Abstract

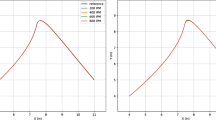

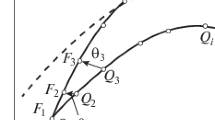

For CNC machines governed by typical feedback controllers, the problem of compensating for inertia and damping of the machine axes is solved by a priori modifications to the commanded path geometry. Standard second-order models of axis dynamics are expressed in terms of the path parameter ξ rather than the time t as independent variable, incurring ordinary differential equations with polynomial coefficients. For a commanded path specified as a Pythagorean-hodograph curve R(ξ) and a P controller, a modified path \(\hat{\bf R}(\xi)\) can be determined as a rational Bézier curve, that precisely compensates for the axis inertia and damping, and thus (theoretically) achieves zero contour error. For PI, PID, or P–PI controllers, exact closed-form solutions for \(\hat{\bf R}(\xi)\) are no longer possible, but polynomial approximations may be computed in the numerically stable Bernstein basis on ξ ∈ [ 0,1 ]. The inverse-dynamics path modification procedure is applicable to both constant feedrates and variable feedrates defined by polynomial functions V(ξ) of the curve parameter. The method is described in the general context of PID controllers, and its implementation is then demonstrated for both P and PI controllers, governing motion along paths with extreme variations of curvature and/or parametric speed.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Altintas Y (2000) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge University Press, Cambridge

Coddington EA (1961) An introduction to ordinary differential equations. Dover, New York (reprint)

Davis PJ (1975) Interpolation and approximation. Dover, New York (reprint)

de Souza AF, Coelho RT (2007) Experimental investigation of feed rate limitations on high speed milling aimed at industrial applications. Int J Adv Manuf Technol 32:1104–1114

Erkorkmaz K, Yeung C-H, Altintas Y (2006) Virtual CNC system. Part II. High speed contouring application. Int J Mach Tools Manuf 46:1124–1138

Farouki RT (1994) The conformal map z→z 2 of the hodograph plane. Comput Aided Geom Des 11:363–390

Farouki RT (2008) Pythagorean-hodograph curves: algebra and geometry inseparable. Springer, Berlin

Farouki RT, Goodman TNT (1996) On the optimal stability of the Bernstein basis. Math Comput 65:1553–1566

Farouki RT, Neff CA (1995) Hermite interpolation by Pythagorean-hodograph quintics. Math Comput 64:1589–1609

Farouki RT, Rajan VT (1987) On the numerical condition of polynomials in Bernstein form. Comput Aided Geom Des 4:191–216

Farouki RT, Rajan VT (1988) Algorithms for polynomials in Bernstein form. Comput Aided Geom Des 5:1–26

Farouki RT, Sakkalis T (1991) Real rational curves are not “unit speed.” Comput Aided Geom Des 8:151–157

Farouki RT, Sakkalis T (2007) Rational space curves are not “unit speed.” Comput Aided Geom Des 24:238–240

Farouki RT, Shah S (1996) Real-time CNC interpolators for Pythagorean-hodograph curves. Comput Aided Geom Des 13:583–600

Farouki RT, Tsai Y-F (2001) Exact Taylor series coefficients for variable-feedrate CNC curve interpolators. Comput Aided Des 33:155–165

Hausdorff F (1957) Set theory (translated by J. R. Aumann et al.). Chelsea, New York

Imani BM, Jahanpour J (2008) High-speed contouring enhanced with PH curves. Int J Adv Manuf Technol 37:747–759

Jahanpour J, Imani BM (2008) Real-time PH curve CNC interpolators for high speed cornering. Int J Adv Manuf Technol 39:302–316

Komanduri R, Subramanian K, von Turkovich BF (eds) (1984) High speed machining. PED, vol 12. ASME, New York

Shpitalni M, Koren Y, Lo CC (1994) Realtime curve interpolators. Comput Aided Des 26:832–838

Smith S, Tlusty J (1997) Current trends in high-speed machining. ASME J Manuf Sci Eng 119:664–666

Tlusty J (1993) High-speed machining. CIRP Ann 42:733–738

Tsai Y-F, Farouki RT (2001) Algorithm 812: BPOLY: an object-oriented library of numerical algorithms for polynomials in Bernstein form. ACM Trans Math Softw 27:267–296

Yang DCH, Kong T (1994) Parametric interpolator versus linear interpolator for precision CNC machining. Comput Aided Des 26:225–234

Yeh S-S, Hsu P-L (1999) The speed-controlled interpolator for machining parametric curves. Comput Aided Des 31:349–357

Yeung, C-H, Altintas Y, Erkorkmaz K (2006) Virtual CNC system. Part I. System architecture. Int J Mach Tools Manuf 46:1107–1123

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Ernesto, C.A., Farouki, R.T. Solution of inverse dynamics problems for contour error minimization in CNC machines. Int J Adv Manuf Technol 49, 589–604 (2010). https://doi.org/10.1007/s00170-009-2407-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2407-y