Abstract

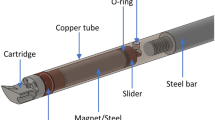

An innovative chatter suppression method based on a magnetorheological (MR) fluid-controlled boring bar for chatter suppression is developed. The MR fluid, which can change stiffness consecutively by varying the strength of the applied magnetic field, was applied to adjust the stiffness of the boring bar and suppress chatter. The cutting dynamic stability under different natural frequencies of the structure was analyzed by an energy method, which shows that cutting dynamic stability depends on both the natural frequency of the structure and the spindle speed. The chatter suppression mechanism with varying natural frequency is analyzed for further parameter optimization. Furthermore, both theoretical analyses and numerical simulations indicate that a square wave exciting current with a large amplitude and a moderate frequency has a better effect on regenerative chatter suppression. Experiments utilizing a MR fluid-controlled boring bar under an exciting current with different waveforms and frequencies were conducted. The experimental results show that the chatter can be significantly suppressed using MR fluid-controlled boring bar under a square wave exciting current with a frequency of 4–6 Hz and an amplitude of 0–2 A.

Similar content being viewed by others

References

Lee DG, Suh NP (1984) Manufacturing and testing of chatter free boring bars. CIRP Annals—Manufacturing Technology 37(1):365–368. doi:10.1016/S0007-8506(07)61655-2

Anderson CS, Semercigil SE, Turan ÖF (2007) A passive adaptor to enhance chatter stability for end mills. Int J Mach Tools Manuf 47(11):1777–1785. doi:10.1016/j.ijmachtools.2006.06.020

Budak E, Tekeli A (2005) Maximizing chatter free material removal rate in milling through optimal selection of axial and radial depth of cut pairs. CIRP Annals—Manufacturing Technology 54(1):353–356. doi:10.1016/S0007-8506(07)60121-8

Ema S, Marui E (2008) Suppression of chatter vibration of boring tools using impact dampers. Int J Mach Tools Manuf 40(8):1141–1156. doi:10.1016/S0890-6955(99)00119-4

Liu KJ, Rouch KE (1991) Optimal passive vibration control of cutting process stability in milling. J Mater Process Technol 28(1–2):285–294. doi:10.1016/0924-0136(91)90227-6

Sims ND (2007) Vibration absorbers for chatter suppression: a new analytical tuning methodology. J Sound Vib 301(3-5):592–607. doi:10.1016/ j.jsv.2006.10.020

Albizuri J, Fernandes MH, Garitaonandia I, Sabalza X, Uribe-Etxeberria R, Hernández JM (2007) An active system of reduction of vibrations in a centerless grinding machine using piezoelectric actuators. Int J Mach Tools Manuf 47(10):1607–1614. doi:10.1016/j.ijmachtools.2006.11.004

Tanaka H, Obata F, Matsubara T, Mizumoto H (1994) Active chatter suppression of slender boring bar using piezoelectric actuators. JSME Int J, Ser C—Dyn Control Robotics Des Manuf 37(3):601–606 http://ci.nii.ac.jp/naid/110004069087/

Knospe CR (2007) Active magnetic bearings for machining applications. Control Eng Pract 15(3):307–313. doi:10.1016/j.conengprac.2005.12.002

Chen M, Knospe CR (2007) Control approaches to the suppression of machining chatter using active magnetic bearings. IEEE Trans Control Syst Technol 15(2):220–232. doi:10.1109/TCST.2006.886419

Dohner JL, Lauffer JP, Hinnerichs TD, Shankar N, Regelbrugge M, Kwan CM, Xu R, Winterbauer B, Bridger K (2004) Mitigation of chatter instabilities in milling by active structural control. J Sound Vib 269(1–2):197–211. doi:10.1016/S0022-460X(03)00069-5

Brecher C, Schulz A, Week M (2005) Electrohydraulic active damping system. CIRP Annals—Manufacturing Technology 54(1):389–392. doi:10.1016/S0007-8506(07)60129-2

Ganguli A, Deraemaeker A, Preumont A (2007) Regenerative chatter reduction by active damping control. J Sound Vib 300(3–5):847–862. doi:10.1016/ j.jsv.2006.09.005

Ganguli A, Deraemaeker A, Horodinca M, Preumont A (2005) Active damping of chatter in machine tools—demonstration with a ‘hardware-in-the-loop’ simulator. Proc Inst Mech Eng, Part I: J Syst Control Eng 219(5):359–369. doi:10.1243/095965105X33455

Tarng YS, Hseih YW, Li TC (1996) Automatic selection of spindle speed for suppression of regenerative chatter in turning. Int J Adv Manuf Technol 11(1):12–17. doi:10.1007/BF01177179

Yilmaz A, Al-Regib E, Ni J (2002) Machine tool chatter suppression by multi-level random spindle speed variation. Trans ASME, J Manuf Sci Eng 124(2):208–216. doi:10.1115/1.1378794

Al-Regib E, Ni J, Lee SH (2003) Programming spindle speed variation for machine tool chatter suppression. Int J Mach Tools Manuf 43(12):1229–1240. doi:10.1016/S0890-6955(03)00126-3

Yang FL, Zhang B, Yu JY (2003) Chatter suppression with multiple time-varying parameters in turning. J Mater Process Technol 141(3):431–438. doi:10.1016/S0924-0136(03)00427-8

Ismail F, Kubica EG (1995) Active suppression of chatter in peripheral milling. Part 1. A statistical indicator to evaluate the spindle speed modulation method. Int J Adv Manuf Technol 10(5):299–310. doi:10.1007/BF01178983

Tewani SG, Rouch KE, Walcott BL (1995) A study of cutting process stability of a boring bar with active dynamic absorber. Int J Mach Tools Manuf 35(1):91–108. doi:10.1016/0890-6955(95)80009-3

Adkins CA, Huang ZM, Wong BW, Walcott BL, Rouch KE (1996) Active vibration control using an electromagnetic absorber with two degrees of freedom. Proceedings of IEEE Southeastcon Conference, Tampa, USA, pp 175–178. doi:10.1109/ SECON.1996.510051

Wong BW, Walcott BL, Rouch KE (1995) Active vibration control via electromagnetic dynamic absorbers. Proceedings of IEEE Conference on Control Applications, Albany, USA, pp 868–874. doi:10.1109/CCA.1995.555868

Marra MA, Walcott BL, Rouch KE, Tewani SG (1995) H∞-vibration control for machining using active dynamic absorber technology. Proceedings of the American Control Conference, Seattle, USA, pp 739–743

Mei C (2005) Active regenerative chatter suppression during boring manufacturing process. Robot Comput-Integr Manuf 21(2):153–158. doi:10.1016/ j.rcim.2004.07.011

Wang M, Fei RY (1999) Chatter suppression based on nonlinear vibration characteristic of electrorheological fluids. Int J Mach Tools Manuf 39(12):1925–1934. doi:10.1016/S0890-6955(99)00039-5

Lam AH, Liao WH (2003) Semi-active control of automotive suspension systems with magnetorheological dampers. Int J Veh Des 33(1–3):50–75. doi:10.1504/IJVD.2003.003652

Raymond DW, Elsayed MA. Controllable magneto-rheological fluid-based dampers for drilling. USA Patent 7,036,612

Mei DQ, Kong TR, Li X. An intelligent boring bar with chatter self-suppressing based on magnetorheological fluid. China Patent 200510062179.4

Mei DQ, Kong TR, Shih AJ, Chen ZC (2009) Magnetorheological fluid controlled boring bar for chatter suppression. J Mater Process Technol 209(4):1861–1870. doi:10.1016/j.jmatprotec.2008.04.037

Yang S, Tang HL, Liao BY (1983) Machine tool dynamics. China Machine Press, Beijing (in Chinese)

Chen YD (1988) Mechanical vibration (Linear System). Zhejiang University Press, Hangzhou (in Chinese)

Hoshi T (1984) Analysis and countermeasure on mechanical machining chatter. Shanghai Scientific and Technical Press, Shanghai (in Chinese, translated by Gu CX)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mei, D., Yao, Z., Kong, T. et al. Parameter optimization of time-varying stiffness method for chatter suppression based on magnetorheological fluid-controlled boring bar. Int J Adv Manuf Technol 46, 1071–1083 (2010). https://doi.org/10.1007/s00170-009-2166-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2166-9