Abstract

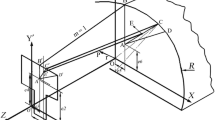

The geometry of die profile plays a major role in reducing the extrusion pressure and ensuring the smooth flow of material. In general, the extrusion process is mostly affected by billet geometry, die geometry, and interface frictional force at the die billet geometry. In the present investigation, an analysis using three-dimensional upper bound method using fifth-order die profile function has been carried out for extrusion of square sections from square billet. The extrusion pressure and optimum die length have been computed by multivariable optimization technique. The present die shape profile is found to be superior to many other profiles. The results obtained will help in design of optimum die profile and investigation of its performance.

Similar content being viewed by others

References

Gunasekara JS, Hoshino S (1985) Analysis of extrusion of polygonal sections through streamlined dies. Trans ASME J Eng Ind 107:229–233

Gunasekara JS, Hoshino S (1982) Analysis of extrusion of drawing of polygonal sections through straightly converging dies. Trans ASME J Eng Ind 104:38–44

Juneja BL, Prakash R (1975) An analysis for drawing and extrusion of polygonal sections. Int J Mach Tool Des Res 15:1–13

Nagpal V, Altan T (1975) Analysis of the three dimension metal flow in extrusion of shapes with the use of dual stream functions. In: Proceedings of the 3rd North American metal working research conference, Pittsburgh, pp 26–40

Yang DY, Lee CH (1978) Analysis of three-dimensional extrusion of sections through curved dies by conformal transformation. Int J Mech Sci 20:541–552

Yang DY, Kum MU, Lee CH (1979) A new approach for generalized three-dimensional extrusion of sections from round billets by conformal transformation. In: JUTAM Symposium on metal forming plasticity, Germany, 1979, pp 204–211

Maity KP, Kar PK, Das NS (1996) A class of upper-bound solutions for the extrusion of square shapes from square billets through curved dies. Int J Mater Process Technol 62:185–190

Sahoo SK, Kar PK, Singh KC (1999) A numerical application of the upper-bound technique for round-to-hexagon extrusion through linearly converging dies. Int J Mater Process Technol 91:105–110

Wifi AS, Shatla MN, Hamid-Abdel A (1998) An optimum curved die profile for the hot forward rod extrusion process. Int J Mater Process Technol 73:97–111

Ponalagusamy R, Narayanasamy R, Srinivasan P (2005) Design & Development of streamlined extrusion dies a Bezier curve approach. Int J Mater Process Technol 161:375–380

Ponalagusamy R, Narayanasamy R, Venkatesan R, Senthilkumar S (2008) Computer aided metal flow investigation in streamlined extrusion dies. Int J Mater Des 29:1228–1239

Narayanasamy R, Ponalagusamy R, Venkatesan R, Srinivasan P (2006) An upper bound solution to extrusion of circular billet to circular shape through cosine dies. Int J Mater Des 27:411–415

Kuester JL, Mize JH (1973) Optimization techniques with Fortran. Mcgraw-Hill Book Company, New York

Yih CS (1957) Stream functions in three-dimensional flow. La Haulle Blanche 12:445

Maity KP (1988) Analysis of three-dimensional extrusion through curved dies, M. Tech Thesis, R.E.C. Rourkela, Sambalpur University

Altan T, Oh Soo-lk, Gegel HL. Metal forming fundamentals and applications. Copyright by the American Society for Metals, Carnes Publication Services, Inc, USA, pp 48–52; 85–87

Patra LN, Sahoo SK. R09177-upset forging of sectional blocks: a three-dimensional analysis, published In: Proceedings of the 2nd International Conference on Recent Advances in Material Processing Technology, organized by the Department of Mechanical Engineering, NIT, Rourkela, Orissa, pp 394–398

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rout, A.K., Maity, K. Numerical and experimental study on the three-dimensional extrusion of square section from square billet through a polynomial shaped curved die. Int J Adv Manuf Technol 54, 495–506 (2011). https://doi.org/10.1007/s00170-010-2954-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2954-2