Abstract

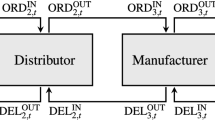

Multisite factories geographically distributed often have to implement an opportune tool to integrate their resources and demand forecasts in order to gather a specific production objective. The proposed research develops a distributed approach, for a network of independent enterprises, able to facilitate the capacity process by using a multiagent architecture and a cooperative protocol. The last one is based on game theory and, in particular, on Nash bargaining solution. Moreover, a discrete simulation environment has been developed to compare the proposed approach with the one in which no cooperation among enterprises exist. Several simulation scenarios were conducted to analyze the performances’ trends in various environment conditions. The goal has been the evaluation of the unallocated capacity, the unsatisfied demand, the profits generated by the network, the distribution of the transactions among the plants, and the number of activated links among plants. The simulation results show that the proposed approach leads to a better performance indexes and more relevant benefits when the dynamicity of the environment growths.

Similar content being viewed by others

References

Argoneto P, Bruccoleri M, Lo Nigro G, Perrone G, Noto La Diega S, Renna P (2006) High level planning of reconfigurable enterprises: a game theoretic approach. Ann CIRP 55(1):509–512

Baum J, Calabrese T, Silverman B (2000) Don’t go it alone: alliance network composition and startups’ performance in Canadian biotechnology. Strateg Manage J 21(3):267–294

Chen JC, Wang KJ, Wang SM, Jang SJ (2008) Price negotiation for capacity sharing in two-factory environment using genetic algorithm. Int J Prod Res 46(7):1847–1868

Christie RME, Wu SD (2002) Semiconductor capacity planning: stochastic modelling and computational studies. IIE Trans 34(2):131–144

Dollinger M (1985) Environmental contacts and financial performance of the small firm. J Small Bus Manage 23(1):24–30

Dowling M, Lechner C, Bau F (1998) Kooperative Wettbewerbsbeziehungen-eine empirische Untersuchung. In: Franke N, von Braun CF (eds) Innovationsforschung und Technologiemanagement. Springer, Berlin

Ip WH, Li Y, Man KF, Tang KS (2000) Multi-product planning and scheduling using genetic algorithm approach. Comput Ind Eng 38:283–296

Jiang AX (2000) Capacity trading among semiconductor manufacturing factories. Master’s thesis, Graduate Institute of Industrial Engineering, National Taiwan University

Lechner C, Dowling M (2003) Firm networks: external relationships as sources for the growth and competitiveness of entrepreneurial firms. Entrep Reg Dev 15:1–26

Renna P, Argoneto P (2008) Capacity allocation in multi-site factory environment: a multi agent systems approach. Proceedings of the Innovative and Cognitive Production Technology and Systems, 23–25 July, Naples, Italy

Tonshoff HK, Seilonen L, Teunis G, Leitao P (2000) A mediator-based approach for decentralised production planning, scheduling and monitoring. Report of the Espirit Program EP 24986

Wang KJ, Lin SH (2002) Capacity expansion and allocation for semiconductor testing facility with constrained budget. Prod Plan Control 13:429–437

Wu MC, Chang WJ (2007) A short-term capacity trading method for semiconductor fabs with partnership. Expert Syst Appl 33(2):476–483

Wu M-C, Hsiung Y, Hsu H-M (2005) A tool planning approach considering cycle time constraints and demand uncertainty. Int J Adv Manuf Technol 26(5):565–571

Wu SD, Erkoc M, Karabuk S (2005) Managing capacity in the high-tech industry: a review of literature. Eng Econ 50:125–158

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Renna, P., Argoneto, P. A game theoretic coordination for trading capacity in multisite factory environment. Int J Adv Manuf Technol 47, 1241–1252 (2010). https://doi.org/10.1007/s00170-009-2254-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2254-x