Abstract

The wear rate model of 7.3 vol.% Al2O3 particle-reinforced aluminium alloy composites with 16 and 66 µm particle sizes fabricated by molten metal mixing method was developed in terms of applied load, particle size of reinforcement, abrasive grain size and sliding distance based on the Taguchi method. The two-body abrasive wear behaviour of the specimens was investigated using a pin-on-disc abrasion test apparatus where the sample slid against different SiC abrasives under the loads of 2 and 5 N at the room conditions. The orthogonal array, signal-to-noise ratio and analysis of variance were employed to find out the optimal testing parameters. The test results showed that particle size of reinforcement was found to be the most effective factor among the other control parameters on abrasive wear, followed by abrasive grain size. Moreover, the optimal combination of the testing parameters was determined and predicted. The predicted wear rate results were compared with experimental results and found to be quite reliable.

Similar content being viewed by others

References

Warren H, Hunt JR (2000) Particulate reinforced MMCs. In: Kelly A, Zweben C (eds) Comprehensive composite materials, vol. 3. Metal Matrix Composites. In: T.W. Clyne (Vol. Editor), Pergamon, Oxford, pp 701–715

Raghumatham N, Ioannidis EK, Sheppard T (1991) Fabrication, properties and structure of a high temperature light alloy composite. J Mater Sci 26:985–992

Shibata K, Ushio H (1994) Tribological application of MMCs for reducing engine weight. Tribol Int 27:39–41

Chellman DJ, Langenbeck SL (1993) Aerospace applications of advanced aluminum alloys. Key Eng Mater 77–78:49–60

Prasad SV, Rohatgi PK (1987) Tribological properties of Al alloy particle composite. J Metall 39:22

Rana F, Stefanescu DM (1989) Friction properties of Al-1.5%Mg-SiC particulate metal matrix composite. Metall Trans 20:1564–1566

Surappa MK, Prasad SV, Rohatgi PK (1982) Wear and abrasion of cast Al-alumina particle composites. Wear 77:295–312

Banerjee A, Prasad SV, Surappa MK, Rohatgi PK (1982) Abrasive wear of cast aluminium alloy-zircon particle composites. Wear 82:141–151

Bhansali KJ, Mehrabian R (1982) Abrasive wear of aluminium matrix composites. J Met 32:30–34

Prasad BK, Prasad SV, Das AA (1992) Abrasion-induced microstructural changes and material removal mechanisms in squeeze-cast aluminium alloy-silicon carbide composites. J Mater Sci 27:4489–4494

Jasim KM, Dwarakadasa ES (1987) Wear in Al-Si alloys under dry sliding conditions. Wear 119:119–130

Kanth VK, Pramila Bai BN, Biswas SK (1990) Wear mechanisms in a hyper-eutectic aluminium silicon alloy sliding against steel. Scr Metall Mater 24:267–271

Kök M (2006) Abrasive wear of Al2O3 particle reinforced 2024 aluminium alloy composites fabricated by vortex method. Compos A 37:457–464

Dellis MA, Keastenrmans JP, Delannay F (1991) The wear properties of aluminium alloy composite. Mater Sci Eng A 135:253–257

Ma ZY, Liang YN, Zhang YZ, Lu YX, Bi J (1996) Sliding wear behaviour of SiC particle reinforced 2024 aluminium alloy composites. Mater Sci Technol 12:751–756

Deuis RL, Subrammanian C, Yellup JM (1996) Abrasive wear of Al alloy composites; a review. Wear 201:132–144

Alpas AT, Zhang J (1992) Effect of SiC particulate reinforcement on the dry sliding wear of aluminium-silicon alloys. Wear 155:83–104

Moustafa SF (1995) Wear and wear mechanisms of Al-22% Si/Al2O3f. Wear 185:189–195

Straffelini G, Bonollo F, Tizaiani A, Molinari A (1997) Influence of matrix hardness on the dry sliding behaviour of 20 vol.% Al2O3-particulate-reinforced 6061 Al metal matrix composite. Wear 211:192–197

Hutchings IM (1994) Tribological properties of metal matrix composites. Mater Sci Technol 10:513–517

Prasad BK, Das S, Jha AK, Modi OP, Dasgupta R, Yegneswaran AH (1997) Factors controlling the abrasive wear response of a zinc-based alloys silicon carbide particle composite. Compos A 28A:301–308

Mondal DP, Das S, Jha AK, Yegneswaran AH (1998) Abrasive wear of Al alloy-Al2O3 particle reinforced composite; a study on the combined effect of load and size of abrasive. Wear 223:131–138

Modi OP, Yadav RP, Mondal DP, Dasgupta R, Das S, Yegneswaran AH (2001) Abrasive wear of zinc-Al alloy-10% Al2O3 composite through factorial design. J Mater Sci 36:1601–1607

Sahin Y (2003) Wear behaviour of aluminium alloy and its composites reinforced by SiC particles using statistical analysis. Mater Des 24:95–103

Sahin Y (2005) The prediction of wear resistance model for metal matrix composites. Wear 258:1717–1722

Sahin Y (2007) Tribological behaviour of metal matrix and its composite. Mater Des 28:1348–1352

Sahin Y, Özdin K (2008) A model for the abrasive wear behaviour of aluminium based composites. Mater Des 29:728–733

Basavarajappa S, Chandramohan G, Paulo Davim J (2007) Application of Taguchi techniques to study dry sliding wear behaviour of metal matrix composites. Mater Des 28:1393–1398

Kumar S, Balasubramanian V (2008) Developing a mathematical model to evaluate wear rate of AA7075/SiCp powder metallurgy composites. Wear 264:1026–1034

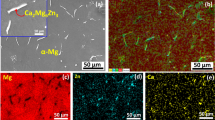

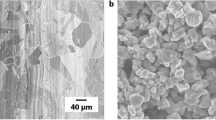

Kok M (2005) Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J Mater Process Technol 161:381–387

Sheu SY, Lin SJ (1996) Particle size effect on the abrasion wear of 20 vol.% SiCp/7075 Al composites. Scr Mater 35(11):1271–1276

Spuzic S, Zec M, Abhary K, Ghomashchi R, Reid I (1997) Fractional design of experiments applied to a wear simulation. Wear 212:131–139

Wang AG, Hutchings IM (1989) Wear of alumina fiber aluminium metal matrix composites by two-body abrasion. Mater Sci Technol 5:71–76

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kök, M. Computational investigation of testing parameter effects on abrasive wear behaviour of AL2O3 particle-reinforced MMCS using statistical analysis. Int J Adv Manuf Technol 52, 207–215 (2011). https://doi.org/10.1007/s00170-010-2734-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2734-z