Abstract

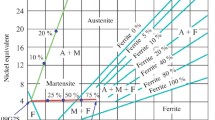

Butting bimetal pipes in duplex stainless steel are quite recent and present a set of interesting characteristics especially for oil and gas transportation, namely weight to corrosion resistance ratio. Gas tungsten arc (GTA) welding is used to join these pipes, but several problems are identified as lack of penetration and cracking resulting not only from the material itself, but also from the difficulty to weld in orbital position. In the present work, autogenous GTA pipe welding and pulse Rapid Arc gas metal arc welding of the pipes were studied. Current intensity, welding speed, electrode diameter, shielding gas and orbital positions were defined as variables. It was shown that under appropriate conditions, it is possible to obtain sound welds with proper geometry and defect free. The major limitation to penetration is the outwards flow pattern in the molten pool driven by the Marangoni effect, as a result of low sulphur content. Sulphur is an active surface element which reverses the surface tension coefficient to a positive effect. For penetrations of about 2 mm, a combination of current intensity of 170 A and a welding speed of 200 mm/min with an electrode angle of 30° under a shielding gas protection of He–25%Ar was defined for narrow groove welding of a J-bevelled pipe in flat position. No defects were detected in the inner layer in duplex stainless steel.

Similar content being viewed by others

References

(1998) Bi-metal line pipe provides improved corrosion protection. Oil Gas J 58(11). http://www.offshore-mag.com/index/article-display/24751/articles/offshore/volume-58/issue-11/news/general-interest/bi-metal-line-pipe-provides-improvedcorrosion-protection.html

BUTTING Co. (2008) Bi-metal pipe (BuBi®pipe). http://www.butting.de/bubi-pipe.html

Bingen M, Martensen E (2004) BuBi-pipe [butting-bimetal-pipe]—the intelligent cost-saving solution. Stainl Steel World 16:14–17

Banse J (1998) New material alternative: stainless and nickel bonded pipes. Stainl Steel World 10(3):48–49

DNV Pipeline Committee meeting (2008) Reel installation of clad steel pipe. www.edvermeulen.com/statoilclad180205.pdf. Accessed 08/01

American Welding Society (2004) Welding handbook, vol 2. Welding Processes, Miami

Gunn RN (1997) Duplex stainless steels: microstructure, properties and applications. Abington Publishing, Letchworth

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels. Wiley Interscience, Hoboken, NJ

Lincoln Electric Company (2005) RapidArc™—high speed GMAW welding, NX-2.80. http://content.lincolnelectric.com/pdfs/products/literature/nx280.pdf

Mills KC, Keene BJ, Brooks RF (1998) Marangoni effects in welding. Phil Trans Math Phys Eng Sci 356(1739):911–925

Lu SP, Fujii H, Nogi K (2004) Marangoni convection and weld shape variations in Ar–O2 and Ar–CO2 shielded GTA [TIG] welding. Mater Sci Eng, A 380(1–2):290–297

Lu SP, Fujii H, Sugiyama H (2003) Marangoni convection and welding penetration in ATIG welding. Trans JWRI 32(1):79–82

Heiple CR, Roper JR (1982) Mechanism for minor element effect on GTA fusion zone geometry. Weld J 61(4):97

Leinonen JI, Karjalainen LP (1990) Unexpected weld pool profiles in GTA [TIG] welding with oxidising shielding gas. In: David SA, Vitek JM (ed) Recent trends in welding science and technology proceedings, 2nd International Conference, Gatlinburg, TN, 14–18 May 1989, ASM International, Materials Park, OH, pp. 387–390

Lu SP, Fujii H, Nogi K (2004) Weld shape comparison with iron oxide flux and Ar–O2 shielding gas in gas tungsten arc welding. Sci Technol Weld Joining 9(3):272–276

Shanping L, Hidetoshi F, Kiyoshi N (2005) Effects of CO2 shielding gas additions and welding speed on GTA weld shape. J Mater Sci 40(9):2481–2485

Lu SP, Fujii H, Nogi K (2005) Influence of welding parameters and shielding gas composition on GTA [TIG] weld shape. ISIJ Int 45(1):66–70

Tušek J, Suban M (2000) Experimental research of the effect of hydrogen in argon as a shielding gas in arc welding of high-alloy stainless steel. Int J Hydrogen Energy 25:369–376

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torbati, A.M., Miranda, R.M., Quintino, L. et al. Welding bimetal pipes in duplex stainless steel. Int J Adv Manuf Technol 53, 1039–1047 (2011). https://doi.org/10.1007/s00170-010-2889-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2889-7