Abstract

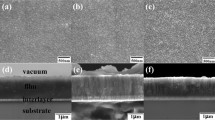

This paper reports on tribological properties of magnetron-sputtered WC–C and chemical vapour-deposited diamond-like carbon films coated onto hard-metal surfaces when sliding on aluminium foil (0.2 mm nominal thickness) at different temperatures. The study addresses the evolution of the coefficient of friction at the interfaces of the coated hard metal and the aluminium foil under dry-lubrication conditions, in a ball-on-disc configuration. The wear mechanisms of the aluminium foil and the damage produced on the coated surfaces due to the sticking of aluminium were evaluated as a function of the deposited coating and the temperature at their interfaces. Aluminium-transfer to WC–C coated hard-metal surfaces during the sliding operation seemed to be a non-continuous process, which appeared after a certain number of sliding cycles. Temperatures above 70°C accelerated the transfer of aluminium to the WC–C tool surfaces. Chemical vapour-deposited diamond-like carbon films hindered the transfer of aluminium to the hard metal even at temperatures of around 125°C. At greater temperatures, an aluminium–aluminium tribosurface is formed at the interface, which increases the wear rate of the foils and rapidly degrades the quality of coatings of the hard-metal surfaces.

Similar content being viewed by others

References

Vollertsen F, Hu Z, Schulze Niehoff H, Theiler C (2004) State of the art in micro forming and investigations in micro deep drawing. J Mats Proc Tech 151:70. doi:10.1016/j.jmatprotec.2004.04.266

Geiger M, Messner A, Enge U (1997) Production of microparts—size effects in bulk metal forming, similarity theory. Prod Eng IV(1):55

Hutchings IM, Wilson S, Alpas AT (2000) Wear of aluminum-based composites. Compr Compos Mater 3:501. doi:10.1016/B0-08-042993-9/00018-8

Zhang J, Alpas AT (1997) Transition between mild and severe wear in aluminium alloys. Acta Mater 45:513. doi:10.1016/S1359-6454(96)00191-7

Straffelini G, Pellizzari M, Molinari A (2004) Influence of load and temperature on the dry sliding behaviour of Al-based meta-matrix-composites against friction material. Wear 256:754. doi:10.1016/S0043-1648(03)00529-5

S-P LO, Lin Y-Y (2002) An investigation of sticking behaviour on the chip–tool interface using thermo-elastic-plastic finite element method. J Mats Proc Tech 121:285. doi:10.1016/S0924-0136(01)01259-6

Kishawy HA, Dumitrescu M, Ng E-G, Elbestawi MA (2005) Effect of coolant strategy on tool performance, chip morphology and surface quality during high-speed machining of A356 aluminium alloy. Int J Mach Tools Manuf 45:219. doi:10.1016/j.ijmachtools.2004.07.003

Mitterer C, Holler F, Reitberger D, Badisch E, Stoiber M, Lugmair C, Nöbauer R, Müler T, Kulmer R (2003) Industrial applications of PACVD hard coatings. Surf Coat Tech 163–164:716. doi:10.1016/S0257-8972(02)00685-0

Rodríguez RJ, García JA, Martinez R, Lerga B, Rico M, Fuentes GG, Guette A, Labruguere C, Lahaye M (2004) Tribological metal–carbon coatings deposited by PVD magnetron sputtering. Appl Surf Sci 235:53. doi:10.1016/j.apsusc.2004.05.124

Podgornik B, Hogmark S, Pezdirnik J (2004) Comparison between different test methods for evaluation of galling properties of surface engineered tool surfaces. Wear 257:843. doi:10.1016/j.wear.2004.05.005

Arndt M, Kacsich T (2003) Performance of new AlTiN coatings in dry and high speed cutting. Surf Coat Tech 163–164:674. doi:10.1016/S0257-8972(02)00694-1

Ali Erdemir (2004) Genesis of superlow friction and wear in diamondlike carbon films. Tribology Int 37:1005–1012. doi:10.1016/j.triboint.2004.07.018

Carlsson P, Olsson M (2006) PVD coatings for sheet metal forming processes—a tribological evaluation. Surf Coat Tech 200:4654. doi:10.1016/j.surfcoat.2004.10.127

Harlin P, Carlsson P, Bexell U, Olsson M (2006) Influence of surface roughness of PVD coatings on tribological performance in sliding contacts. Surf Coat Tech 201:4253. doi:10.1016/j.surfcoat.2006.08.103

Marukawa M, Takeuchi S (2003) Evaluation of tribological properties of DLC films used in sheet forming of aluminum sheet. Surf Coat Tech 163–164:561. doi:10.1016/S0257-8972(02)00624-2

Berger M, Hogmark S (2002) Tribological properties of selected PVD coatings when slid against ductile materials. Wear 252:557–565. doi:10.1016/S0043-1648(02)00011-X

Fuentes GG, Díaz de Cerio MJ, Rodriguez R, Avelar-Batista JC, Spain E, Housden J, Yi Qin (2006) Study on the sliding of aluminium thin foils on the PVD-coated carbide forming-tools during micro-forming. J Mater Proc Tech 177:644. doi:10.1016/j.jmatprotec.2006.03.235

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Díaz de Cerio, M.J., Fuentes, G.G., Martínez, R. et al. Temperature-dependent contact phenomena of PVD- and CVD-deposited DLC films sliding on the thin aluminium foil. Int J Adv Manuf Technol 47, 931–936 (2010). https://doi.org/10.1007/s00170-009-2130-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2130-8