Abstract

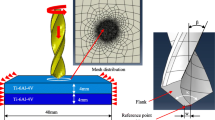

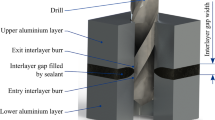

In the drilling of stacked materials, burrs produced on both the surface layer and the interlayer have some undesirable characters with regard to assembly quality, and deburring is a time consuming and costly operation. This paper presented an experimental study on the dry drilling of Ti-6Al-4V titanium alloy and 7075-T6 aluminum alloy stacked materials, which was performed by using uncoated cemented carbide drills. The burr size was evaluated at various spindle speeds, feed rates, stacking sequences, and clamp forces. After which, the burr morphology was observed and analyzed. Finally, a new multi-objective optimization algorithm, which was derived from the game theory, was used to select optimum process parameters to minimize burr size. The best process parameters recorded in this paper were at the spindle speed of 2,000 r/min, the feed rate of 0.075 mm/r, the pressure of 0.3 MPa, and the stacking sequence of the Ti-6Al-4V titanium alloy on top of the 7075-T6 aluminum alloy.

Similar content being viewed by others

References

Choi J, Min S (2003) Modeling of inter-layer gap formation in drilling of a multi-layered material. 2002-2003 LMA Reports, University of California at Berkeley, pp 36–41. http://www.escholarship.org/uc/item/2vb4t7gq?display=all#page-1

Aurich JC, Dornfeld D, Arrazola PJ, Franke V, Leitz L, Min S (2009) Burrs—analysis, control and removal. CIRP Ann 58:519–542

Miguel A, Joel G, Corinne RW, Athulan V, David D (2006) Strategies for burr minimization and cleanability in aerospace and automotive manufacturing. SAE Transactions J. of Aerospace 114:1073–1082

Lauderbaugh LK (2009) Analysis of the effects of process parameters on exit burrs in drilling using a combined simulation and experimental approach. J Mater Process Technol 209:1909–1919

Rivero A, Aramendi G, Herranz S, López de Lacalle LN (2006) An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int J Adv Manuf Technol 28:1–11

Cantero JL, Tardío MM, Canteli JA, Marcos M, Miguélez MH (2005) Dry drilling of alloy Ti–6Al–4V. Int J Mach Tools Manuf 45:1246–1255

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6Al-4V. CIRP Ann 48:73–76

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2007) Methodology of Taguchi optimization for multi-objective drilling problem to minimize burr size. Int J Adv Manuf Technol 34:1–8

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2008) Genetic algorithm-based burr size minimization in drilling of AISI 316L stainless steel. J Mater Process Technol 197:225–236

Gaitonde VN, Karnik SR, Siddeswarappa B, Achyutha BT (2008) Integrating Box-Behnken design with genetic algorithm to determine the optimal parametric combination for minimizing burr size in drilling of AISI 316L stainless steel. Int J Adv Manuf Technol 37:230–240

Ramulu M, Branson T, Kim D (2001) A study on the drilling of composite and titanium stacks. Compos Struct 54:67–77

Newton TR, Morehouse J, Melkote SN, Turner S (2008) An experimental study of interfacial burr formation in drilling of stacked aluminium sheets. Transactions of NAMRI/SME 36:437–444

Melkote SN, Newton TR, Hellstern C, Morehouse JB, Turner S (2009) Interfacial burr formation in drilling of stacked aerospace materials. In: Proceedings of the CIRP International Conference on Burrs: analysis, control and removal, University of Kaiserslautern, Germany, pp 89–98

Heisel U, Luik M, Eisseler R, Schaal M (2005) Prediction of parameters for the burr dimensions in short-hole drilling. CIRP Ann 54:79–82

Liang J, Bi SS (2010) Design and experimental study of an end effector for robotic drilling. Int J Adv Manuf Technol. doi:10.1007/s00170-009-2494-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bi, S., Liang, J. Experimental studies and optimization of process parameters for burrs in dry drilling of stacked metal materials. Int J Adv Manuf Technol 53, 867–876 (2011). https://doi.org/10.1007/s00170-010-2877-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2877-y