Abstract

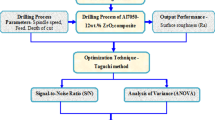

This paper presents a statistical analysis of process parameters for surface roughness in drilling of Al/SiCp metal matrix composite. The experimental studies were conducted under varying spindle speed, feed rate, drill type, point angle of drill, and heat treatment. The settings of drilling parameters were determined by using Taguchi experimental design method. The level of importance of the drilling parameters is determined by using analysis of variance. The optimum drilling parameter combination was obtained by using the analysis of signal-to-noise ratio. Through statistical analysis of response variables and signal-to-noise ratios, the determined significant factors were the feed rate and tool type. Confirmation tests verified that the selected optimal combination of process parameter through Taguchi design was able to achieve desired surface roughness. The optimal drilling performance for the surface roughness was obtained at 0.16 mm/rev feed rate, 260 rev/min spindle speed, 130° drill point angle, carbide drill type, and as-received heat treatment settings.

Similar content being viewed by others

References

Christman T, Suresh S (1988) Microstructural development in an aluminum alloy–SiC whisker composite. Acta Mater 36(7):1691–1704

Palanikumar K, Shanmugam K, Davim JP (2010) Analysis and optimisation of cutting parameters for surface roughness in machining Al/SiC particulate composites by PCD tool. Int J Mater Prod Technol 37(1/2):117–128

Iosub A, Axinte E, Negoescu F (2010) A Study about micro-drilling by electrical discharge method of an Al/SiC hybrid composite. Int J Acad Res 2(3):6–12

Basavarajappa S, Chandramohan G, Davim JP (2008) Some studies on drilling of hybrid metal matrix composites based on Taguchi techniques. J Mater Process Technol 196(1–3):332–338

Mubaraki B, Bandyopandhyay S, Fowle R, Mathew P (1995) Drilling studies of an Al2O3-Al metal matrix composite: part I, drill wear characteristics. J Mater Sci 30:6273–6280

El-Gallab M, Sklad M (1998) Machining of Al/SiC particulate metal–matrix composites part II: work piece surface integrity. J Mater Process Technol 83:277–285

Zhang JZ, Chen JC (2009) Surface roughness optimization in a drilling operation using the Taguchi design method. Mater Manuf Process 24:459–467

Brown CA, Surappa MK (1988) The machinability of a cast aluminum alloy–graphitic particle composite. Mater Sci Eng A 102:31–37

Konig W, Grass P (1989) Quality definition and assessment in drilling of fibre reinforced thermosets. CIRP Ann 38(1):119–124

Darwish SM, Niazi A, Ghaneya A (1992) Phase stability of duralumin machined with bonded and brazed carbide tools. Int J Mach Tools Manuf 32(4):593–600

Monaghan J, O’Reily P (1992) Machinability of an alloy/silicon carbide metal matrix composite. J Process Adv Mater 2:37–46

Monaghan J, O’Reilly P (1992) The drilling of an Al/SiC metal–matrix composite. J Mater Process Technol 33:469–480

Wern CW, Ramulu M, Colligan K (1993) A study of the surface texture of composite drilled holes. J Mater Process Technol 37:373–389

Oden M, Ericsson T (1996) Near surface deformation in alumina–silicon carbide whisker composite due to surface machining. J Am Ceram Soc 79:2134–2140

Songmene AV, Balazinzki M (1999) Machinability of graphitic metal matrix composites as a function of reinforcing particles. CIRP 48(1):77–80

Barnes S, Pashby IR, Hashim AB (1999) Effect of heat treatment on the drilling performance of aluminium/SiC MMC. Appl Compos Mater 6(2):121–138

Davim JP, Antonio CAC (2001) Optimal drilling of particulate metal matrix composites based on experimental and numerical procedures. Int J Mach Tools Manuf 41:21–31

Ramulu M, Kim D, Kao H (2003) Experimental study of PCD tool performance in drilling (Al2O3)/6061 metal matrix composites. SME Technical Paper. MR03-171:1–7

Davim JP (2003) Study of drilling metal–matrix composites based on the Taguchi techniques. J Mater Process Technol 132:250–254

Tosun G, Muratoglu M (2004) The drilling of Al/SiCp metal–matrix composites. Part II: workpiece surface integrity. Compos Sci Technol 64:1413–1418

Tosun N, Ozler L (2004) Optimization for hot turning operations with multiple performance characteristics. Int J Adv Manuf Technol 23:777–778

Sahin Y (2005) Optimization of testing parameters on the wear behaviour of metal matrix composites based on the Taguchi method. Mat Sci Eng A 408:1–8

Tosun N (2006) Determination of optimum parameters for multiperformance characteristics in drilling by using grey relational analysis. Int J Adv Manuf Technol 28:450–455

Jadoun RS, Kumar P, Mishra BK, Mehta RCS (2006) Optimization of process parameters for ultrasonic drilling of advanced engineering ceramics using the Taguchi approach. Eng Optim 38(7):771–787

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tosun, G. Statistical analysis of process parameters in drilling of AL/SICP metal matrix composite. Int J Adv Manuf Technol 55, 477–485 (2011). https://doi.org/10.1007/s00170-010-3103-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3103-7