Abstract

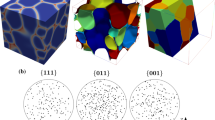

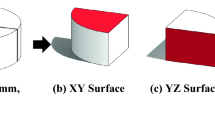

To aid crystal-plasticity finite-element (CPFE) simulation for the forming of micro-components, a VGRAIN system has been developed to generate the microstructure of materials. Based on Voronoi tessellation and probability theory, grains and grain boundaries for micro-materials can be generated. A gamma-distribution function with three physical parameters of a material, which are the average, minimum, and maximum grain sizes, is used to describe the grain-size distribution of the material and a numerical method has been developed to link the gamma-distribution variables and the physical parameters of the material. The distribution of generated virtual gains using the developed VGRAIN system is compared with that of microstructural-examination data for a number of engineering materials, close agreements being obtained for the cases studied. Grain orientations, which are defined using two angles, related to the global coordinate system, have been assigned in the VGRAIN system according to probability theory. The crystal orientations for the virgin and deformed materials are represented using pole figures, so that the grain orientation before and after deformation can be compared and analyzed. The generated virtual microstructure, with grain-orientation information, is then input the commercial FE solver, ABAQUS/CAE, for further pre-processing for CPFE micro-forming simulation. A crystal-viscoplasticity material model for face-centered cubic metals is implemented in the FE code through the used-defined sub-routine, VUMAT/UMAT. CPFE analyses have been carried out to investigate the grain-size and orientation effects on the distortion of formed micro-pins.

Similar content being viewed by others

References

Geiger M, Kleiner M, Eckstein R, Tiesler N, Engel U (2001) Microforming. CIRP Ann 50(2):445–462. doi:10.1016/S0007-8506(07)62991-6

Needleman A (2000) Computational mechanics at the mesoscales. Acta Mater 48:105–124. doi:10.1016/S1359-6454(99)00290-6

Cailletaud G, Forest S, Jeulin D, Feyel F, Galliet I, Mounoury V, Quilici S (2003) Some elements of microstructural mechanics. Comput Mater Sci 27(3):351–374. doi:10.1016/S0927-0256(03)00041-7

Nakamachi E, Hiraiwa K, Morimoto H, Harimoto M (2000) Elastic/crystalline viscoplastic finite element analyses of single- and poly-crystal sheet deformations and their experimental verification. Int J Plast 16(12):1419–1441. doi:10.1016/S0749-6419(99)00092-3

Kovac M, Leon C (2005) Modelling elasto-plastic behaviour of polycrystalline grain structure of steels at mesoscopic level. Nucl Eng Des 235:1939–1950. doi:10.1016/j.nucengdes.2005.05.009

Dao M, Li M (2001) A micromechanics study on strain-localisation-induced fracture initiation in bending using crystal plasticity model. Philos Mag A 8(8):1997–2020. doi:10.1080/01418610108216649

Ren ZY, Zheng QS (2004) Effects of grain sizes, shapes and distribution on minimum size of representative volume element of cubic polycrystals. Mech Mater 36(12):1217–1229. doi:10.1016/j.mechmat.2003.11.002

Zhu HX, Thorpe SM, Windle AH (2001) The geometrical properties of irregular two dimensional Voronoi tessellations. Philos Mag A 81(12):2765–2783

Kobayashi K, Sugihara K (2002) Crystal Voronoi diagram and its applications. Future Generation Comput Syst 18(5):681–692. doi:10.1016/S0167-739X(02)00033-X

Weyer S, Fr¨ohlich A, Riesch-Oppermann H, Cizelj L, Kovaˇc M (2002) Automatic finite element meshing of planar Voronoi tessellations. Eng Fract Mech 69(8):945–958

Zaninetti L (2006) On the large-scale structure of the universe as given by the Voronoi diagrams. Chin J Astron Astrophys 6(4):387–395. doi:10.1088/1009-9271/6/4/01

Zhu B, Asaro RJ, Krysl P, Zhang K, Weertman JR (2006) Effects of grain size distribution on the mechanical response of nanocrystalline metals; part II. Acta Mater 54:3307–3320. doi:10.1016/j.actamat.2006.03.022

Dalla Torre F, Van Swygenhoven H, Victoria M (2002) Nanocrystalline electrodeposited Ni: microstructure and tensile properties. Acta Materialia 50:3957–3970. doi:10.1016/S1359-6454(02)00198-2

Danon A, Servant C, Alamo A, Brachet JC (2003) Heterogeneous austenite grain growth in 9Cr martensitic steel: influence of the heating rate and the austenitization temperature. Mater Sci Eng A 348:122–132. doi:10.1016/S0921-5093(02)00632-9

Fátima Vaz M, Fortes MA (1988) Grain size distribution: the lognormal and the gamma distribution functions. Scr Metall 22:35–40. doi:10.1016/S0036-9748(88)80302-8

Wang C, Liu G, Wang G, Xue W (2007) On the quasi-stationary grain size distribution from two Gamma size distributions in three-dimensional grain growth. Mater Lett 61:4262–4266. doi:10.1016/j.matlet.2007.01.107

Okabe A, Boots B, Sugihara K (1992) Spatial tessellations: concepts and applications of voronoi diagrams. Wiley, New York

Stoyan D, Kendall WS, Mecke J (1987) Stochastic geometry and its application. Wiley, New York

Fortune S 1985, A fast algorithm for polygon containment by translation, Proceedings of the 12th Colloquium on Automata, Languages and Programming, 189-198

Li B, Lin J, Yao X (2002) A novel evolutionary algorithm for determining unified creep damage constitutive equations. Int J Mech Sci 44(5):987–1002. doi:10.1016/S0020-7403(02)00021-8

Cao J, Zhuang W, Wang S, Ho K, Zhang N, Lin J, Dean TA (2009) An integrated crystal plasticity FE system for micro-forming simulation. Int J Multiscale Model 1(1):107–124. doi:10.1142/S1756973709000037

Bunge HJ 1993, Texture analysis in materials science: mathematical methods, Cuvillier Verlag, Gättingen, ISBN 3-928815-81-4.

Taylor GI (1938) Plastic strain in metals. J Inst Met 62:307–324

Hill R, Rice JR (1972) Constitutive analysis of elastic-plastic crystals at arbitrary strain. J Mech Phys Solids 20(6):401–413. doi:10.1016/0022-5096(72)90017-8

Asaro RJ (1983) Crystal plasticity J Appl Mech 50:921

Peirce D, Asaro RJ, Needleman A (1982) Material rate dependence and localized deformation in crystalline solids. Acta Metalialia 31:1951. doi:10.1016/0001-6160(83)90014-7

Harewood FJ, McHugh PE (2007) Comparison of the implicit and explicit finite element methods using crystal plasticity. Comput Mater Sci 39:481–494. doi:10.1016/j.commatsci.2006.08.002

Huang Y (1991) A User-material subroutine incorporating single crystal plasticity in the ABAQUS finite element programme. Harvard University Report No, MECH 178

Krishnan K, Cao J, Dohda K (2007) Study of the size effect on friction conditions in micro-extrusion: part 1. Microextrusion experiments and analysis. ASME J Manufact Sci Eng 129:669–676

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, J., Zhuang, W., Wang, S. et al. Development of a VGRAIN system for CPFE analysis in micro-forming applications. Int J Adv Manuf Technol 47, 981–991 (2010). https://doi.org/10.1007/s00170-009-2135-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2135-3