Abstract

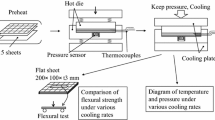

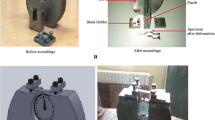

The present study aimed at investigating the effect of temperature on the spring back of cellulose-based sheets in hot pressing through experimental and numerical analysis. Thus, hot pressing process was applied to form cellulose-based sheet into a ring with U-shape cross section. Mechanical properties of the sheets under different time, temperature, and moisture-content conditions were obtained using experimental tests. Based on viscoelastic model, the hot pressing of cellulose-based sheets was successfully simulated using the data obtained from the material tests. The spring back of the parts during a time span of 10,000 s after opening of the die was obtained based on experimental tests and finite element simulation. The effects of temperature of the process and stress relaxation on the spring back were also investigated and the material behavior was also discussed. Simulation results conformed to the experiments, indicating that the approach is capable of accurately predicting the spring back of cellulose-based sheets in hot pressing.

Similar content being viewed by others

References

Golzar M, Alamati B (2006) Material constants of cellulose in bending forming and hot-pressing, 27th International Symposium of Polymer Composite Materials, Riso, Denmark

Hearmon RFS (1953) The elastic and plastic properties of natural wood and paper. In: Meredith R (ed) North. Holl. Publ. Co. Amsterdam, pp. 19–47

Salmen L (1984) Viscoelastic properties of in-situ lignin under water-saturated conditions. J Math Sci 19:3090–3096 doi:10.1007/BF01026988

Salmen L, Kolseth P, deRuvo A (1985) Modeling the softening behavior of wood fibers. J. Pulp Pap Sci 11(4):102–107

Sulzberger PH (1948) The effect of temperature on strength properties of wood, plywood and glued joints at various moisture contents. C. S. I. R. O., Div. For. Prod., South Melbourne, Australia

Sulzberger PH (1953) The effect of temperature on the strength of wood. Aeron. Res. Cons. Comm. Rep. ACA-46, Melbourne

Wolcott MP (1989) Modeling viscoelastic cellular materials for the pressing of wood composites. PhD. Dissertation, V.P.I. & S.U., Blacksburg, VA, USA

Maksimov RD, Mochalov VP, Sokolov EA (1976) Influence of temperature and humidity on the creep of polymer materials. J Mech Compos Mater 12:562–567

Ishisaka A, Kawagoe M (2004) Examination of time—water content superposition on the dynamic viscoelasticity of moistened polyamide 6 and epoxy. J Appl Polym Sci 93:560–567 doi:10.1002/app.20465

Remond R, Passard J, Perre P (2007) The effect of temperature and moisture content on the mechanical behavior of wood: a comprehensive model applied to drying and bending. Eur J Mech A Solids 26:558–582

deLorenzi HG, Nied HF (1987) Blow moulding and thermoforming of plastics: finite element modelling. Compos Struct 26:197–206 doi:10.1016/0045-7949(87)90250-1

DeLorenzi HG, Nied HF (1999) Finite element simulation of thermoforming and blow moulding. In: (ed) Modeling of polymer processing. Cart Hanser, Munich, pp 117–171

Nied HF, Taylor SA, deLorenzi HG (1990) Three-dimensional finite element simulation of thermoforming. Polym Eng Sci 30:1316–1320 doi:10.1002/pen.760302009

Warby MK, Whiteman JR, Jiang W-G, Warwick P, Wright T (2003) Finite element simulation of thermoforming processes for polymer sheets. J. Math Comput Simul 61:209–218 doi:10.1016/S0378-4754(02)00077-0

Bendler JT, LeGrand DG, OLszewski WV (2002) Phenomenology of plastic recovery in high polymer glasses. J Polym 43:389–394 doi:10.1016/S0032-3861(01)00525-0

DeHoff PH, Anusavice KL (2004) Shear stress relaxation of dental ceramics determined from creep behaviour. Journal of Dental Materials 20:717–725

Makradi A, Belouettar S, Ahzi S, Puissant S (2007) Thermoforming process of amorphous polymeric sheets: modeling and finite element simulations. J Appl Polym Sci 106:1718–1724 doi:10.1002/app.26869

Barry CH, McPherson BJ, Medland CJ, Mullineux AJ (2005) Impact of environmental condition on the performance of cartonboard skillets. Packag Technol Sci 18:225–241 doi:10.1002/pts.689

Golzar M, Ghaderi A (2007) Spring back in cellulose sheet forming. Tehran International Congress on Manufacturing Engineering (TICME2007)

Lin CR, Chen RH, Hung C (2002) The characterization and finite-element analysis of polymer under hot pressing. Int J Adv Manuf Technol 20:230–235 doi:10.1007/s001700200219

Li F, Larock RC, Otaigbe JU (2000) Fish oil thermosetting polymers: creep and recovery. J Polym 41:4849–4862 doi:10.1016/S0032-3861(99)00702-8

Pegoretti A, Guardini A, Migliaresi C, Ricco T (2000) Recovery of post-yielding deformation in semicrystalline poly(ethylene-terephthalate). J Polym 41:1857–1864 doi:10.1016/S0032-3861(99)00333-X

Pegoretti A, Pandini S, Ricco T (2006) Strain recovery of post-yield compressed semicrystalline poly(butylenes terephthalate). J Polym 47:5862–5870 doi:10.1016/j.polymer.2006.06.020

IEC 60641, Part 1, 2, and 3 (1992) Specification for Pressboard and Presspaper for Electrical Purposes

Nevel TP (1985) Cellulose chemistry and its applications. Ellis Horwood, UK

Kollmann F, Cote W (1968) Principle of wood science and technology, vol. 2, solid woods. Springer-Verlag, Berlin, Germany

ISO 178 (1993) Plastics—determination of flexural properties. ISO, Geneva, Switzerland

Lakes RS (1999) Viscoelastic solids. CRC, Florida

Beer FP, Johnston ER (2002) Mechanics of materials. McGraw-Hill: New York. (International Student Edition

Krishnamachari SI (1993) Applied stress analyses of plastics: Part 5. Applied viscoelasticity. Van Nostrand Rainhold: New York

Crawford RJ (1998) Plastics engineering. Butterworth Heinemann, UK (3rd edn)

Shaw MT, Macknight WJ (2005) Introduction to polymer viscoelasticity. Wiley, New York

Ward IM, Sweeney J (2004) An introduction to the mechanical properties of solid polymers. Wiley, New York

PeckBending EC (1957) Solid wood to form. Agriculture Handbook No. 125. USDA, USA

Malony TM (1977) Modern flakeboard and dry-process fiberboard manufacturing. Forest Products Society, Madison, WI

Kamke FA, Casey LJ (1988) Gas pressure and temperature in the mat during flakeboard manufacture. For Prod J 38(6):38–44

Suchsland O (1962) The density distribution of flakeboards, Michigan Agricultural Experiment Station Quarterly Bulletin Michigan State University 45(1):104–121

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golzar, M., Ghaderi, A. Effect of temperature on the spring back of cellulose-based sheet in hot pressing. Int J Adv Manuf Technol 42, 633–642 (2009). https://doi.org/10.1007/s00170-008-1626-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1626-y