Abstract

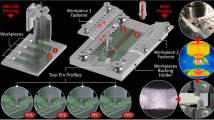

Two-component micropowder injection molding allows two different materials and, hence, two different functions to be integrated in one microdevice. This requires both components to be matched precisely. Therefore, high dimensional accuracy is essential in the successful development of a two-component micropart. This paper is about studies of the accuracy of the diameters of the inner hole of a gear wheel to be used as the first component of a shaft-to-collar connection. Diameters were measured in two defined directions, oriented 90° relative to each other. Items discussed are the size accuracy of green bodies and sintered specimens as well as the effects of different gating concepts. Sometimes, the inner hole is eccentric, depending on the gating concept employed. It was shown that a point-shaped gate can exert pressure on the feedstock nearby, thus causing deformation and reducing the diameter in these areas compared to the diameter in areas far from the gating system. The results also show that the eccentricity of the inner hole after sintering differs from that measured on green bodies, which is an indication of anisotropy in sintering. Moreover, the types of powder were seen to have an effect.

Similar content being viewed by others

References

Beck M, Piotter V, Ruprecht R, Haußelt J (2006) Dimensional tolerances of micro precision parts made by ceramic injection moulding. 4M 2006 Conference, 20th–22nd September 2006. Grenoble, France, pp 135–138

Beck M, Piotter V, Ritzhaupt-Kleissl H-J, Hausselt J (2008) Statistical analysis on the quality of precision parts in ceramic injection moulding. Proc. 10th Euspen Conference, 18th–22nd May 2008, Zurich, Switzerland, vol. 2, pp 179–183

Imgrund P, Rota A, Hartwig T, Petzoldt F, Simchi A (2005) Adjustment of Materials and Sintering processes for MIM of bi-material parts. In: Proc. Euro PM 2005, 2nd–5th October 2005, Prague, Czech Republic-EPMA, Shrewsbury, vol. 2, pp. 307–312

Imgrund P, Rota A, Wiegmann M (2007) Getting better bonding at tiny interfaces. Metalpowder Rep 62(3):31–34

Imgrund P, Rota A, Simchi A (2008) Microinjection moulding of 316 L/17-4PH and 316 L/Fe powders for fabrication of magnetic-nonmagnetic bimetals. J Mater Process Technol 200:259–264

Piotter V, Holstein N, Plewa K, Ruprecht R, Haußelt J (2004) Replication of microcomponents by different variants of injection molding. Microsyst Technol 10:547–551

Finnah G, Orlygsson G, Piotter V, Ruprecht R, Haußelt J (2005) Injection molding processes for integration and assembly in MST. In: Michel B (ed) The World of electronic packaging and system integration. ddp Goldenbogen, Dresden, pp 314–319

Piotter V, Beck M, Ritzhaupt-Kleissl H-J, Ruh A, Hausselt J (2008) Recent developments in micro ceramic injection molding. Int J Mat Res 99:1157–1162

Ruh A, Hanemann T, Heldele R, Piotter V, Ritzhaupt-Kleissl H-J, Hausselt J (2011) Development of two-component micropowder injection molding (2C-MicroPIM): characteristics of applicable materials. Int J Appl Ceram Technol 8:194–202

Ruh A, Piotter V, Plewa K, Ritzhaupt-Kleissl H-J, Hausselt J (2009) Development of two-component micropowder injection molding (2 C-MicroPIM)—process development. Int J Appl Ceram Technol. doi:10.1111/j.1744-7402.2009.02468.x

Piotter V, Prokop J, Ritzhaupt-Kleissl H-J, Ruh A, Hausselt J (2010) Multi-component microinjection moulding-trends and developments. Int J Adv Manuf Technol 47:63–71

Moritz T (2008) Two-component ceramic injection moulded (CIM) parts for the automotive and railway sectors. Powder Injection Moulding Int 2(4):38–39

Moritz T, Mannschatz A (2009) Ceramic components for automotive and railway applications made by two-component ceramic injection moulding. Proc. Euro PM 2009, 12th–14th October 2009, Copenhagen, Denmark. EPMA, Shrewsbury, vol. 2, pp 123–128

Heldele R, Schulz M, Kauzlaric D, Korvink JG, Haußelt J (2006) Micro powder injection molding: process characterization and modeling. Microsyst Technol 12:941–946

Kauzlarić D, Lienemann J, Pastewka L, Greiner A, Korvink JG (2008) Integrated process simulation of primary shaping: multi scale approaches. Microsyst Technol 14:1789–1796

Greiner A, Kauzlaric D, Korvink JG, Heldele R, Schulz M, Piotter V, Hanemann T, Weber O, Haußelt J (2011) Simulation of micro powder injection moulding: powder segregation and yield stress effects during form filling. J Eur Ceram Soc. doi:10.1016/j.jeurceramsoc.2011.02.008

Ruh A, Dieckmann A-M, Heldele R, Piotter V, Ruprecht R, Munzinger C, Fleischer J, Haußelt J (2008) Production of two-material micro-assemblies by two-component powder injection molding and sinter-joining. Microsyst Technol 14:1805–1811

Heldele R, Rath S, Merz L, Butzbach R, Hagelstein M, Haußelt J (2006) X-ray tomography of powder injection moulded micro parts using synchrotron radiation. Nucl Instr Meth Phys Res B 246:211–216

Hanemann T, Heldele R (2010) Modern alchemy: ceramic feedstock optimization by surfactant screening. cfi/Ber DKG 87(4):E38–E40

Ruh A, Piotter V, Plewa K, Ritzhaupt-Kleissl H-J, Haußelt J (2010) Effects of material improvement and injection moulding tool design on the movability of sintered two-component micro parts. Microsyst Technol 16:1989–1994

Gietzelt T, Piotter V, Ruprecht R, Hausselt J (2002) Manufacturing of isolated ceramic microstructures. Microsyst Technol 9:99–103

Gietzelt T, Jacobi O, Piotter V, Ruprecht R, Hausselt J (2007) Manufacturing and characterization of isolated microparts made by PIM for a micro annular gear pump and a micro gearwheel mould insert. PIM International 1(2):48–53

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruh, A., Piotter, V., Plewa, K. et al. Studies on size accuracy of microgear wheels produced by powder injection molding of zirconia feedstocks. Int J Adv Manuf Technol 58, 1051–1059 (2012). https://doi.org/10.1007/s00170-011-3461-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3461-9