Abstract

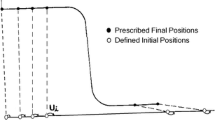

Forward flow forming of tubes have been simulated using an explicit commercial finite element program. Variation of contact geometry considering plastic flow has been calculated based on the proposed criterion. Also flow formability of tube materials have been calculated during forward flow-forming process. Contact geometry simulation results as the variation of S-to-L ratios with feed rates and two attack angles have been compared with outcomes of geometrically based equations. The effects of attack angles and feed rates on the flow formability have been also evaluated. The simulation results have been compared with existing experimental results and validities of outcomes have been shown.

Similar content being viewed by others

References

Lloyd E (1986) An introduction to some metal forming, theory, principles and practice. Portcullis, Redhill

Mohan TR, Misra R (1972) Studies on power spinning of tubes. Int J Prod Res 10:351–364 doi:10.1080/00207547208929937

Hayama M, Kudo H (1979) Analysis of diametrical growth and working forces in tube spinning. Bull JSME 22:776–784

Wang T, Wang ZR, Wang Q et al (1989) The slip line fields of thickness reduction spinning and the engineering calculation of the spinning forces. In: Proceedings of the Fourth International Conference of Rotary Forming, pp 89–93

Singhal PR, Saxena PK, Prakash R (1990) Estimation of power in the shear spinning of long tubes in hard-to-work materials. J Mater Process 23:29–40 doi:10.1016/0924-0136(90)90120-J

Park JW, Kim YH, Bae WB (1997) Analysis of tube spinning processes by the upper bound stream function method. J Mater Process 66:195–203 doi:10.1016/S0924-0136(96)02519-8

Xu Y, Zhang SH, Li P et al (2001) 3D rigid plastic FEM numerical simulation of tube spinning. J Mater Process 113:710–713 doi:10.1016/S0924-0136(01)00644-6

Li K, Hao N, Lu Y et al (1998) Research on the distribution of the displacement in backward tube spinning. J Mater Process 79:185–188 doi:10.1016/S0924-0136(98)00009-0

Paunoiu V, Nicoara D, Teodorescu M (1999) A general upper bound method for forces calculation in tube spinning process. In: Proceedings of the Sixth ICTP, Sept 19–24, Advanced Technology of Plasticity, 1, pp 1095–1100

Ma ZE (1993) Optimal angle of attack in tube spinning. J Mater Process 37:217–224 doi:10.1016/0924-0136(93)90092-K

Yao J, Murata M (2002) An experimental study on paraxial spinning of one tube end. J Mater Process 128(1–3):324–329

Wong CC, Dean TA, Lin J (2003) A review of spinning, shear forming and flow forming processes. Int J Mach Tools Manuf 43:1419–1435 doi:10.1016/S0890-6955(03)00172-X

Chang SC, Huang CA, Yu SY et al (1998) Tube spinnability of AA2024 and 7075 aluminum. J Mater Process 8081:676–682 doi:10.1016/S0924-0136(98)00174-5

Kalpakcioglu S (1964) Maximum reduction in power spinning of tubes, Trans. ASME J Eng Ind 86:49–54

Xu D (1989) Thickness reduction spinning of the thin-walled cylinder with inner stiffness. In: Proceedings of the Fourth International Conference of Rotary Forming, Oct 17–21, pp 97–102

Kalpakcioglu S (1961) On the mechanics of shear spinning. Trans ASME J Eng Ind 83:125–130

Honglie X, Wengang F (1989) A research on the spinnability of normal steel castings. In: Proceedings of the Fourth International Conference of Rotary Forming, Oct 17–21, pp 89–93

Jahazi M, Ebrahimi G (2000) The influence of flow-forming parameters and microstructure on the quality of a D6ac steel. J Mater Process Technol 103:362–366 doi:10.1016/S0924-0136(00)00508-2

Sun JS, Lee KH, Lee HP (2000) Comparison of implicit and explicit finite element methods for dynamic problems. J Mater Process Technol 105:110–118 doi:10.1016/S0924-0136(00)00580-X

Taylor LM, Flanagan DP (1989) PRONTO3D A three dimensional transient program. Sandia report: SAND87-1912, UC-32

Poorganji B (2003) Investigation of chemical composition and microstructure effects on flow formability of high strength steels. M.Sc. Thesis, University of Tehran

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parsa, M.H., Pazooki, A.M.A. & Nili Ahmadabadi, M. Flow-forming and flow formability simulation. Int J Adv Manuf Technol 42, 463–473 (2009). https://doi.org/10.1007/s00170-008-1624-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1624-0