Abstract

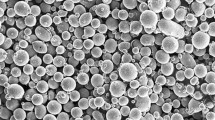

Laser-engineered net shaping, referred to as LENSTM process, is an additive manufacturing technique for building metallic parts, layer by layer, by direct deposition of metal powders in a melt pool created by a focused laser beam. The process involves rapid melting and solidification of a controlled amount of injected metal powders as a laser beam scans over each layer building the structure from the bottom to the top. Due to its unique capability to deposit precise amounts of powder material at a desired location, the LENSTM process finds potential application in rapid tooling, prototyping, precision repair work, and manufacture of complex, intricate components with varying compositions. The peak temperature and thermal cycle experienced by each layer influence the final mechanical properties and dimensional accuracy of the part. An understanding and quantitative knowledge of the peak temperature, melt pool dimensions, and thermal cycles experienced in the deposited layers are essential for a priori selection of the process parameters in LENSTM technique. It is important to ensure that the deposited layers have the desired dimensions, good interlayer bonding, and requisite mechanical properties. In an attempt to understand the process parameters to be used in achieving the desired nature of deposition, a three-dimensional model is developed based on finite element method to numerically simulate heat transfer phenomenon in LENSTM process considering deposition of SS316 powders on a substrate of the same material. The computed temperature profiles are first validated with experimental results reported in the literature. The influence of process parameters on peak temperature, thermal cycles, and melt pool dimensions are studied subsequently. The continuous movement of laser and synchronized activation of elements depicting addition of powder particles are incorporated through an externally written user subroutine and using the element deactivation and activation features in the commercial finite element software ABAQUS 6.7. A unique non-dimensional parameter specific to LENSTM process is defined considering the combined influence of process parameters and material properties. The non-dimensional parameter is further used to serve as a guideline for the selection of appropriate process parameters that can result in a steady melt pool dimension, thereby ensuring a target layer width with good interlayer bonding.

Similar content being viewed by others

References

Griffith M, Keicher D, Atwood C, Romero J, Smugeresky J, Harwell L, Greene D (1996) Freeform fabrication of metallic components using laser engineered net shaping. Solid Freeform Fabrication Proceedings, p 125–132

Keicher D, Smugeresky J, Romero J, Griffith M, Harwell L (1997) Using the laser engineered net shaping process to produce complex components from a CAD solid model. Proc SPIE 2993:91–97. doi:10.1117/12.270018

Atwood C, Griffith M, Harwell L, Schlienger M, Ensz M, Smugeresky J, Romero J, Greene D, Reckaway D (1998) Laser engineered net shaping (LENS): a tool for direct fabrication of metal parts. Proceedings of the ICALEO, pp E-1–7

Griffith M, Schlienger M, Harwell L, Oliver M, Baldwin M, Ensz M, Smugeresky J, Essien M, Brooks J, Robino C, Hofmeister W, Wert M, Nelson D (1999) Understanding thermal behavior in the LENS™ process. J Mater Des 20(2/3):107–113

Griffith M, Ensz M, Puskar J, Robino C, Brooks J, Philliber J, Smugeresky J, Hofmeister W (2000) Understanding the microstructure and properties of components fabricated by laser engineered net shaping. Solid Freeform Add Fabr, MRS Symp Proc 625:9–20

Hofmeister W, Philliber J, Smugeresky J, Wert M, Ensz M, Griffith M (1999) Investigation of solidification in the laser engineered net shaping process. J Met 7:51–57

Vasinonta A, Beuth J, Griffith M (2001) A process map for consistent build conditions in the solid freeform fabrication of thin-walled structures. J Manuf Sci Eng 123(4):615–622. doi:10.1115/1.1370497

Costa L, Vilar R, Reti T, Deus A (2005) Rapid tooling by laser powder deposition: process simulation using finite element analysis. Acta Mater 53(14):3987–3999. doi:10.1016/j.actamat.2005.05.003

Ye R, Smugeresky J, Zheng B, Zhou Y, Lavernia E (2006) Numerical modeling of the thermal behavior during the LENS process. Mater Sci Eng A 428:47–53. doi:10.1016/j.msea.2006.04.079

Wang L, Felicelli S (2006) Analysis of thermal phenomena in LENS deposition. Mater Sci Eng A 435–436:625–631. doi:10.1016/j.msea.2006.07.087

Wang L, Felicelli S, Gooroochurn Y, Wang P, Horstemeyer M (2008) Optimization of LENS process for steady molten pool size. Mater Sci Eng A 474(1/2):148–156

Grujicic M, Hu Y, Fadel G, Keicher D (2001) Optimization of the LENS rapid fabrication process for in-flight melting of feed powder. J Mater Synth Process 9(5):223–233. doi:10.1023/A:1015262032445

Peyre P, Aubry P, Fabbro R, Neveu R, Longuet A (2008) Analytical and numerical modeling of the direct metal deposition laser process. J Phys D Appl Phys 4:1–10

ABAQUS ref. manual (2001) Chp. 6—heat transfer analysis. Hibbitt, Karlson & Sorensen, Pawtucket, RI

De A, DebRoy T (2004) A smart model to determine effective thermal conductivity and viscosity in the weld pool. J Appl Phys 95:5230–5240. doi:10.1063/1.1695593

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neela, V., De, A. Three-dimensional heat transfer analysis of LENSTM process using finite element method. Int J Adv Manuf Technol 45, 935–943 (2009). https://doi.org/10.1007/s00170-009-2024-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2024-9