Abstract

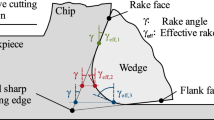

The influence of the cutting edge micro geometry on cutting process and on tool performance is subject of several research projects. Recently published papers focus on optimising the cutting edge rounding. The results are partly inconsistent. Unfortunately, no international standard yet exists to properly describe the cutting edge micro geometry. This is seen as the root cause for detected discrepancies. To develop a common understanding for the influence of rounded cutting edges, it is indispensable to use the same basis to characterise the edge profile. This paper gives a review on existing characterisation methods, analyses the difficulties in their application and discusses different modelling ideas to describe the cutting edge profile. Based hereon, a new algorithm and geometrical parameterisation of the cutting edge is proposed, which reduces uncertainties and difficulties in the application of currently available methods. The proposed method considers measurement uncertainties and is robust against form errors and creates thus the basis required for the study of the influence of rounded cutting edges.

Similar content being viewed by others

References

Albrecht P (1960) New developments in the theory of the metal cutting process: the ploughing process in metal cutting. ASME J Eng Ind 81(1960):348–358

Risse K (2006) Einflüsse von Werkzeugdurchmesser und Schneidkantenverrundung beim Bohren in Stahl, Dissertation, RWTH Aachen Technical University

Hentschel B, Höppner J, Richter J (1978) Einfluss von Schneidkeilgeometrie und Schnittbedingungen auf die Komponenten der Zerspankraft im Orthogonalschnitt. Wissenschaftliche Zeitschrift der Technischen Universität Dresden 27(5):1013–1018

Denkena B, Friehmuth T, Fedorenke S, Groppe M (2002) An der Schneide wird das Geld verdient—Neue Parameter zur Charakterisierung der Schneidengeometrien an Zerspanwerkzeugen, Fertigung. Sonderausgabe Werkzeuge 12(2002):24–26

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf. doi:10.1016/j.ijmachtools.2009.08.002

Chen R, Wenxiang L, Zhengchuan L (1985) The role of the radius of the tool-lip of HSS cutting tools, First International Metal Cutting Conference, Guangzhou, China, pp. 67–73

Enssle O (2008) Standwegverlängerung durch gezielte Änderung der Mikrogeometrie an Diamantwerkzeugen für die Holz- und Holzwerkstoffbearbeitung, Dissertation, Technical University Stuttgart

Xu G (1996) Einfluss der Schneidkantenform auf die Oberflächenausbildung beim Hochgeschwindigkeitsfraesen mit Feinkornhartmetall, Dissertation, Technical University Darmstadt

Bouzakis KD, Michailidis N, Skordaris G, Kombogiannis S, Hadjiyiannis S, Efstathiou K, Erkens G, Rambadt S, Wirth I (2002) Effect of the cutting edge radius and its manufacturing procedure, on the milling performance of PVD coated cemented carbide inserts. CIRP Ann Manuf Technol 51(1):61–64

Bouzakis KD, Michailidis N, Skordaris G, Kombogiannis S, Hadjiyiannis S, Efstathiou K, Pavlidou E, Erkens G, Rambadt S, Wirth I (2003) Optimisation of the cutting edge roundness and its manufacturing procedures of cemented carbide inserts, to improve their milling performance after a PVD coating deposition. Surf Coat Technol 163–164:625–630

Biermann D, Terwey I (2008) Cutting edge preparation to improve drilling tools for HPC processes. CIRP J Manuf Sci Technol 1(2):76–80

Elsharkawy M (1975) Einfluss des Ecken- und Schneidkantenradius auf die Oberflächengüte beim Feindrehen. Fertigungstechnik und Betrieb 25(4):230–233

Denkena B, Boehnke D, de León-García L (2005) Einfluss der Schneidkantengeometrie auf die Zerspankräfte und auf das Verschleissverhalten. ZWF 100(9):490–494

Denkena B, de Leon L, Bassett E (2009) Fünf-Achs-Bürsten zur Schneidkantenpräparation. ATZproduktion 2(1):32–35

Cortés R., Julio C (2009) Cutting edge preperation of precision tools by applying micro-abrasive jet machining and brushing, Dissertation. Kassel University

ISO 25178–6:2010, Geometrical product specifications (GPS)—Surface texture: Areal—Part 6: Classification of methods for measuring surface texture, International Organization for Standardization, Geneva

Denkena B (2008) CIRP STC-C minutes, Annex A, August 2008

ISO 3002-1 (1982–08) Basic quantities in cutting and grinding; Part 1 : Geometry of the active part of cutting tools; General terms, reference systems, tool and working angles, chip breakers, International Organization for Standardization, Geneva

DIN 6582 (1988–02) Begriffe der Zerspantechnik; Ergänzende Begriffe am Werkzeug, am Schneidkeil und an der Schneide, German Institute for Standardization, Berlin

Tikal F, Holsten S (2006) Neue Anforderungen erfordern neue Werkzeuge. VDI-Z 3:44–46

Lamers N (1992) Verrunden—Baustein der automatisierten Wendeplattenherstellung. VDI-Z 134(2):59–62

Tikal F, Holsten S (2008) Bedeutung der Kantenverrundung bei Zerspanungswerkzeugen, In-house trade fair 2008 of OTEC Präzisionsfinish GmbH, 8.05.2008

vom Hemdt A, Pfeifer T (1989) Idealgeometrische Ersatzelemente für Standard-Messaufgaben. VDI Berichte 751:321–335

DIN EN ISO 1101 (2008–08) Geometrical Product Specifications (GPS)—Geometrical tolerancing—Tolerances of form, orientation, location and run-out (ISO 1101:2004); German version EN ISO 1101:2005, German Institute for Standardization, Berlin

DIN EN ISO 12181–1 (2009–07) Geometrical product specifications (GPS)—Roundness—Part 1: Vocabulary and parameters of roundness (ISO/DIS 12181–1:2009); Intended as replacement for DIN ISO/TS 12181–1 (2008–05), German Institute for Standardization, Berlin

DIN 1319–1 (1995–01) Grundlagen der Meßtechnik—Teil 1: Grundbegriffe, German Institute for Standardization, Berlin

Hernla M (1992) Abschätzung der Messunsicherheit bei Koordinatenmessungen unter den Bedingungen der industriellen Fertigung, VDI-Fortschrittberichte Reihe 2, Nr. 274, VDI-Verlag, Düsseldorf

Weber H (2001) Unsicherheitsbetrachtungen bei Kreismessungen in der Fertigungsmesstechnik, 11. Internationale Geodätische Woche, Obergurgl

Denkena B, Kramer N, Siegel F, Kästner J (2007) Leistungsoptimierung an der Schneidkante, VDI-Z Special Werkzeuge, (08) 2007, pp. 24–26

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wyen, CF., Knapp, W. & Wegener, K. A new method for the characterisation of rounded cutting edges. Int J Adv Manuf Technol 59, 899–914 (2012). https://doi.org/10.1007/s00170-011-3555-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3555-4