Abstract

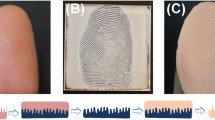

Micro-hairs are profound elements widely used in nature. A great variety of animals use them as sensors to gather information about their surroundings. To artificially fabricate these kinds of sensors, we present a method to produce micro-hairs made of polydimethylsiloxane (PDMS). We investigated the laser micro-drilling of wax and polycarbonate (PC) substrates with a 193-nm ArF laser to produce molds suitable for casting micro-hairs. Especially PC molds lead to high-quality micro-hairs. Thus, laser ablation of PC was intensively studied. In order to obtain micro-hair arrays, experiments where performed to optimize the casting techniques of PDMS in PC molds. The possibilities and limitations of the investigated method of micro-hair production are presented.

Similar content being viewed by others

References

Liang YA, Autumn K, Hsieh ST, Zesch W, Chan WP, Fearing RS, Full RJ, and Kenny TW (2000) Adhesion force measurements on single gecko setae. Technical Digest. Solid-State Sensor and Actuator Workshop, pp 33–38

Dangles O, Magal C, Pierre D, Olivier A, Casas J (2005) Variation in morphology and performance of predator-sensing system in wild cricket populations. J Exp Biol 208:461–468

Landolfa MA, Jacobs GA (1995) Direction sensitivity of the filiform hair population of the cricket cercal system. J Comp Physiol A 177:759–766

Dechant HE, Rammerstorfer FG, Barth FG (2001) Arthropod touch reception: stimulus transformation and finite element model of spider tactile hairs. J Comp Physiol A 187:313–322

van Baar J, Dijkstra M, Wiegerink R, Lammerink T, de Boer R, and Krijnen G (2005) Arrays of cricket-inspired sensory hairs with capacitive motion detection. IEEE Micro Elctro Mechanical Systems Workshop, 646–649

Engel JM, Chen J, Bullen D, and Liu C (2005) Polyurethane rubber as a MEMS material: characterization and demonstration of an all-polymer two-axis artificial hair cell flow sensor. 18th IEEE International Conference on Micro Electro Mechanical Systems, pp 279–282

Sitti M, Fearing RS (2003) Synthetic gecko foot-hair micro/nano-structures as dry adhesives. J Adhes Sci Technol 17:1055–1073

Schmitz GJ, Brücker C, Jacobs P (2005) Manufacture of high-aspect-ratio micro-hair sensor arrays. J Micromechanics Microengineering 15:1904–1910

Xia YN, Whitesides GM (1998) Soft lithography. Ann Rev Mater 29:153–184

Bashir A, Katila P, Ogier N, Saadany B, Khalil DA (2004) A MEMS-based VOA with very low PDL. IEEE Photonics Technol Lett 16:1047–1049

Rebello KJ (2004) Applications of MEMS in surgery. Proc IEEE 92:43–55

Roy S, Ferrara LA, Fleischmann AJ, Benzel EC (2001) Microelectromechanical systems and neurosurgery: a new era in a new millennium. Neurosurgery 49:779–797

Mata A, Fleischman AJ, Roy S (2005) Characterization of polydimetylsiloxane (PDMS) properties for biomedical micro/nanosystems. Biomedical Microdevices 7(4):281–293

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schaefer, M., Jacobs, P., Bauer, D. et al. Investigation and development of a molding process for the production of micro-hairs. Int J Adv Manuf Technol 51, 935–944 (2010). https://doi.org/10.1007/s00170-010-2670-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2670-y