Abstract

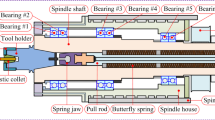

The cutting performance relates to the dynamic properties of the whole system of the tool, spindle, and machine tool frame. The impact of the machine frame properties on the dynamic properties at the tool end point is studied both experimentally and using a coupled simulation model. Coupled model of the whole mechanical system is created as a system joining the spindle detailed model and machine frame FE model. Shift in the spindle and tool system dynamic properties, related to the machine frame properties, is proved using the coupled model. Experimental verification of the FRF evaluated at the tool is extended also by cutting tests. Good match of the simulated dynamic properties of the whole system with the real behavior is found.

Similar content being viewed by others

References

Albertelli P, Leonesio M, Bianchi G (2007) Spindle—machine tool interaction and cutting process stability. AITeM Conference, Montecatini Terme, Italy

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642

Arnold RN (1946) The mechanism of tool vibration in the cutting of steel. Proc Inst Mech Eng Lond 154:261–276

Budak E, Altintas Y (1998) Analytical prediction of chatter stability conditions for multi-degree of freedom systems in milling, Part I: modeling, Part II: applications. J Dyn Syst Meas Control 120:22–36

Cao Y, Altintas Y (2007) Modeling of spindle-bearing and machine tool systems for virtual simulation of milling operations. Int J Mach Tools Manuf 47(9):1342–1350

Hanna NH, Tobias SA (1974) A theory of nonlinear regenerative chatter. J Eng Ind 96:247–255

Harris TA (1991) Rolling bearings analysis, 3rd edn. Wiley, New York

Hoffman F, Brecher C (2005) Simulation von Verfahroperationen. Werkstattstechnik Online 95(7/8):506–512

Holkup T, Cao H, Kolar P, Altintas Y, Zeleny J (2010) Thermo-mechanical model of spindles. CIRP Ann 59(1):365–368

Jones AB (1960) A general theory for elastically constrained ball and radial roller bearings under arbitrary load and speed conditions. J Trans ASME Basic Eng 82:309–320

Kashirin AJ (1944) Research of vibrations in metal cutting. Izdatelstvo AN SSSR, Moscow, In Russian

Koenigsberger F, Tlusty J (1967) Machine tool structures: stability against chatter, vol. I., Pergamon

Kolar P, Holkup T (2007) Modeling of a machine tools spindle using a hybrid model. Proc. of 3 rd Int. Conf.—Virtual Design and Automation. Paper No. S05_06_01_kolar

Kreis M (2008) Zum Eigenverhalten von Motorspindeln unter Betriebsbedingungen: Einflüsse und Konsequenzen für die Prozessstabilität. Ph.D. thesis, TU Darmstadt

Lehner M, Eberhard P (2006) Modelreduktion in elastischen Mehrkörpersystemen. Automatisierungstechnik 54(4):170–177

Li H, Shin YC (2003) Analysis of bearing configuration effects on high speed spindles using an integrated dynamic thermo-mechanical spindle model. Int J Mach Tools Manuf 44:347–364

Li H, Shin YC (2004) Integrated dynamic thermo-mechanical modeling of high speed spindles, part 1: model development, part 2: solution procedure and validation. Trans ASME, J Manuf Sci Eng 126(148–158):159–168

Lin CW, Tu JF, Kamman J (2003) An integrated thermo-mechanical-dynamical model to characterize motorized machine tool spindles during very high speed rotation. Int J Mach Tools Manuf 43:1035–1050

Maj R, Bianchi G (2005) Mechatronic analysis of machine tools. 9th SAMTECH Users Conference

Merrit H (1965) Theory of self-excited machine tool chatter. J Eng Ind 87(4):447–454

Nelson HD, McVaugh JM (1976) The dynamics of rotor-bearing systems using finite elements. J Eng Ind 93(2):593–600

Nelson HD (1980) A finite rotating shaft element using Timoshenko beam theory. J Mech Des 102:793–803

Park SS, Altintas Y, Movahhedy M (2003) Receptance coupling for end mills. Int J Mach Tools Manuf 43:889–896

Rantatalo M, Aidanpää JA, Göransson B, Normand P (2007) Milling machine spindle analysis using FEM and non-contact spindle excitation and response measurement. Int J Mach Tools Manuf 47(7–8):1034–1045

Schmitz TL (2000) Predicting high-speed machining dynamics by substructure analysis. CIRP Ann 49(1):303–308

Schmitz TL, Davies MA, Kennedy MD (2001) Tool point frequency response prediction for high-speed machining by RCSA. Trans ASME, J Manuf Sci Eng 123(4):700–707

Schmitz TL, Duncan GS (2005) Three-component receptance coupling substructure analysis for tool point dynamics prediction. Trans ASME, J Manuf Sci Eng 127(4):781–790

Siedl D (2007) Flexible Mehrkörpersimulation im Entwicklungsprozess von Werkzeugmaschinen. Seminarberichte iwb (2007) 88: Mechatronik—Vorsprung durch Simulation. Garching, München, 2007, pp 4-2–4-21

Smith KS, Winfough WR, Halley J (1998) The effect of tool length on stable metal removal rate in high speed milling. CIRP Ann 47(1):307–310

Smolik J (2008) Primary structural parts of machine tools made from unconventional materials. International Congress MATAR PRAHA 2008—Proceedings of Part 1: Drives & Control, Design, Models & Simulation, pp 65–70. ISBN 978-80-903421-9-4

Soucek P (2008) Feed drive influence on machining process stability. Int. Congress MATAR PRAHA—Proc. of Part 2: Testing, Technology, pp 75–80. ISBN 978-80-904077-0-1

Shi HM, Tobias SA (1984) Theory of finite amplitude machine tool instability. Int J Mach Tool Des Res 24(1):45–69

Shridar R, Hohn RE, Long GW (1968) A stability algorithm for the general milling process. J Eng Ind 90:330

Taylor FW (1907) On the art of cutting metals. Trans ASME 28:31–350

Tlusty J, Polacek H (1957) Beispiele der behandlung der selbsterregten schwingung der werkzeugmaschinen. Fo Ko Ma, Hanser Verlag, Munich

Tlusty J, Polacek H (1963) The stability of the machine tool against self-excited vibration in machining. ASME Prod Eng Res Conf, Pittsburgh

Tlusty J, Ismail F (1981) Basic non-linearity in machining chatter. CIRP Ann 30:229–304

Tlusty J, Ismail F (1983) Special aspects of chatter in milling. ASME J Vibration Stress Reliab Des 105:24–32

Tobias SA, Fishwick W (1958) The chatter of lathe tools under orthogonal cutting conditions. Trans ASME 80:1079

Tobias SA, Fishwick W (1958) Theory of regenerative machine tool chatter. The Engineer 205

Tobias SA (1965) Machine-tool vibration. Blackie and Sons Ltd, Glasgow

Vesely J, Sulitka M (2009) Machine tool virtual model. MM Sci J 2009:146–151

Zaeh M, Siedl D (2007) A new method for simulation of machining performance by integrating finite element and multi-body simulation for machine tools. CIRP Ann 56(1):383–386

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kolar, P., Sulitka, M. & Janota, M. Simulation of dynamic properties of a spindle and tool system coupled with a machine tool frame. Int J Adv Manuf Technol 54, 11–20 (2011). https://doi.org/10.1007/s00170-010-2917-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2917-7