EB (1985) Design and testing of a fast tool servo for diamond turning. Precis Eng 7(3):123–128. doi:10.1016/0141-6359(85)90030-3

Ku S, Larsen G, Cetinkunt S (1998) Fast tool servo control for ultra-precision machining at extremely low feed rates. Mechatronics 8:381–393. doi:10.1016/S0957-4158(97)00063-9

Zhu W-H, Jun MB, Altintas Y (2001) A fast tool servo design for precision turning of shafts on conventional CNC lathes. Int J Mach Tool Manu 41(6):953–965. doi:10.1016/S0890-6955(00)00118-8

Gan S-W, Lim H-S, Rahman WF (2007) A fine tool servo system for global position error compensation for a miniature ultra-precision lathe. Int J Mach Tool Manu 47:1302–1310. doi:10.1016/j.ijmachtools.2006.08.023

Kim HS, Kim EJ (2003) Feed-forward control of fast tool servo for real-time correction of spindle error in diamond turning of flat surface. Int J Mach Tool Manu 43:1177–1183. doi:10.1016/S0890-6955(03)00156-1

Crudele M, Kurfess TR (2003) Implementation of a fast tool servowith repetitive control for diamond turning. Mechatronics 13:243–257. doi:10.1016/S0957-4158(01)00036-8

Ludwick SJ Jr (1999) A Rotary Fast Tool Servo for Diamond Turning of Asymmetric Optics. Dissertation, MIT

Brecher C, Lange S, Merz M, Niehaus F, Winterschladen M (2006) Off-axis machining of NURBS freeform surfaces by Fast Tool Servo Systems. In: Proceedings of the 4M 2006 Second International Conference on Multi-Material Micro Manufacture, Grenoble, France, pp 59–62. doi:10.1016/B978-008045263-0/50013-1

Lu XD (2005) Electromagnetically-Driven Ultra-Fast Tool Servos for Diamond Turning. Doctor Dissertation, MIT

Montesanti RC (2005) High Bandwideth Rotary Fast Tool Servo and a Hybrid Rotary/Linear Electricmagnetic Actuator. Dissertation, MIT

Buescher NP (2005) Live-Axis Turning. Dissertation, NCSU

Zhong ZW, Lin G (2006) Ultrasonic assisted turning of an aluminium-based metal matrix composite reinforced with SiC particles. Int J Adv Manuf Technol 27:1077–1081. doi:10.1007/s00170-004-2320-3

Sosnicki O, Pages A, Pacheco C, Malillard T (2010) Servo piezoelectric tool SPT400MML for the fast and precise machining of free forms. Int J Adv Manuf Technol. doi:10.1007/s00170-009-21-6

Ma H, Dejin Hu, Zhang K (2005) A fast tool feeding mechanism using piezoelectric actuators in noncircular turning. Int J Adv Manuf Technol. doi:10.1007/s00170-004-2168-6

Dan Wu, Chen K (2010) Chatter suppression in fast tool servo-assisted turning by spindle speed variation. Int J Mach Tool Manu 50(12):1038–1047. doi:10.1016/j.ijmachtools.2010.09.001

Kim Ho-Sang, Kim Sang-In, Lee Kwang-Il, Lee D-H, Bang Y-B, Lee Kyo-Il (2009) Development of a programmable vibration cutting tool for diamond turning of hardened mold steels. Int J Adv Manuf Technol 40:26–40. doi:10.1007/s00170-007-1311-6

http://www.kineticceramics.com/optics_fabrication_equipment.html. Accessed 26 June 2010

Kima Ho-Sang, Lee Kwang-Il, Lee K-M, Bang Y-B (2009) Fabrication of free-form surfaces using a long-stroke fast tool servo and corrective figuring with on-machine measurement. Int J Mach Tool Manu 49:991–997. doi:10.1016/j.ijmachtools.2009.06.011

Noh YJ, Nagashima M, Arai Y, Gao W (2009) Fast Positioning of Cutting Tool by a Voice Coil Actuator for Micro-Lens Fabrication. Int J of Automation Technology 3(3):257–262

Zdanowicz EM (2009) Design of a Fast Long Range Actuator-FLORA II. Dissertation, NCSU

Byl MF (2005) Design and Control of a Long Stroke Fast Tool Servo. Dissertation, MIT

http://www.precitech.com/2010_Precitech_FTS.html. Accessed 6 June 2010

http://www.nanotechsys.com/accessories/nanotech-250upl-factory-options. Accessed 22 June 2010

Rakuff S, Cuttino JF (2009) Design and testing of a long-range, precision fast tool servo system for diamond turning. Precis Eng 33(1):18–25. doi:10.1016/j.precisioneng.2008.03.001

Rakuff S (2004) Development of a precision long-range fast tool servo system for diamond turning. Dissertation, NCUC

Yin ZQ, Dai YF, Li SY, Guan CL, Tie GP (2010) Fabrication of off-axis aspheric surfaces using a slow slide tool servo. Int J Mach Tool Manu 51:404–410. doi:10.1016/j.ijmachtools.2011.01.008

Paros JM, Weisbord L (1965) How to design a flexure hinge. Mach Des 37:151–157

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Zhou, X., Xu, P. et al. A flexure-based long-stroke fast tool servo for diamond turning. Int J Adv Manuf Technol 59, 859–867 (2012). https://doi.org/10.1007/s00170-011-3556-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3556-3