Abstract

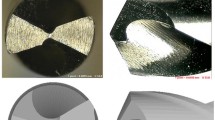

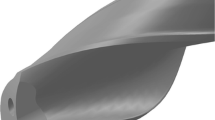

This paper presents an experimental investigation to verify the feasibility and effectiveness of heat pipe cooling in drilling operations. The basic idea is to insert a heat pipe at the center of the drill tool with the evaporator close to the drill tip and the condenser at the end of the drill. Consequently, the heat generated at the tool–chip interface can be removed by convection heat transfer. Experimental studies were involved in three cases, including solid drill without coolant, solid drill with coolant, and heat pipe drill. Drilling tests were conducted on a CNC machining center with full immersion cutting. The cast iron square block was used as the workpiece, and the high-speed steel was chosen for the drill tool material. Flank wear is considered as the criterion for tool failure, and the wear was measured using a Hisomet II Toolmaker’s microscope. The tests were conducted until the drill was rejected when an average flank wear greater than 0.10 mm was recorded. The results demonstrate that using a heat pipe in the drilling process can effectively perform thermal management comparable to the flooding coolant cooling used pervasively in the manufacturing industry, extending the tool life of the drill.

Similar content being viewed by others

References

Zhu L, Jen TC, Yen YH (2010) Numerical investigation of heat pipe cooling in drilling applications. J Mech Eng 61:233–254

Daniels T, Al JF (1975) Investigation of the factor affecting the performance of a rotating heat pipe. Int J Heat Mass Transf 18:961–973

Stephenson DA, Agapiou JS (2006) Metal cutting theory and practice. CRC Taylor & Francis, Boca Raton

Judd RL, Aftab K, Elbestawi MA (1995) An investigation of a heat pipe cooling system for use in turning on a lathe. Int J Adv Manuf Technol 10:357–366

Gutierrez G (2002) Investigation of heat pipes for drilling applications. Ph.D. Dissertation, University of Wisconsin, Milwaukee

Chiou RY, Lu L, Chen JS-J, North MT (2007) Investigation of dry machining with embedded heat pipe cooling by finite element analysis and experiments. Int J Adv Manuf Technol 31:905–914

Haq AN, Tamizharasan T (2006) Investigation of the effects of cooling in hard turning operations. Int J Adv Manuf Technol 30:808–816

Trent E, Wright P (2000) Metal cutting. Butterworth/Heinemann, Oxford

Jen TC, Gutierrez G, Jadhav. R (2002) Progress report for the heat pipe drill temperatures simulations and experimental measurement, at Lamb Technicon Machining Systems, Warren, Michigan

Labataille J, Manjunathaiah J (1999) Evaluation of drilling with heat pipe cooling. Internal Report Lx-0437, Lamb Technicon Machining Systems

Ding Y, Hong SY (1998) Improvement of chip breaking in machining low carbon steel by cryogenically pre-cooling the workpiece. ASME J Manuf Sci Eng 120:76–83

Peterson GP (1994) An introduction to heat pipes: modeling, testing, and applications. Wiley, New York

Jen TC, Chen YM, Gutierrez G (2003) Thermal performance of heat pipe drill: experimental study. Proceedings of NHTC03: ASME Summer Heat Transfer Conference. Las Vegas, Nevada, USA, pp 1–8

Jen TC, Eapen S, Gutierrez G (2003) Nonlinear numerical analysis in transient cutting tool temperatures. ASME J Manuf Sci Eng 125:48–56

Sato M, Ueda T, Tanaka H (2007) An experimental technique for the measurement of temperature on CBN tool face in end milling. Int J Mach Tools Manuf 47:2071–2076

Mills B, Mottishaw T, Chisholm A (1981) The application of scanning electronic microscopy to the study of temperatures and temperature distribution in M2 high speed steel twist drills. CIRP Ann 30:15–27

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Jen, TC., Yin, CL. et al. Experimental analyses to investigate the feasibility and effectiveness in using heat pipe-embedded drills. Int J Adv Manuf Technol 58, 861–868 (2012). https://doi.org/10.1007/s00170-011-3436-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3436-x