Abstract

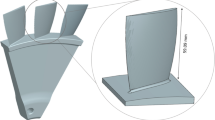

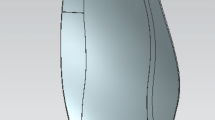

This paper aims at developing a novel spiral machining technique for four- or five-axis milling of blades. The main contributions are twofold. First, detailed algorithms are presented to model the blade surface with the idea that it can be separated into four patches, i.e., the pressure surface, the suction surface, the leading edge surface, and the trailing edge surface. The G1 continuity across the boundary of each patch is considered. Second, based on the four patches modeled, the key routine of a new spiral machining method is further addressed in detail. It is carried out by machining the pressure and suction surfaces actually whereas passing by the leading and trailing edges in air cut. Experimental results show that the proposed methods can improve the machining quality and avoid overcut near the leading and trailing edges.

Similar content being viewed by others

Reference

Hsu TH, Lai JY, Ueng WD (2006) On the development of airfoil section inspection and analysis technique. Int J Adv Manuf Technol 30:129–140 doi:10.1007/s00170-005-0046-5

Zhu D, Xu HY (2002) Improvement of electrochemical machining accuracy by using dual pole tool. J Mater Process Technol 129:15–18 doi:10.1016/S0924-0136(02)00567-8

Yang DY, Lee NK, Yoon JH (1993) A three-dimensional simulation of isothermal turbine blade forging by the rigid-viscoplastic finite-element method. J Mater Eng Perform 2:119–124 doi:10.1007/BF02649684

Sijie Y, Yunfei Z, Fangyu P, Xide L (2004) Research on the localisation of the workpieces with large sculptured surfaces in NC machining. Int J Adv Manuf Technol 23:429–435 doi:10.1007/s00170-003-1897-2

Langeron JM, Duc E, Lartigue C, Bourdet P (2004) A new format for 5-axis tool path computation, using B spline curves. Comput Aided Des 36:1219–1229 doi:10.1016/j.cad.2003.12.002

Tournier C, Duc E (2005) Iso-scallop tool path generation in 5-axis milling. Int J Adv Manuf Technol 25:867–875 doi:10.1007/s00170-003-2054-7

Choi BK, Jerard RB (1999) Sculptured surface machining—theory and application. Kluwer Academic, Dordrecht

Roman A, Bedi S, Ismail F (2006) Three-half and half-axis patch-by-patch NC machining of sculptured surfaces. Int J Adv Manuf Technol 29:524–531

Choi YK, Banerjee A (2007) Tool path generation and tolerance analysis for free-form surfaces. Int J Mach Tools Manuf 47:689–696 doi:10.1016/j.ijmachtools.2006.04.014

Bentamy A, Guibault F, Trepanier JY (2005) Cross-sectional design with curvature constraints. Comput Aided Des 37:1499–1508 doi:10.1016/j.cad.2005.03.005

Kjellander JAP (1983) Smoothing of cubic parametric splines. Comput Aided Des 15:175–179 doi:10.1016/0010-4485(83)90085-4

Poliakoff JF, Wong YK, Thomas PD (1999) An automated curve fairing algorithm for cubic B-spline curves. J Comput Appl Math 102:73–85 doi:10.1016/S0377-0427(98)00209-X

Zhang C, Zhang P, Cheng F (2001) Fairing spline curves and surfaces by minimizing energy. Comput Aided Des 33:913–923 doi:10.1016/S0010-4485(00)00114-7

Bai Y, Zhang DH, Ren JX, Liu WW, Gu XM (2003) High quality geometric modeling of blade. Mech Sci Tech 22:447–449 in Chinese

Bobrow JE (1985) NC machine tool path generation from CSG part representations. Comput Aided Des 17:69–76 doi:10.1016/0010-4485(85)90248-9

Huang Y, Oliver JH (1994) Non-constant parameter NC tool path generation on sculptured surfaces. Int J Adv Manuf Technol 9:281–290 doi:10.1007/BF01781282

Loney GC, Ozsoy TM (1987) NC machining of free form surfaces. Comput Aided Des 19:85–90 doi:10.1016/S0010-4485(87)80050-7

Elber G, Cohen E (1994) Tool path generation for freeform surface models. Comput Aided Des 26:490–496 doi:10.1016/0010-4485(94)90070-1

Suresh K, Yang DC (1994) Constant scallop-height machining of freeform surfaces. J Eng Ind 116:253–259 doi:10.1115/1.2901938

You CF, Sheen BT, Lin TK (2001) Robust spiral tool-path generation for arbitrary pockets. Int J Adv Manuf Technol 17:181–188 doi:10.1007/PL00003944

Bieterman MB, Sandstrom DR (2003) A curvilinear tool-path method for pocket machining. J Manuf Sci Eng 125:709–715 doi:10.1115/1.1596579

Chuang JJ, Yang DCH (2007) A Laplace-based spiral contouring method for general pocket machining. Int J Adv Manuf Technol 34:714–723 doi:10.1007/s00170-006-0648-6

Kim BH, Choi BK (2000) Guide surface based tool path generation in 3-axis milling: an extension of the guide plane method. Comput Aided Des 32:191–199 doi:10.1016/S0010-4485(99)00086-X

Lee E (2003) Contour offset approach to spiral tool path generation with constant scallop height. Comput Aided Des 35:511–518 doi:10.1016/S0010-4485(01)00185-3

Sun YW, Guo DM, Jia ZY (2006) Spiral cutting operation strategy for machining of sculptured surfaces by conformal map approach. J Mater Process Technol 180:74–82 doi:10.1016/j.jmatprotec.2006.05.004

Bai Y, Zhang DH, Liu WW, Shi YY, Wang ZQ (2003) An efficient method for four-axis spiral NC programming of blade parts. Mech Sci Tech 22:177–182 in Chinese

Shan CW, Zhang DH, Liu WW, Bai Y (2005) Track programming for the spiral machining of the blade with boundaries. China Mech Eng 16:1629–1632 in Chinese

Piegl L, Tiller W (1997) The NURBS book,, 2nd edn. Springer, New York

Piegl L, Tiller W (1999) Cross-sectional design with boundary constraints. Eng Comput 15:171–180 doi:10.1007/s003660050012

Zhou J, Zhou YH (2002) Technology of NC machining. National Defence Industry Press, Beijing (in Chinese)

Lee YS (1998) Non-isoparametric tool path planning by machining strip evaluation for 5-axis sculptured surface machining. Comput Aided Des 30:559–570 doi:10.1016/S0010-4485(98)00822-7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shan, CW., Zhang, DH., Liu, WW. et al. A novel spiral machining approach for blades modeled with four patches. Int J Adv Manuf Technol 43, 563–572 (2009). https://doi.org/10.1007/s00170-008-1725-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1725-9