Abstract

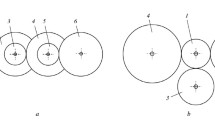

Grating disks of a microrotary encoder are developed to measure the rotational accuracy of microgears. In gear engagement, transmission error plays an important role to grasp the meshing performance of gear pairs. For measurement of transmission error of microgears, it is necessary to utilize a couple of microrotary encoders whose diameters are smaller than the reference diameter of microgears to be measured. The designed grating disk has a diameter of 1 mm, and the number of gratings is up to 1,000. It is manufactured with photo-lithography method on trial, and the grating patterns are successfully achieved homogeneously. The accuracy of the pitch and the line width is enough for realizing grating disks of a microrotary encoder.

Similar content being viewed by others

References

Bhushan B (ed) (2004) Handbook of Nanotechnology. Springer, Germany

Johnstone RW, Parameswaran M (2004) An introduction to surface-micromachining. Kluwer, USA

Horiuchi T, Furuuchi Y, Nakamura R, Hirota K (2006) Micro-gear fabrication using optical projection lithography on copper-clad plastic substrates and electroplating of nickel. Microelectric Eng 83:1316–1320. doi:10.1016/j.mee.2006.01.083

Gosh G (2003) Gear metrology. CIRP Annals 52(2):1–37

Fujio H, Kubo A, Saitoh Y, Suzuki M, Tochimoto S, Hanaki H, Honda T (1994) Laser holographic measurement of tooth flank form of cylindrical involute gear. ASME. J Mech Des 116:721–729. doi:10.1115/1.2919442

Gao W, Furukawa M, Kiyono S, Yamazaki H (2004) Cutting error measurement of flexspline gears of harmonic speed reducers using laser probes. Precis Eng 28:358–363. doi:10.1016/j.precisioneng.2003.12.001

Okuyama E, Kiyono S, Moritoki H (1994) Investigation of an optical noncontact gear geometry measurement system: measurement of pitch errors and tooth profiles. Precis Eng 16(2):117–123

Kurokawa S, Ariura Y (2004) Development of single flank gear testing machine and the influence of measurement resolution on observation of spur and helical gear engagement under load. Proc. of the Int. Symposium on Technology of Machinery Systems Design 2004. Korea (South) 1:32–37

ISO (1995) Cylindrical gears—ISO system of accuracy— Part 1: definitions and allowable values of deviations relevant to corresponding flanks of gear teeth. ISO-1328-1, pp 6–7

Hochmann D, Houser DR (1994) An experimental test stand for measurements on loaded parallel axis gears. Proc. of Int. Gearing Conference in Newcastle U.K., pp 401–405

Smith JD, Echeverria-Villagomez JS (1990) Comparing encoder and accelerometer measurement of transmission error or torsion vibration. Proc. Int. Mech. Eng. C404–027, pp 43–49.

Kato S, Kubo A, Tanaka K (1993) Measurement of transmission error of gears using laser velocimeters. Trans. of the JSME, 59–564, C, pp 2552–2557

Jauregui JC, Lozano (1994) Gear transmission error measurement through holography. A Proc. Int. Gearing Conference in Newcastle U.K., pp 359–362

Waits CM, Morgan B, Kastantin M, Ghodssi R (2005) Microfabrication of 3D silicon MEMS structures using gray-scale lithography and deep reactive ion etching. Sensors Actuator A 119:245–253

Bourouina T, Masuzawa T, Fujita H (2004) The MEMSNAS process: microloading effect for micromachining 3D structures of nearly all shapes. J Microelectromech Syst 13(2):190–199

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kurokawa, S., Ariura, Y. Development of a grating disk of a microrotary encoder for measurement of meshing accuracy of microgears. Int J Adv Manuf Technol 46, 931–944 (2010). https://doi.org/10.1007/s00170-008-1921-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1921-7