Abstract

In this work, countersinking which is the manufacturing operation used to enlarge the side of an existing hole is studied. A finite element model is built in order to get the normalized dimensions of the countersink. The obtained countersink allows to the head of screws or rivets to sit flush with the surface with the surrounding material. A case study is detailed in order to show the effect of the pertinent parameters. The procedure is summarized by the construction of a single diagram in which the coupled effects of the different parameters are shown. A fully automatic procedure can be built in the light of this analysis.

Similar content being viewed by others

References

Ray MS, Matthew IR, Frame JW (1998) Metallic fragments on the surface of miniplates and screws before insertion. British J Oral Maxill Surg 37:14–18

Urban MR (2003) Analysis of the fatigue life of riveted sheet metal helicopter airframe joints. Int J Fatigue 25:1013–1026

Park CY, Grandt Jr AF, Suh JJ (2006) Stress intensity factors for surface cracks at countersunk holes. Eng Fract Mech 73:1878–1898

Sohel Rana M, Makabe C, Fujiwara G (2009) The effect of hole shape on the extent of fatigue life improvement by cold expansions. Eng Fail Anal 16:2081–2090

Sathiya S, DVTG Naarayan et al (2009) Implication of unequal rivet load distribution in the failures and damage tolerant design of metal and composite civil aircraft riveted lap joints. Eng Fail Anal 16:2255–2273

Park CJ, Grandt Jr, AF (2007) Effect of load transfer on the cracking behavior at a countersunk fastener hole. Int J Fatigue 29:146–157

Blanchot V, Daidie A (2006) Riveted assembly modelling: study and numerical characterisation of a riveting process. J Mater Process Technol 180:201–209

Krichen A, Saï K, Bouzid W (2008) Finite element modelling of countersinking process. Int J Mat Prod Tech 33:376–386

NF EN 20273 (1992) Elements de fixation. Trou de passage par vis. 06-1992. Lavoisier (in French)

Zébulon (2008) User’s manual. Ecole Supérieure des Mines de Paris, France

Geuzaine C, Remacle JF (2005) reference manual for Gmsh 1.60-an automatic 3D finite element generator. GNU Project

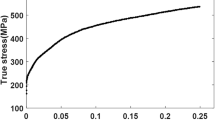

Lee EH (1969) Elastic–plastic deformation at finite strains. J Appl Mech 36:1–6

Chaboche JL (1975) Viscoplastic constitutive equations for the description of cyclic and anisotropic behavior of metals. Bull Acad Pol Sci 25:33–42

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jallouli, I., Krichen, A., Bougharriou, A. et al. Finite element analysis of countersinking process. Int J Adv Manuf Technol 55, 641–648 (2011). https://doi.org/10.1007/s00170-010-3090-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3090-8