Abstract

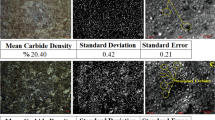

The cryogenic treatment of tool steels has transformed over centuries from black art to science, but the metallurgical principles responsible for increase in wear resistance, tensile strength, toughness, and stability are still disputed. Metallurgists comprehend how tool steels respond to cryogenic treatment, but they also understand that for many years, the cryogenic treatment of tool steels had the reputation of being a quick fix for poor heat treatment practice. During the cryogenic treatment of tool steels, the process modifies the carbon present in the tool steels. However, cryogenic treatment has not been widely adopted by the cutting tools industry due to lack of understanding of the fundamental metallurgical mechanisms and due to the wide variation in reported research findings. In the present paper, an attempt has been made to review the literature on metallurgical changes that occurred during the cryogenic treatment of tool steels to benefit the cutting tools industry. The prominent reasons found to be responsible for improving the mechanical properties of tool steels are transformation of retained austenite to martensite and precipitation of fine carbides.

Similar content being viewed by others

References

Wilkins C (1999) Cryogenic processing; the big chill. EDM Today 36–44 (May/June)

Popandopulo N, Zhukova LT (1980) Transformation in high speed steels during cold treatment. Met Sci Heat Treat 22(10):708–710

Carlson EA (1990) Cold treating and cryogenic treatment of steel in ASM handbook, vol. 4. Heat treating, 10th edn. ASM International, Metals Park, OH, pp 203–206

Barron RF (1974) Do treatments at temperatures below −120°F help … Here are some research findings that indicate they do. Heat Treat 5:14

Cohen P, Kamody D (1998) Cryogenics goes deeper. Cutt Tool Eng l50(7):46–50

Preciado M, Bravo PM, Alegre JM (2006) Effect of low temperature tempering prior cryogenic treatment on carburized steels. J Mater Process Technol 176(1–3):41–44

Wilson RA (1971) Industry warms up to supercold. Iron Age 5556 (Aug)

Barron RF (1973) Effect of cryogenic treatment on lathe tool wear. In: Pentzer WT et al (eds) Progress in refrigeration science and technology. AVI, Westport, pp 529–534

Barron RK (1974) Cryogenic treatment produces cost savings for slitter knives. Tappi J 57(5):137

Barron RF (1982) Cryogenic treatments on metals to improve wear resistance. Cryogenics 22:409–414

Meng F, Tagashira K, Azuma R, Sohma H (1994) Role of etacarbide precipitations in the wear resistance improvements of Fe–12Cr–Mo–V–1.4C tool steel by cryogenic treatment. ISIJ Int 34:205–210

Collins DN (1996) Deep cryogenic treatment of tool steels—a review. Heat Treat Met 23(2):40–42

Collins DN, Dormer J (1997) Deep cryogenic treatment of a D2 cold-worked tool steel. Heat Treat Met 3:71–74

Kamody DJ (1999) Cryogenics process update. Adv Mater Process 155(6):H67–H69

Molinari A, Pellizzari M, Gialanella S, Straffelini G, Stiasny KH (2001) Effect of deep cryogenic treatment on the mechanical properties of tool steels. J Mater Process Technol 118(1–3):350–355

Mohan Lal D, Renganarayanan S, Kalanidhi A (2001) Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 41(3):149–155

Reitz W, Pendray J (2001) Cryoprocessing of materials: a review of current status. Mater Manuf Process 16(6):829–840

Bensely A, Prabhakaran A, Mohan Lal D, Nagarajan G (2005) Enhancing the wear resistance of case carburized steel (En 353) by cryogenic treatment. Cryogenics 45(12):747–754

Yang HS, Wang J, Shen BL, Liu HH, Gao SJ, Huang SJ (2006) Effect of cryogenic treatment on the matrix structure and abrasion resistance of white cast iron subjected to destabilization treatment. Wear 26:1150–1154

Leskovsek V, Kalin M, Vizintin J (2006) Influence of deep cryogenic treatment on wear resistance of vacuum heat-treated HSS. Vacuum 80:507–518

Das D, Dutta AK, Toppo V, Ray KK (2007) Effect of deep cryogenic treatment on the carbide precipitation and tribological behavior of D2 steel. Mater Manuf Process 22(4):474–480

Das D, Dutta AK, Ray KK (2008) On the enhancement of wear resistance of tool steels by cryogenic treatment. Phil Mag Lett 88:801–811

Das D, Dutta AK, Ray KK (2009) Influence of varied cryotreatment on the wear behavior of AISI D2 steel. Wear 266(1–2):297–309

Das D, Dutta AK, Ray KK (2009) On the refinement of carbide precipitates by cryotreatment in AISI D2 steel. Philos Mag 89(1):55–76

Das D, Dutta AK, Ray KK (2009) Optimization of the duration of cryogenic processing to maximize wear resistance of AISI D2 steel. Cryogenics 49:176–184

Das D, Ray KK, Dutta AK (2009) Influence of temperature of sub-zero treatments on the wear behaviour of die steel. Wear 267:1361–1370

Das D, Dutta AK, Ray KK (2009) Correlation of microstructure with wear behaviour of deep cryogenically treated AISI D2 steel. Wear 267:1371–1380

Paulin P (1993) Frozen gears. Gear Technol 10:26–29

Blankinship S (2001) Ultra-cold could help freeze plant repairs. Power Eng 105:13 and 16

Stratton PF (2007) Optimising nano-carbide precipitation in tool steels. Mater Sci Eng A 449–451:809–812

Gill SS, Singh H, Singh R, Singh J (2010) Cryoprocessing of cutting tool materials—a review. Int J Adv Manuf Tech 48(1–4):175–192

Gulyaev AP (1937) Improved methods of heat treating high speed steels to improve the cutting properties. Metallurgy 12:65

Moore K, Collins DN (1993) Cryogenic treatment of three heat treated tool steels. Key Eng Mater 86&87:47–54

Dymchenko VV, Safronova VN (1993) Refrigeration treatment of quenched roll steel. Tyazhel Mashinostr 9:29–32

Soundararajan V, Alagurmurthi N, Palaniradja K (2004) On the enhancement of wear resistance of hardened carbon tool steel (AISI 1095) with cryogenic quenching. Trans Mater Heat Treat 25(5):531–535

Babu PS, Rajendran P, Rao KN (2005) Cryogenic treatment of M1, EN19, and H13 tool steels to improve wear resistance. J Inst Eng India MM 86:64–66

Da Silva FJ, Franco SD, Machado AR, Ezugwu EO, Souza AM Jr (2006) Performance of cryogenically treated HSS tools. Wear 261(5–6):674–685

Zhirafar S, Rezaeian A, Pugh M (2007) Effect of cryogenic treatment on the mechanical properties of 4340 steel. J Mater Process Technol 186(1–3):298–303

Li S, Xie Y, Wu X (2010) Hardness and toughness investigations of deep cryogenic treated cold work die steel. Cryogenics 50(2):89–92

Biao G, Jiyuan C (1997) Property improvement and microstructure transformation of high-speed steel due to deep cryogenic treatment. J Dalian Univ Tech 37(3):285–289

Satish Kumar M, Mohan Lal D, Renganarayanan S, Kalanidhi A (2001) An experimental investigation on the mechanism of wear resistance improvement in cryotreated tool steels. Indian J Eng Mater Sci 8(4):198–204

Yugandhar T, Krishnan PK (2002) Cryogenic treatment and its effects on tool steel. Proceedings of 6th International Tooling Conference, Karlstad University, September, pp 671–684

Zurecki Z (2006) Cryogenic quenching of steel revisited. ASM proceedings: heat treating. ASM, Pennsylvania, pp 106–113

Bulancea V, Condurache D, Gheorghiu DA (2008) Frozen high alloyed steels. Annals of the University of Craiova, Electrical Engineering Series, No. 32, 2008; ISSN 1842-4805, pp 342–345

Dhokey NB, Nirbhavne S (2009) Dry sliding wear of cryotreated multiple tempered D-3 tool steel. J Mater Process Technol 209(3):1484–1490

Firouzdor V, Nejati E, Khomamizadeh F (2008) Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J Mater Process Technol 206:467–472

Yun D, Xiaoping L, Hongshen X (1998) Deep cryogenic treatment of high-speed steel and its mechanism. Heat Treat Met 3:55–59

Pellizzari M, Molinari A (2002) Deep cryogenic treatment of cold work tool steel. Proceedings of the 6th International Tooling Conference, Karlstad University, September, pp 657– 669

Leskovsˇek V, Ule B (2002) Influence of deep cryogenic treatment on vacuum heat-treated high-speed steel. Heat Treat Met 29(3):72–76

Huang JY, Zhu YT, Liao XZ, Beyerlein IJ, Bourke MA, Mitchell TE (2003) Microstructure of cryogenic treated M2 tool steel. Mater Sci Eng A 339:241–244

Kalin M, Leskovsek V, Vizintin J (2006) Wear behavior of deep cryogenic treated high speed steel at different loads. Mater Manuf Process 21:741–746

Bensely A, Venkatesh S, Mohan Lal D, Nagarajan G, Rajadurai A, Junik K (2008) Effect of cryogenic treatment on distribution of residual stress in case carburized En 353 steel. Mater Sci Eng A 479(1):229–235

Vimal AJ, Bensley A, Lal DM, Srinivasan K (2008) Deep cryogenic treatment improves wear resistance of En 31 steel. Mater Manuf Process 23(4):369–376

Avner SH (1982) Introduction to physical metallurgy. McGraw-Hill, New York

Roberts GA, Cary RA (1980) Tool steels, 4th edn. ASM, Materials Park, OH

Herring DH (2005) Cold and cryogenic treatment of steel. Heat Treating Progress 5(7):50

Herring DH (2005) Cold and cryogenic treatments. Ind Heat 72(5):16–18

Alexandru G, Ailincai C, Baciu (1990) Influence of cryogenic treatments on life of alloyed high speed steels. Mém Étud Sci Rev Métall 4:283–388

RC Weast (1981–1982) Handbook of chemistry and physics, 62nd edn. CRC, pp D161–D162

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gill, S.S., Singh, J., Singh, R. et al. Metallurgical principles of cryogenically treated tool steels—a review on the current state of science. Int J Adv Manuf Technol 54, 59–82 (2011). https://doi.org/10.1007/s00170-010-2935-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2935-5