Abstract

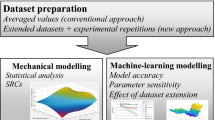

Surface roughness plays a key role in the performance of machined components—specially dies and moulds—manufactured for the aerospace and automotive industries, among others. However, roughness can only be measured off-line after the part has been machined, when cutting conditions may no longer be adjusted to surface roughness requirements. A reliable surface roughness prediction application is presented in this paper. It is based on ensemble learning for vertical high-speed milling operations with ball-end mills for finishing operations on quenched steel 1.2344 (AISI H13) that are widely used in the manufacture of moulds and dies. The new approach was validated with an experimental dataset that includes geometrical tool factors, cutting conditions, dynamic factors and lubricant type. An intensive comparison with an artificial neural network approach for the same dataset is included, to reveal the improvements of the new technique over other well-established ones for this industrial problem. This comparison shows that ensemble learning can by-pass the time-consuming task of tuning neural network parameters and can also improve prediction model accuracy, both of which are features that could lead to greater use of these kinds of prediction models in real workshops. Finally, a methodology, based on this new approach, is presented, in order to illustrate how the prediction model can be used in workshops to optimize cutting conditions in terms of their surface quality and productivity.

Similar content being viewed by others

References

Benardos PG, Vosniakos GC (2003) Predicting surface roughness in machining: a review. Int J Mach Tools Manuf 43(8):833–844

Chandrasekaran M, Muralidhar M, Krishna C, Dixit U (2010) Application of soft computing techniques in machining performance prediction and optimization: a literature review. Int J Adv Manuf Technol 46(5):445–464

International Organization for Standardization. ISO-4287 (1997) Geometrical product specifications (GPS)—surface texture: profile method—terms, definitions and surface texture parameters

International Organization for Standardization. ISO-4288 (1996) Geometrical product specifications (GPS): rules and procedures for the assessment of surface texture

Martellotti ME (1941) An analysis of the milling process. Trans ASME 63:667–700

Martellotti ME (1945) An analysis of the milling process. Part II. Down milling. Trans ASME 67:233–251

Quintana G, de Ciurana J, Ribatallada J (2010) Surface roughness generation and material removal rate in ball end milling operations. Mater Manuf Process 25(6):386–398

Abouelatta OB, Mádl J (2001) Surface roughness prediction based on cutting parameters and tool vibrations in turning operations. J Mater Process Technol 118(1-3):269–277

Ghani AK, Choudhury IA, Husni (2002) Study of tool life, surface roughness and vibration in machining nodular cast iron with ceramic tool. J Mater Process Technol 127(1):17–22

Brinksmeier E, Aurich JC, Govekar E, Heinzel C, Hoffmeister H-W, Klocke F, Peters J, Rentsch R, Stephenson DJ, Uhlmann E, Weinert K, Wittmann M (2006) Advances in modeling and simulation of grinding processes. CIRP Ann (Manuf Technol) 55(2):667–696

Sharma V, Dhiman S, Sehgal R, Sharma S (2008) Estimation of cutting forces and surface roughness for hard turning using neural networks. J Intell Manuf 19(4):473–483

Markopoulos AP, Manolakos DE, Vaxevanidis NM (2008) Artificial neural network models for the prediction of surface roughness in electrical discharge machining. J Intell Manuf 19(3):283–292

Ciurana J, Arias G, Ozel T (2009) Neural network modeling and particle swarm optimization (PSO) of process parameters in pulsed laser micromachining of hardened AISI H13 steel. Mater Manuf Process 24(3):358–368

Quintana G, Garcia-Romeu M, Ciurana J (2009) Surface roughness monitoring application based on artificial neural networks for ball-end milling operations. J Intell Manuf. doi:10.1007/s10845-009-0323-5

Lo SP (2003) An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling. J Mater Process Technol 142(3):665–675

Ho WH, Tsai JT, Lin BT, Chou JH (2009) Adaptive network-based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm. Expert Syst Appl 36(2):3216–3222

Chen JC, Savage M (2001) A fuzzy-net-based multilevel in-process surface roughness recognition system in milling operations. Int J Adv Manuf Technol 17(9):670–676

Iqbal A, He N, Li L, Dar NU (2007) A fuzzy expert system for optimizing parameters and predicting performance measures in hard-milling process. Expert Syst Appl 32(4):1020–1027

Samanta B, Erevelles W, Omurtag Y (2008) Prediction of workpiece surface roughness using soft computing. Proc Inst Mech Eng B J Eng Manuf 222(10):1221–1232

Correa M, Bielza C, de J. Ramirez M, Alique JR (2008) A Bayesian network model for surface roughness prediction in the machining process. Int J Syst Sci 39(12):1181–1192

Correa M, Bielza C, Pamies-Teixeira J (2009) Comparison of Bayesian networks and artificial neural networks for quality detection in a machining process. Expert Syst Appl 36(3):7270–7279

Brezocnik M, Kovacic M (2003) Integrated genetic programming and genetic algorithm approach to predict surface roughness. Mater Manuf Process 18(3):475–491

Brezocnik M, Kovacic M, Ficko M (2004) Prediction of surface roughness with genetic programming. J Mater Process Technol 157–158:28–36

Prakasvudhisarn C, Kunnapapdeelert S, Yenradee P (2009) Optimal cutting condition determination for desired surface roughness in end milling. Int J Adv Manuf Technol 41(5):440–451

Bishop CM (1995) Neural networks for pattern recognition. Oxford University Press, Oxford

Oza N, Tumer K (2008) Classifier ensembles: select real-world applications. Information Fusion 9(1):4–20

Kuncheva LI (2004) Combining pattern classifiers: methods and algorithms. Wiley-Interscience, New York. ISBN-10: 0471210781; ISBN-13: 978-0471210788

Dietterich TG (2000) Ensemble methods in machine learning. In: Kittler J, Roli F (ed) Multiple classifier systems. Lecture notes in computer science, vol 1857. Springer, New York pp 1–15

Cho S, Binsaeid S, Asfour S (2010) Design of multisensor fusion-based tool condition monitoring system in end milling. Int J Adv Manuf Technol 46(5):681–694

Binsaeid S, Asfour S, Cho S, Onar A (2009) Machine ensemble approach for simultaneous detection of transient and gradual abnormalities in end milling using multisensor fusion. J Mater Process Technol 209(10):4728–4738

Bustillo A, Ukar E, Rodriguez JJ, Lamikiz A (2011) Modelling of process parameters in laser polishing of steel components using ensembles of regression trees. Int J Comput Integr Manuf (in press)

Bauer E, Kohavi R (1999) An empirical comparison of voting classification algorithms: bagging, boosting, and variants. Mach Learn 36:105–139

Webb GI (2000) MultiBoosting: a technique for combining boosting and wagging. Mach Learn 40(2):159–196

Maimon O, Rokach L (eds) (2010) Data mining and knowledge discovery handbook, 2nd edn. Springer, New York

Dietterich TG (2000) Ensemble methods in machine learning. In: Proceedings of the first international workshop on multiple classifier systems, MCS ’00, London, UK. Springer, Berlin, pp 1–15

Dzeroski S, Zenko B (2004) Is combining classifiers with stacking better than selecting the best one? Mach Learn 54(3):255–273

Kuncheva LI (2001) Combining classifiers: soft computing solutions. In: Pal SK (ed) Pattern recognition: from classical to modern approaches. World Scientific, Singapore, pp 427–452

Dietterich TG (2000) Ensemble methods in machine learning. In: Proceedings of the first international workshop on multiple classifier systems, MCS ’00, London, UK. Springer, Berlin, pp 1–15

Breiman L (1996) Bagging predictors. Mach Learn 24(2):123–140

Freund Y, Schapire RE (1996) Experiments with a new boosting algorithm. In: International conference on machine learning, pp 148–156

Ho TK (1998) The random subspace method for constructing decision forests. IEEE Trans Pattern Anal Mach Intell 20:832–844

Freund Y, Schapire RE (1997) A decision-theoretic generalization of on-line learning and an application to boosting. J Comput Syst Sci 55(1):119–139

Hall M, Frank E, Holmes G, Pfahringer B, Reutemann P, Witten IH (2009) The WEKA data mining software: an update. ACM SIGKDD Explorations Newsletter 11(1):10–18

Dietterich TG (2000) An experimental comparison of three methods for constructing ensembles of decision trees: bagging, boosting, and randomization. Mach Learn 40(2):139–157

García-Pedrajas N, García-Osorio C, Fyfe C (2007) Nonlinear “boosting” projections for ensemble construction. J Mach Learn Res 8:1–33

Long P, Servedio R (2010) Random classification noise defeats all convex potential boosters. Mach Learn 78(3):287–304

Maciej G, Bustillo A, Zawistowski P (2010) A soft computing system using intelligent imputation strategies for roughness prediction in deep drilling. J Intell Manuf 1–11. doi:10.1007/s10845-010-0478-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bustillo, A., Díez-Pastor, JF., Quintana, G. et al. Avoiding neural network fine tuning by using ensemble learning: application to ball-end milling operations. Int J Adv Manuf Technol 57, 521–532 (2011). https://doi.org/10.1007/s00170-011-3300-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3300-z