Abstract

Mixed-model production is the practice of assembling different and distinct models in a line without changeovers with responding to sudden demand changes for a variety of models. In this paper, we specify sequence of models to minimize conveyer stoppages. We assume that our lines are fixed and we cannot change the balance of the lines. When the condition of lines like setup cost and demand of each model change, it is important to specify the sequence for minimizing the conveyer stoppages without balancing the line again because the main lines are fixed. We consider three objective functions simultaneously: minimizing the variation in the actual and required production capacity of the line and minimizing the objectives which increase the chance of conveyer stoppage, including: (a) minimizing the total setup time, (b) minimizing the total production variation cost, and (c) minimizing the total utility work cost. Because of conflicting objectives, we propose the fuzzy goal programming-based approach to solve the model. Finally, we present an estimator for nearness of conveyer stoppages and study about affecting of sub-lines and changing the conveyer velocity in a station for reducing stoppages.

Similar content being viewed by others

References

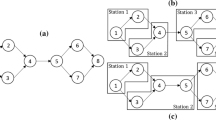

Mirzapour Al-e-Hashem SMJ, Aryanezhad MB (2009) An efficient method to solve a mixed-model assembly line sequencing problem considering a sub-line. World Appl Sci J 6(2):168–181

Xiaobo Z, Zhou Z, Asres A (1999) A note on Toyota’s goal of sequencing mixed models on an assembly line. Comput Ind Eng 36:57–65

Yano CA, Rachamadugu R (1991) Sequencing to minimize work overload in assembly lines with product options. Manage Sci 37:572–586

Bautista J, Companys R, Corominas A (1996) Heuristics and exact algorithms for solving the Monden problem. Eur J Opl Res 88:101–113

Leu Y, Matheson LA, Rees LP (1996) Sequencing mixed-model assembly lines with genetic algorithms. Comput Ind Eng 30:1027–1036

Miltenburg J, Sinnamon G (1989) Scheduling mixed-model multi-level just-in-time production systems. Int J Prod Res 27:487–509

Boysen N, Fliedner M, Scholl A (2007) Sequencing mixed-model assembly lines: survey, classification and model critique. Eur J Oper Res 192(2):349–373

Karkmazel T, Meral S (2003) Theory and methodology. Bicriteria sequencing method for the mixed-model assembly line in just-in-time production systems. Eur J Oper Res 131:188–207

Scholl A, Klein R, Domschke W (1998) Pattern based vocabulary building for effectively sequencing mixed-model assembly lines. Journal of Heuristics 4:359–381

Mahdavi I, Javadi B, Sahebjamnia N, Mahdavi-Amiri N (2009) A two-phase linear programming methodology for fuzzy multi-objective mixed-model assembly line problem. Int J Adv Manuf Technol 44:1010–1023

Hsiao FH, Xu SD, Lin CY, Tsai ZR (2008) Robustness design of fuzzy control for nonlinear multiple time-delay large-scale systems via neural-network-based approach. IEEE Trans Syst Man Cybern B Cybern 38(1):244–251

Chen CY, Hsu JRC, Chen CW (2005) Fuzzy logic derivation of neural network models with time delays in subsystems. Int J Artif Intell Tools 14(6):967–974

Tamura T, Long H, Ohno K (1999) A sequencing problem to level part usage rates and work loads for a mixed-model assembly line with a bypass subline. Int J Prod Econ 60–61:557–564

Mansouri SA (2005) A multi-objective genetic algorithm for mixed-model sequencing on JIT assembly lines. Eur J Oper Res 167:696–716

Miltenburg J, Sinnamon G (1995) Revisiting the mixed-model multi-level just-in-time scheduling problem. Int J Prod Res 33:2049–2052

Monden Y (1993) Toyota production system, 2nd edn. Institute of Industrial Engineers, Norcross, GA

Morabito MA, Kraus ME (1995) A note on “Scheduling mixed-model multi-level just-in-time production systems”. Int J Prod Res 33:2061–2063

Steiner G, Yeomans JS (1996) Optimal level schedules in mixed-model, multi-level JIT assembly systems with pegging. Eur J Opl Res 95:38–52

Sumichrast RT, Clayton ER (1996) Evaluating sequences for paced, mixed-model assembly lines with JIT component fabrication. Int J Prod Res 34:3125–3143

Sumichrast RT, Russell RS (1990) Evaluating mixed-model assembly line sequencing heuristics for just-in-time production systems. J Oper Manage 9:371–389

Sumichrast RT, Russell RS, Taylor BW (1992) A comparative analysis of sequencing procedures for mixed-model assembly lines in a just-in-time production system. Int J Prod Res 30:199–214

Kubiak W (1993) Minimizing variation of production rates in just-in-time systems: a survey. Eur J Opl Res 66:259–271

Xiaobo Z, Ohno K (1994) A sequencing problem for a mixed-model assembly line in a JIT production system. Comput Ind Eng 27:71–74

Chen CY, Lin JW, Lee WI, Chen CW (2010) Fuzzy control for an oceanic structure: a case study in time-delay TLP system. J Vib Control 16:147. doi:10.1177/1077546309339424

Ding FY, Zhu J, Sun H (2006) Comparing two weighted approaches for sequencing mixed-model assembly lines with multiple objectives. Int J Prod Econ 102:108–131

Bautista J, Cano J (2008) Minimizing work overload in mixed-model assembly lines. Int J Prod Econ 112:177–191

Kim S, Jeong B (2007) Product sequencing problem in mixed-model assembly line to minimize unfinished works. Comput Ind Eng 53:206–214

Yoo JK, Shimizu Y, Hinoo R (2004) A sequencing problem for mixed model assembly lines with aid of relief-man. JSME Int J 48(1):15–20

Okamura K, Yamshina H (1979) A heuristic algorithm for the assembly line model-mix sequencing problem to minimize the risk of stopping the conveyor. Int J Prod Res 17:233–247

Bard JF, Dar-El EM, Shtub A (1992) An analytic framework for sequencing mixed-model assembly lines. Int J Prod Res 30:35–48

Hyun CJ, Kim Y, Kim YK (1998) A genetic algorithm for multiple objective sequencing problems in mixed model assembly lines. Comput Oper Res 25(7–8):675–690

Ponnambalama SG, Aravindanb P, Subba RM (2003) Genetic algorithms for sequencing problems in mixed model assembly lines. Comput Ind Eng 45:669–690

Miltenburg J, Stenier G, Yeomans S (1990) A dynamic programming algorithm for scheduling mixed model, just in time production system. Math Comput Model 13(3):57–66

Tamiz M, Jones D, Romero C (1998) Goal programming for decision making: an overview of the current state-of-the-art. Eur J Oper Res 111:569–581

Javadi B, Rahimi-Vahed A, Rabbani M, Dangchi M (2008) Solving a multi-objective mixed-model assembly line sequencing problem by a fuzzy goal programming approach. Int J Adv Manuf Technol 39:975–982

Charnes A, Cooper WW (1961) Management models and industrial applications of linear programming, vol 4(3). Wiley/Society for Industrial and Applied Mathematics, New York, pp 267–268

Bellman RE, Zadeh LA (1970) Decision making in a fuzzy environment. Manage Sci 17:141–164

Zimmermann HJ (1976) Description and optimization of fuzzy systems. Int J Gen Syst 2:209–215

Zimmermann HJ (1978) Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst 1:45–56

Kim JS, Whang KS (1998) Theory and methodology a tolerance approach to the fuzzy goal programming problems with unbalanced triangular membership function. Eur J Oper Res 107:614–624

Martel JM, Aouni BA (1998) Diverse imprecise goal programming model formulations. J Glob Optim 12:127–138

Ramik J (2000) Fuzzy goals and fuzzy alternatives in goal programming problems. Fuzzy Sets Syst 111:81–86

Chen LH, Tsai FC (2001) Theory and methodology fuzzy goal programming with different importance and priorities. Eur J Oper Res 133:548–556

Iskander MG (2004) A fuzzy weighted additive approach for stochastic fuzzy goal programming. Appl Math Comput 154:543–553

Chun LC (2004) A weighted max–min model for fuzzy goal programming. Fuzzy Sets Syst 142:407–420

Saad OM (2005) An iterative goal programming approach for solving fuzzy multi objective integer linear programming problems. Appl Math Comput 170:216–225

Iskander MG (2006) Exponential membership function in stochastic fuzzy goal programming. Appl Math Comput 173:782–791

Hu CF, Teng CJ, Li SY (2007) Continuous optimization a fuzzy goal programming approach to multi-objective optimization problem with priorities. Eur J Oper Res 176:1319–1333

Akoz O, Petrovic D (2007) A fuzzy goal programming method with imprecise goal hierarchy. Eur J Oper Res 181:1427–1433

Yaghoobi MA, Tamiz M (2007) A method for solving fuzzy goal programming problems based on minimax approach. Eur J Oper Res 177:1580–1590

Chein TL, Chen CC, Haung YC, Lin WJ (2008) Stability and almost disturbance decoupling analysis of nonlinear system subject to feedback linearization and feed forward neural network controller. IEEE Trans Neural Netw 19:1220. doi:10.1109/TNN.2008.2000207

Chen CW, Yeh K, Liu KFR (2009) Adaptive fuzzy sliding mode control for seismically excited bridges with lead rubber bearing isolation. Int J Uncertain Fuzziness Knowl Based Syst 17:705. doi:10.1142/S0218488509006224

Arora SR, Gupta R (2009) Continuous optimization interactive fuzzy goal programming approach for bilevel programming problem. Eur J Oper Res 194:368–376

Yager RR (1977) Multiple objective decision-making using fuzzy sets. Int J Man Mach Stud 9:375–382

Bard JF, Shtub A, Joshi SB (1994) Sequencing mixed-model assembly lines to level parts usage and minimize the length. Int J Prod Res 32:2431–2454

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rabbani, M., Radmehr, F. & Manavizadeh, N. Considering the conveyer stoppages in sequencing mixed-model assembly lines by a new fuzzy programming approach. Int J Adv Manuf Technol 54, 775–788 (2011). https://doi.org/10.1007/s00170-010-2968-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2968-9