Abstract

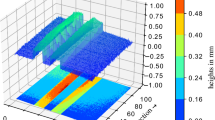

Although image-based inspection has been applied to a wide range of industrial applications, inspection accuracy remains a challenging issue due to the complexity involved in industrial inspection. The common method adopted in industry is to use a qualified image as a template image to inspect each live image on a pixel-by-pixel basis. In this paper, a tolerance method is presented to replace the template image method. The said tolerance is formed by two indices computed from a sample image, instead of using the whole image for inspection. To ensure an accurate tolerance zone, a neural networks method is used to take the noise and uncertainties in the images under inspection into consideration. To improve neural networks training speed, the Taguchi method is adopted to select a minimum number of the sample images needed for training. Once a tolerance zone is obtained, live images are inspected against it. If the indices of a live image fall inside the tolerance zone, the part is regarded as good, otherwise defective. Three examples are given: one for auto part inspection, one for label inspection, and one for machining part inspection. The inspection accuracy achieved is above 94%.

Similar content being viewed by others

References

Lee KH, Park H (2000) Automated inspection planning of free-form shape parts by laser scanning. Robot Comput Integr Manuf 16:201–210. doi:10.1016/S0736-5845(99)00060-5

Tseng C, Lai M, Lee P (2006) Image inspection system for defect detection of multilayer ceramic capacitors. Proceedings, 2006 International Conference on Intelligent Information Hiding and Multimedia Signal Processing, pp 659–662

Liu H, Han J (2006) Defect detection in textiles using optimal Gabor Wavelet filter. Proceedings of the World Congress on Intelligent Control and Automation pp. 10005–10007

Furtler J, Bodenstorfer E, Mayer KJ, Brodersen J, Heiss D, Penz H, Eckel C, Gravogl K, Nachtnebel H (2007) High-performance camera module for fast quality inspection in industrial printing applications. Proceedings of SPIE-IS and T Electronic Imaging—Machine Vision Applications in Industrial Inspection XV: 65030J

Nagarajan R, Yaacob S, Pandian P, Karthigayan M, Hj Amin S, Khalid M (2007) A real time marking inspection scheme for semiconductor industries. Int J Adv Manuf Technol 34(9–10):926–932. doi:10.1007/s00170-006-0669-1

Bayro-Corrochano E (1993) Review of automated visual inspection. 1983 to 1993—Part I: Conventional approaches. SPIE Proc Intell Robots Comput Vis XII 2055:128–158

Moganti M, Ercal F, Dagli CH, Tsunekawa S (1996) Automatic PCB inspection algorithms: a survey. J Comput Vis Image Underst 63(2):287–313. doi:10.1006/cviu.1996.0020

Gonzalez RC, Woods RE, Eddins SL (2004) Digital image processing using MATLAB. Prentice Hall, NJ

Raus M, Brenner O, Ameling W (1994) Neural quality inspection in industrial compact disc print stations. Proceedings of Second International Conference on Intelligent Systems Engineering, pp. 154–158

Karayiannis YA, Stojanovic R, Mitropoulos P, Koulamas C, Stouraitis T, Koubias S, Papadopoulos G (1999) Defect detection and classification on web textile fabric using multi-resolution decomposition and neural networks. Proc IEEE Int Conf Electron Circuits Syst 2:765–768

Sankaran V, Chartrand B, Lillard DLH, Embrechts MJ, Kraft RP (1995) Automated inspection of solder joints—a neural network approach. Proceedings of Electronics Manufacturing Technology Symposium, pp. 232–237

Dreyfus G (2005) Neural networks—methodology and applications. Springer, Berlin

Taguchi G (1986) Introduction to quality engineering. Krauss, New York

Taguchi G (1993) Taguchi on robust technology development. American Society of Mechanical, New York

Chan L, Ma C, Goh TN (2003) Orthogonal arrays for experiments with lean designs. J Qual Technol 35(2):123–138

Nguyen N (1996) A note on the construction of near-orthogonal arrays with mixed levels and economic run size. Technometrics 38(3):279–283. doi:10.2307/1270612

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, H., Xi, F., Ghasempoor, A. et al. A tolerance method for industrial image-based inspection. Int J Adv Manuf Technol 43, 1223–1234 (2009). https://doi.org/10.1007/s00170-008-1801-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1801-1