Abstract

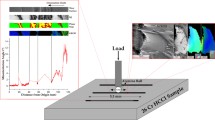

Erosion characteristics of high chromium (Cr, 16–19%) alloy cast iron with 5% and 10% manganese (Mn) prepared in metal and sand moulds through induction melting are investigated using jet erosion test setup in both as-cast and heat-treated conditions. The samples were characterised for hardness and microstructural properties. A new and novel non-destructive evaluation technique namely positron lifetime spectroscopy has also been used for the first time to characterise the microstructure of the material in terms of defects and their concentration. We found that the hardness decreases irrespective of the sample condition when the mould type is changed from metal to sand, On the other hand, the erosion volume loss shows an increasing trend. Since the macroscopic properties have a bearing on the microstructure, good credence is obtained from the microstructural features as seen from light and scanning electron micrographs. Faster cooling in the metal mould yielded fine carbide precipitation on the surface. The defect size and their concentration derived from positron method are higher for sand mould compared to metal mould. Lower erosion loss corresponds to smaller size defects in metal mould are the results of quicker heat transfer in the metal mould compared to the sand mould. Heat treatment effects are clearly seen as the reduced concentration of defects and spherodisation of carbides points to this. The erosion loss with respect to the defects size and concentration correlate very well.

Similar content being viewed by others

References

Krishnamoorrthy PR, Seetharamu S, Sampathkumaran P (1999) Erosion wear in thermal power plants, 55th R and D Session of CBI & P, India July 1

Pearce JTH (1984) Structure and wear performance of abrasion resistant chromium white cast irons. AFS transactions 126:599

Basak A, Pening J, Dellewyns J (1981) Effect of manganese on wear resistant and impact strength of 12% chromium white cast iron, AFS International Cast Metal Journal 12–17

Hartley JH, Howell RH, Asoka-Kumar P, Sterne PA, Akers D, Denison A (1999) Appl Surf Sci 149:204

Bernal MJ, de la Cruz RM, Leguey T, Pareja R, Riveiro JM (1995) Mater Sci Forum 299:175–178

François Rossi, Bernard André, A van Veen, PE Mijnarends, H Schut, F Labohm, Hugh Dunlop, Marie Paule Delplancke, Kevin Hubbard (1994) Journal of Materials Research 9:2440–2449, MRS publication

Hautojarvi P (1979) Positrons in solids. Springer, Berlin

Kawaguchi Y, Shirai Y (2002) Fatigue evaluation of type 316 stainless steel using positron annihilation line shape analysis and β+-γ coincidence positron lifetime measurement. J Nucl Sci Technol 39–10:1033–1040

Wu YC, Zhang R, Chen H, Li Y, Zhang J, D-M Zhu, Jean YC (2003) Corrosion of iron and stainless steels studied using slow positron beam technique. Radiat Phys Chem 68:599–603

Abdel-Hady EE (2003) Application of positron lifetime spectroscopy to the study of microstructural defects in steel. Egypt J Sol 26–2:165–174

Sampathkumaran P, Seetharamu S, Kishore (2005) Erosion and abrasion characteristics of high manganese chromium irons. Wear 259:70–77

Ravikumar HB, Ranganathaiah C, Kumaraswamy GN, Siddaramaiah (2005) Influence of free volume on the mechanical properties of epoxy/poly (methylmethacrylate) blends. J Mat Sci 40:6523

Kirkegaard P, Pederson NJ, Eldrup M (1989) PATFIT-88: Riso National Laboratory Report PM-2724. Riso National Laboratory, Riso

Brandt W, Dupasquier A (1983) Positron solid state physics. North-Holland, Amsterdam

Raask E (1980) Erosion wear in coal utilization. Hamisphere, New York

Shikata S, Fujii S, Wei L, Tanigawa S (1992) Effect of annealing method on vacancy type defects in Si implanted GaAs studies by a slow positron beam. J Appl Phys 31:732–736

Campillo Robles JM, Ogando E, Plazaola F (2007) Positron lifetime calculation for the elements of the periodic table. J Phys Condens Matter 19:176222, 22 p

Kulkarni SN, Radhakrishna K (2005) Evaluation of metal-mould interfacial heat transfer during the solidification of aluminium—4.5% copper alloy castings cast in CO2 sand moulds. Mater Sci—Poland 23:3

Laird G II (1993) Some comments on white cast iron microstructures and wear properties. AFS transactions 128:497–504

Seetharamu S, Sampathkumaran P, Kumar RK (1995) Erosion resistant of permanent moulded high chromium iron. Wear 267:159–167

Norman TE, Solomon A, Doane DV (1977) Martensitic white irons for abrasion resistant castings. AFS 77:242–256

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sampathkumaran, P., Ranganathaiah, C., Seetharamu, S. et al. Chromium–manganese iron alloy system design cast in metal and sand moulds for erosion resistance: a positron lifetime study. Int J Adv Manuf Technol 52, 45–52 (2011). https://doi.org/10.1007/s00170-010-2715-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2715-2