Abstract

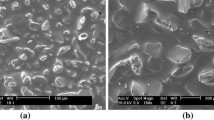

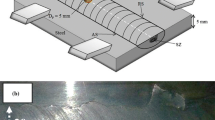

This research studies the characteristics of aluminum 2024, 304 stainless steel, and 1018 steel during lapping with three different types of abrasives, namely, garnet, silicon carbide, and white aluminum oxide, through detailed experimental analysis. Specifically, the effects of different abrasives on material removal rate and surface finish were evaluated. It was found that silicon carbide and white aluminum oxide abrasives removed more material per minute than garnet. A higher mean frictional force and mean coefficient of friction were obtained in aluminum lapped with SiC and white Al2O3 abrasives, and a lower mean frictional force was obtained in 304 stainless steel lapped with SiC. From geometric and energy-dispersive spectroscopy analysis obtained using scanning electron microscopy, it was confirmed that some abrasives became embedded into the lapped metal substrates. No burn was observed on the lapped samples, and scratches and unfinished lapped parts were observed mainly in 304 stainless steel. In order to determine the quantitative influence of each variable, an analysis of variance was performed. It was found that the main effects of abrasive types, size of abrasives, and type of work material had statistically significant influence on material rate and surface finish. In addition, there was a highly significant two-way interaction between abrasives and workpiece.

Similar content being viewed by others

References

Lynah P, Hoffman PR (1989) Lapping. ASM Handb 16:492–505

Le X, Peterson ML (1999) Material removal rate in flat lapping. J Manuf Process 16(1):71–78

Davis JR (1994) Surface engineering of carbon and alloy steels. ASM Handbook 5:701–710

Deshpande LS (2005) Influence of abrasive material properties on the surface generated in flat lapping. Published master’s thesis, University of Oklahoma, Norman, OK, pp 19–30

Garzino-Demo GA, Lama FL (1994) Friction and wear of uncoated or SiO2-coated 329 stainless and of uncoated or AlN-coated aluminum surfaces. Surf Coat Technol 68/69:507–511

Jiandong Y, Changgen R, Changxing W (1998) Theoretical analyses movement between press head and press disc in lapping. Proceeding of SPIE—The International Society for Optical Engineering, pp 225–228

Ashkerov YV (1992) Role of frictional forces in grinding and polishing processes in machines that operate by the lapping method. Sov J Opt Technol 59(4):250–254

Schmitz TL, Action JE, Ziegert JC, Sawyer GW (2005) The difficulty of measuring low friction: uncertainty analysis for friction coefficient measurements. J Tribol, Transactions of the ASME 127(3):673–677

Awtar S, Craig KC (2004) Electromagnetic coupling in a dc motor and tachometer assembly. J Dyn Syst Meas Control: Transactions of the ASME 126:684–691

Singer S, Appelbaum J (1993) Starting characteristics of direct current motors powered by solar cells. IEEE Trans Energy Convers 8(1):47–53

Rabinowicz E (1966) Friction and wear of material, 2nd edn. Wiley, New York, pp 52–79, 85, 95–123

Kalpakjian S, Schmid SR (2006) Manufacturing engineering and technology, 5th edn. Pearson Prentice Hall, New Jersey, p 621, 1043

Deshpande LS, Raman S, Sunanta O, Agbaraji C (2008) Observations in the flat lapping of stainless steel and bronze. Wear 265(1–2):105–116

Harris DC (2007) Quantitative chemical analysis, 7th edn. Freeman, New York, pp AP 20–27

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Agbaraji, C., Raman, S. Basic observations in the flat lapping of aluminum and steels using standard abrasives. Int J Adv Manuf Technol 44, 293–305 (2009). https://doi.org/10.1007/s00170-008-1827-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1827-4