Abstract

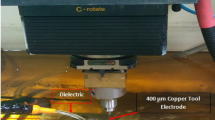

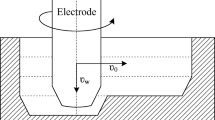

Electrical discharge machining (EDM) is an important and widely used process for the fabrication of complex three-dimensional structure of micro-tools, micro-components, and parts with micro-feature. It allows high precision, low setup cost, large freedom of design, and good surface quality. However, in order to produce different varieties of high-accuracy structures on machine, microelectrode fabrication is necessary so as to reduce the clamping error which is one of the biggest challenges in the field of micro-EDM. In this study, it has been shown that localized electrochemical deposition (LECD) is one of the simplest, inexpensive, and damage-free ways to fabricate complex-shaped electrodes for micro-EDM compared to other conventional electrode fabrication processes. In this study, electrode was fabricated with the help of a non-conductive mask which was placed between the anode and the cathode where the cathode was placed above the anode and mask and the system was immersed in a plating solution of acidified copper sulfate. The micro-EDM was carried out by the deposited electrode without changing or removing its orientation. The performance of LECD electrode was evaluated in this study by micro-holes fabrication on high melting point material such as stainless steel in terms of the material removal rate, tool relative wear ratio, and dimensional accuracy. Finally, the performance of the LECD electrode was also evaluated by a comparative study with a circular EDM electrode for fabrication of complex three-dimensional structure.

Similar content being viewed by others

References

Masuzawa T (2000) State of the art of micromachining. Annals of the CIRP 49(2):473–488

Kim BH, Park BJ, Chu CN (2006) Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J Micromechanics Microengineering 16:843–850

Lim HS, Wong YS, Rahman M, Lee MKE (2003) A study on the machining of high-aspect ratio micro-structures using micro-EDM. J Mater Process Technol 140:318–325

Weng FT, Shyu RF, Hsu CS (2003) Fabrication of micro-electrodes by multi-EDM grinding process. J Mater Process Technol 140:332–334

Pratt SD, Muthuswamy S and Pennisi RW (1998) Electrical discharge machining electrode and rapid method for fabricating same. US Patent 5,818,005

Tang Y, Hong J, Zhou H, Lu B (2005) A new technique for the fabrication of graphite EDM electrodes. J Mater Process Technol 166:199–204

Zhao J, Li Y, Zhang J, Yu C, Zhang Y (2003) Analysis of the wear characteristics of an EDM electrode made by selective laser sintering. J Mater Process Technol 138:475–478

Weng FT (2004) Fabrication of microelectrodes for EDM machining by a combined etching process. J Micromechanics Microengineering 14:N1–N4

Lim HJ, Lim YM, Kim SH (2003) Fabrication of arbitrarily shaped microelectrodes by electrochemical etching. Japan Journal Applied Physics 42:1479–1485

Rahman M, Kumar AS, Prakash JRS (2001) Micro-milling of pure copper. J Mater Process Technol 116:39–43

Lu Z, Yoneyama T (1999) Micro-cutting in the micro-lathe turning system. Int J Mach Tools Manuf 39:1171–1183

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46:313–332

Takahata K, Shibaike N, Guckel H (2000) High-aspect-ratio WC-Co microstructure produced by the combination of LIGA and micro-EDM. Microsyst Technol 6:1432–1858

Hunter IW, Lafontaine SRand Madden JD (1997) Three-dimensional microfabrication by localized electrochemical deposition and etching. US Patent Specification 5,641,391

Madden JD, Hunter IW (1997) Three-dimensional micro-fabrication by localized electrochemical deposition. Journal of Microelectromechanical Systems 5:24–32

Habib MA, Gan SWand Rahman M (2009) Fabrication of complex shape electrodes by localized electrochemical deposition. J Mater Process Technol 209(9):4453–4458

Habib MA, Gan SW, Lim HS, Rahman M (2008) Fabrication of EDM electrodes by localized electrochemical deposition. International Journal of Precision Engineering and Manufacturing 9(2):75–80

Lee SH, XP L (2001) Study of the effect of machining parameters on the machining characteristics in EDM of WC. J Mater Process Technol 115:344–355

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Habib, M.A., Rahman, M. Performance analysis of EDM electrode fabricated by localized electrochemical deposition for micro-machining of stainless steel. Int J Adv Manuf Technol 49, 975–986 (2010). https://doi.org/10.1007/s00170-009-2479-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2479-8