Abstract

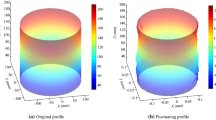

Form deviations of cylindrical features present in the manufactured parts are measured using coordinate measuring machine (CMM) and expressed as circularity or cylindricity errors evaluated using appropriate reference features. In the present work, computational geometric techniques are used to establish a circle as reference feature, and a heuristic algorithm is proposed to get a unique convex inner hull. Using the concept of equi-distant lines and diagrams, minimum circumscribed (MC), maximum inscribed (MI), and minimum zone (MZ) circles are established. For the first time, algorithms purely based on computational geometric concepts have been developed in the present work to arrive at MC, MI, and MZ circular cylinders. As the algorithms and the implementation details are explained with simple data sets, the practitioners can easily understand these methods and implement them in CMMs for the evaluation of circularity and cylindricity errors. The algorithms are also tested on larger datasets, and in all cases, accurate results are obtained in less than a second.

Similar content being viewed by others

References

Carr K, Ferreira P (1995) Verification of form tolerances part II: cylindricity and straightness of a median line. Precis Eng 17:144–156

Chetwynd DG (1979) Roundness measurement using limacons. Precis Eng 1(3):137–141

Chetwynd DG, Phillipson PH (1980) An investigation of reference criteria used in roundness measurement. Phys E: Sci Instrum 13:530–538

Huang J (1999) An exact solution for the roundness evaluation problems. Precis Eng 23(4):2–8

Huang J (2001) A new strategy for circularity problems. Precis Eng 25(4):301–308

ISO11011983 (2000) Technical drawings: tolerancing of form, orientation, location, and runout. Generalities, definitions, symbols, indications on drawing. BSI Customer Services, London

Murthy TSR, Abdin SZ (1980) Minimum zone evaluation of surfaces. Int J Mach Tools Des Res 2:123–136

O’Rourke J (1997) Computational geometry in C. Cambridge University Press, Cambridge

Preparata FP, Shamos MI (1985) Computational geometry: an introduction. Springer, New York

Radhakrishnan S, Ventura JA, Ramaswamy SE (1998) The minimax cylinder estimation problem. J Manuf Syst 17(2):97–106

Roy U, Zhang X (1994) Development and application of Voronoi diagrams in the assessment of roundness error in an industrial environment. Comp Indl Eng 26(1):11–26

Roy U, Xu Y (1995) Form and orientation tolerance analysis for cylindrical surfaces in computer-aided inspection. Comput Ind 26:127–134

Samuel GL, Shunmugam MS (2000) Evaluation of circularity from coordinate and form data using computational geometric techniques. Precis Eng 24:251–263

Shunmugam MS (1986) On assessment of geometric errors. Int J Prod Res 24(2):413–425

Shunmugam MS, Venkaiah N (2010) Influence of eccentricity and axis tilt on circularity and cylindricity assessments. Int J Precision Technol 1:234–250

Venkaiah N, Shunmugam MS (2007) Evaluation of form data using computational geometric techniques, part I: circularity error. Int J Mach Tools Manuf 47(7–8):1229–1236

Venkaiah N, Shunmugam MS (2007) Evaluation of form data using computational geometric techniques, part II: cylindricity error. Int J Mach Tools Manuf 47(7–8):1237–1245

Xiuming L, Zhaoyao S (2009) The relationship between the minimum zone circle and the maximum inscribed circle and the minimum circumscribed circle. Precis Eng 33(3):284–290

Whitehouse DJ (1973) A best fit reference line for use in partial arcs. J Phys E: Sci Instruments 6:921–924

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shunmugam, M.S., Venkaiah, N. Establishing circle and circular-cylinder references using computational geometric techniques. Int J Adv Manuf Technol 51, 261–275 (2010). https://doi.org/10.1007/s00170-010-2577-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2577-7