Abstract

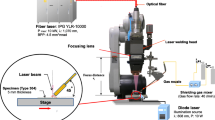

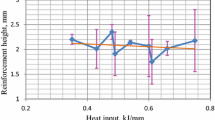

A planned and orderly analysis of the microstructures and bead profiles of AISI 904 L super austenitic stainless steel bead-on-plate welds was accomplished by coupling up diffusion cooled slab 3.5 kW CO2 laser with two dissimilar shielding gaseous mixture namely 100% nitrogen (N) and 50% argon + 50% nitrogen (A + N). AISI 904 L Super Austenitic Stainless Steel (SASS) incorporates higher levels of Mo, Cr, Ni, N, and Mn under normal conditions. In heating applications, it offers a superior corrosion resistance at moderate and higher temperatures. The microstructure of SASS is exhaustively austenitic in nature, when subjected to a solution-quenched state. The objective of this study is to determine the phenomenon that follows the action of two shielding gas mixtures on microstructural and bead profiles of laser-welded 904 L SASS. The weld bead profile of laser welding depends on various parameters such as beam power; travel speed, and focal position of the laser spot, and these factors have to be chosen in an appropriate manner to obtain the desired output. The cross-sectioned area of the bead profiles like bead width and depth of penetration is measured using an optical microscope. Two different shielding gas mixtures were used to examine the microstructural changes in the weld region. Besides, the variation in the hardness of the weld region was analyzed through the Vickers hardness tester.

Similar content being viewed by others

References

Mackwood AP, Crafer RC (2005) Thermal modeling of laser welding and related processes: a literature review. Opt Laser Technol 37:99–115

Kaiser E, Schafer P (2005) Pulse shaping optimizes the quality of seam and spot welds. In: Lasers in manufacturing, proceeding of the third international WLT—conference on lasers in manufacturing. pp. 695–670

Sun Z, Kuo M (1998) Bridging the joint gap with wire feed laser welding. J Mater Process Technol 87:213–222

Br P, Balciuniene M (2005) Peculiarities of laser welding of metals. Lithuaniam J Phys 45(1):59–69

Metals Handbook (1993) Welding, brazing and soldering, ASM, (9a ed.); vol. 6, ISBN 0-87170-007

Kane SF (1999) Welding consumable development for a cryogenic application. Welding J 8:292 s–300 s

Dawes C (1992) Laser welding. Abington Publishing, New York

Molian PA (1985) Solidification behavior of laser welded stainless steel. J Mater Sci Lett 4:281–283

Deepashri D, Nage RVS, Raman R (2006) Effect of nitrogen addition on the microstructure and mechanical behavior on 317 L and 904 L austenitic stainless steel welds. J Mater Sci 41:2097–2112

Bonollo F, Tiziani A, Tovo T, Volpone LM (2004) Super austenitic stainless steel: the microstructure and fatigue strength a welded joints. Weld Int 18(1):24–30

Heino S, Knutson-wedel EM, Karlsson B (1999) Precipitation behavior in heat affected zone of welded super austenitic stainless steel. J Mater Sci Technol 15(1):101–108

Suutala N (1983) Effect of solidification conditions on the solidification mode in austenitic stainless steels. Metall Mater Trans A 14:191–197

David SA, Vitek JM (1981) Laser in metallurgy. Conference proceedings of the metallurgical society of AIME. pp. 147–150

Arata Y, Matsuda F, Katayama S (1976) Fundamental investigation on solidification behaviour of fully austenitic and duplex microstructure and effect of ferrite on micro segregation. Trans Jpn Weld Res Inst 5(2):35–51

Benjounis KY, Olabi AG, Hasmi MSJ (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mater Process Technol 164–165:978–985

Vilar R, Miranda RM (1988) Laser welding of thin sheet of AISI 301 stainless steel. SPIE 952. Laser Technologies in Industry, Porto, pp 719–725

Zambon A, Ferro P, Bonollo F (2006) Microstructural, compositional and residual stress evaluation of CO2 laser welded super austenitic AISI 904 L stainless steel. Mater Sci Eng A 424:117–127

Staffan Hertzman, Pettersson Rjargelius, Roland Blom, Esa Kivineva, Jan Eriksson (1996) Influence of shielding gas composition and welding parameters on the N-content and corrosion properties of welds in N-alloyed stainless steel grades. ISIJ Int 36(7):968–976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sathiya, P., Abdul Jaleel, M.Y. Influence of shielding gas mixtures on bead profile and microstructural characteristics of super austenitic stainless steel weldments by laser welding. Int J Adv Manuf Technol 54, 525–535 (2011). https://doi.org/10.1007/s00170-010-2967-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2967-x