Abstract

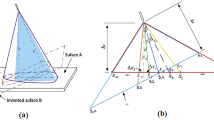

Magnetically impelled arc butt (MIAB) welding is a unique forge welding process in which an arc is drawn in the gap between the two tubes to be welded in order to raise them to a high temperature to allow forging to form a solid-state weld. In this case, the arc is rotated with a high speed around the weld line by an electromagnetic force resulting from the interaction of the magnetic field and the arc current. This paper presents the details of the results and the conclusions of the experimental trials conducted on the MIAB module designed and developed based on the principle. Further, nonlinear electromagnetic analysis has been performed to determine the magnetic field and electromagnetic force distribution in MIAB process using finite element package ANSYS. Typical results of this analysis pertaining to magnetic field are compared with the experimental data for steel tubes (outer diameter 47 mm and thickness of 2 mm). It is observed that the results from finite element analysis and the experimental trials are in excellent agreement. The proposed three-dimensional finite element method model for electromagnetic force distribution facilitates comprehensive understanding of the arc rotation process in MIAB welding.

Similar content being viewed by others

References

Ganowski F-J (1974) The magnet arc welding process. Weld Metal Fabr 42:206–213 (June)

Georgescu V, Iordachescu D, Geogescu B (2000) Pneumatically operated equipment for pressure welding in magnetic forces field. Dunarea De Jos, University of Galati, Romania

Glickstein SS (1979) Arc modelling for welding analysis. Westinghouse–Bettis Atomic Power Laboratory. West Mifflin, USA, Paper 5, pp 1–16

Kim JW, Choi DH (2003) A study on the numerical analysis of magnetic flux density distribution by a solenoid for magnetically impelled arc but welding. . Proc Inst Mech Eng Part B: J Eng Manuf 217:1401–1407

Arungalai Vendan S, Manoharan S, Buvanashekaran G, Nagamani C (2008) Simulation of magnetic flux distribution for magnetically impelled arc butt welding of steel pipes. Int J Multidisc Model Mater Struct 222:1783–1790

Arungalai Vendan S, Manoharan S, Buvanashekaran G, Nagamani C (2008) Magnetic flux distribution modeling of magnetically impelled arc butt welding of steel tubes using finite element analysis. Inst Mech Eng, Part C: J Mech Eng Sci (in press)

Georgescu V, Iordachescu D (1998–2000) Original magnetizing systems for ROTARC welding. The Annals of Dunarea de Jos, University of Galati, pp 10–14 (ISSN 1221-4639)

Schlebeck E (1978) Welding with a magnetically moved arc (MBL welding): a new means of rationalization. Proceedings of Welding Institute Conference on Advances in Welding Processes. Harrogate, pp 249–256

Kuchuk-Yatsenko SI, Kachinsky VS, Ignatenko VYu (2002) Magnetically-impelled arc butt welding of thick-walled pipes. Paton Weld J 7:24–28

Kachinskiy VS, Krivenko VG, Ignatenko VYu (2002) Magnetically impelled arc butt welding of hollow and solid parts. Commission III Doc IIW-1564-02, pp 49–56

Johnson KI, Carter AW, Dinsdale WO, Threadgill PL, Wright JA (1979) The magnetically impelled arc butt welding of mild steel tubing. Weld J 59(11):17–27

Tagaki K, Arakida F, Miyamori H, Ozawa M (1986) Arc rotating phenomena in rotating arc butt welding of steel pipes. J Jap Weld Soc 4(2):305–311 (in Japanese)

Mori S, Yasuda K (1990) Magnetically-impelled arc butt welding of aluminum pipes. Trans Jpn Weld Soc 21(1):3–10

Schmidt N (1986) Magnetic field distribution during pressure welding of magnetic and non-magnetic components with a magnetically controlled arc, welding and cutting. 10/1986, pp E169–E171

Sato K, Ioka O (1991) An experimental study of rotational behavior of the arc during magnetically impelled arc butt welding. Weld Int 5(1):5–10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vendan, S.A., Manoharan, S., Buvanashekaran, G. et al. Development of a MIAB welding module and experimental analysis of rotational behavior of arc—simulation of electromagnetic force distribution during MIAB welding of steel pipes using finite element analysis. Int J Adv Manuf Technol 43, 1144–1156 (2009). https://doi.org/10.1007/s00170-008-1793-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1793-x